Water Pressure Testing Chamber 10Mpa/20L (Stainless Steel)

BS-TAE-WPTCH-SSX-10A1

Additional Units Made to Order - Ships in 8-10 Weeks

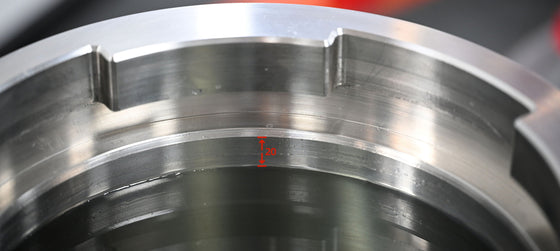

This stainless steel Water Pressure Testing Chamber is a professional-grade hydrostatic test apparatus designed to simulate underwater pressures up to 10 MPa (equivalent to 1,000 m depth). It is ideal for validating the pressure tolerance and watertightness of underwater components, including enclosures, cable penetrators, and other subsea hardware.

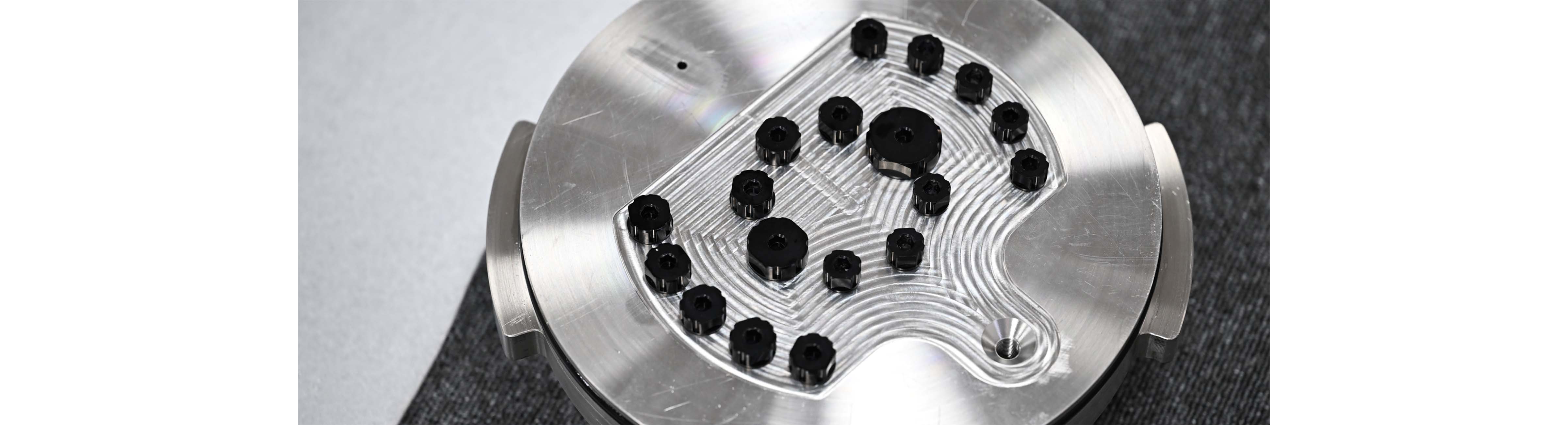

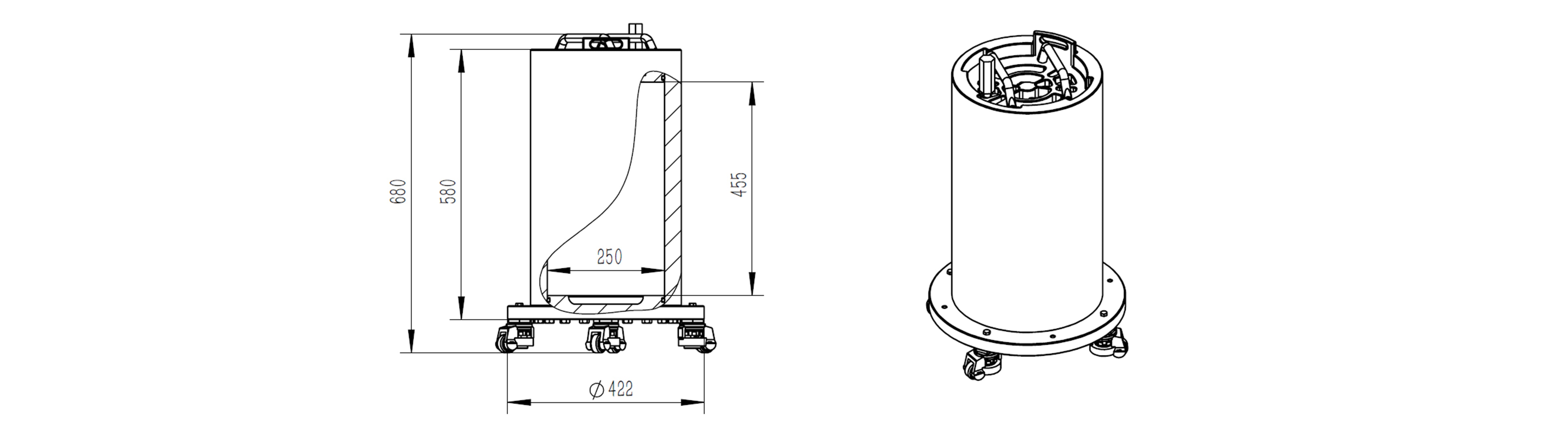

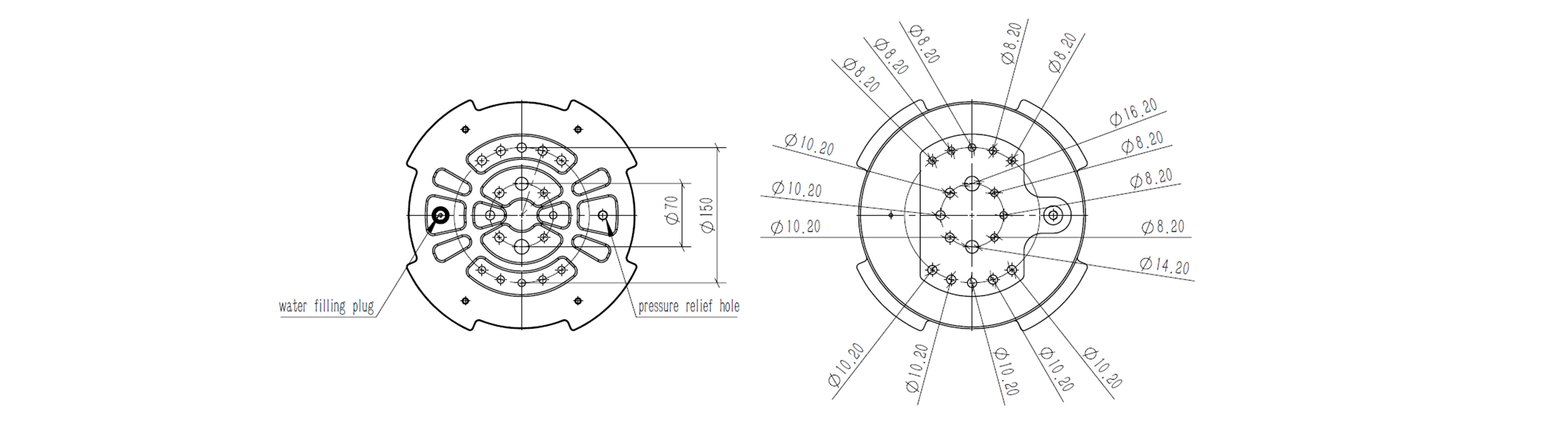

The system includes a large-capacity 20 L pressure chamber, a manual hydraulic pump, and a hatch cover with 18 penetrator-compatible openings for powering or monitoring test items in real time. Integrated features like high-strength handles, safety ratchets, and mobile fulcrum wheels make operation secure and manageable, though the overall unit weighs approximately 200 kg and requires appropriate lifting equipment. This unit is intended for professional use only and requires familiarity with hydraulic safety protocols.

SHIPPING: This item requires special shipping arrangements. Checkout will not charge shipping, but this does not mean shipping is free. We will contact you with a quote after purchase, or you may contact us in advance at contact@blu-sub.com to discuss shipping options.

| Material | 316 Stainless Steel (Chamber & Hatch Cover) |

|---|---|

| Weight | ≈200 kg |

| Color | Stainless Steel |

| Depth Rating | Withstands internal pressure equivalent to 1,000 m / 3,280 ft (10 MPa) |

| Dimensions | Internal Height: 455 mm / Inner Diameter: 250 mm |