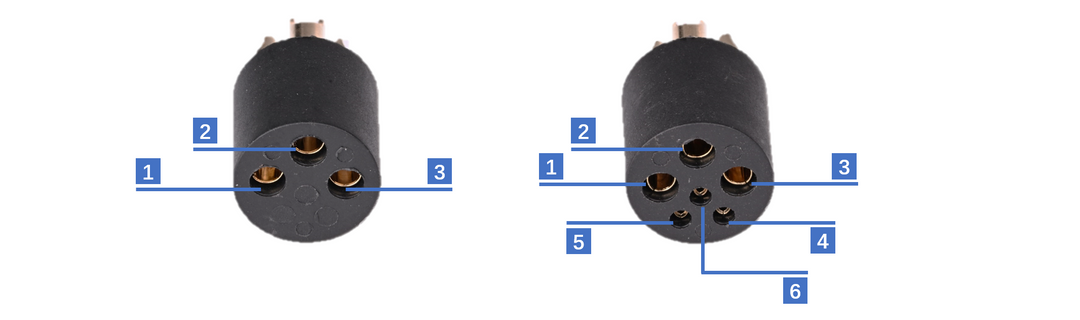

This underwater connector is a dry-mate solution rated for use at depths up to 1,000 meters. It is intended to be fully mated in air prior to submersion and is designed to support reliable power or signal transfer through gold-plated contacts. The system accommodates both 3-pin and 6-pin configurations and is built for compatibility across a range of modular subsea assemblies.

Each connector features a hard-anodized aluminum housing with precision o-ring grooves to ensure watertight integrity. The cable sockets & plugs are user-assembled and must be sealed internally with adhesive — typically a marine-grade epoxy such as Loctite Epoxy Marine. Connectors must either be fully mated or sealed with a Dummy Sealing Cap to remain waterproof under pressure.

Sold Separately

Blu-Sub Male Plugs and Female Sockets are designed to work with the Deep-Sea Underwater Cable for reliable power and signal transmission in underwater environments. Refer to the technical specifications for cable size guidelines. Third-party cables may also be used if they fall within the supported dimensions — check the specifications or contact us for compatibility assistance.

Sold Separately

Blu-Sub 3-pin and 6-pin Male Plug connectors are designed to thread directly into our Deep-Sea M10 Bulkhead connectors, forming a secure, watertight connection between internal and external cables. This setup is ideal for enclosure walls or pass-through panels, allowing for easy disconnection in the field without disturbing sealed internals.

Sold Separately

Deep-Sea Dummy Sealing Caps are available in both male and female versions, designed specifically to mate with Deep-Sea Cable Connectors – Male Plugs and Female Sockets. They are offered in shorting and non-shorting variants to suit different operational needs. These caps help protect unused connectors by maintaining watertight integrity and shielding contact surfaces from moisture, pressure, and debris during storage or partial deployment.

| Deep-Sea Cable Connectors – Female Sockets & Male Plugs | Assembled or Not | OD of the Adapter Cable | Weight |

|---|---|---|---|

| 3pin Male Cable Plug | Requires Assembly | Ø5–Ø8 | 20g |

| 6pin Male Cable Plug | Requires Assembly | Ø5–Ø8 | 20g |

| 3pin Female Cable Socket | Requires Assembly | Ø5–Ø8 | 22g |

| 6pin Female Cable Socket | Requires Assembly | Ø5–Ø8 | 23g |

| SPEC | 3 PIN | 6 PIN |

|---|---|---|

| Core Rated Voltage | 500VAC | 500VAC |

| Core Rated Current | 15A(16AWG) | 15A(16AWG)+3A(24AWG) |

| Insulation Resistance | ≥10MΩ | ≥10MΩ |

| Contact Resistance | ≤10mΩ | ≤10mΩ |

| Operating Temperature | -25~70℃ | -25~70℃ |

| Maximum Wire Diameter | 16AWG | 16AWG+24AWG |

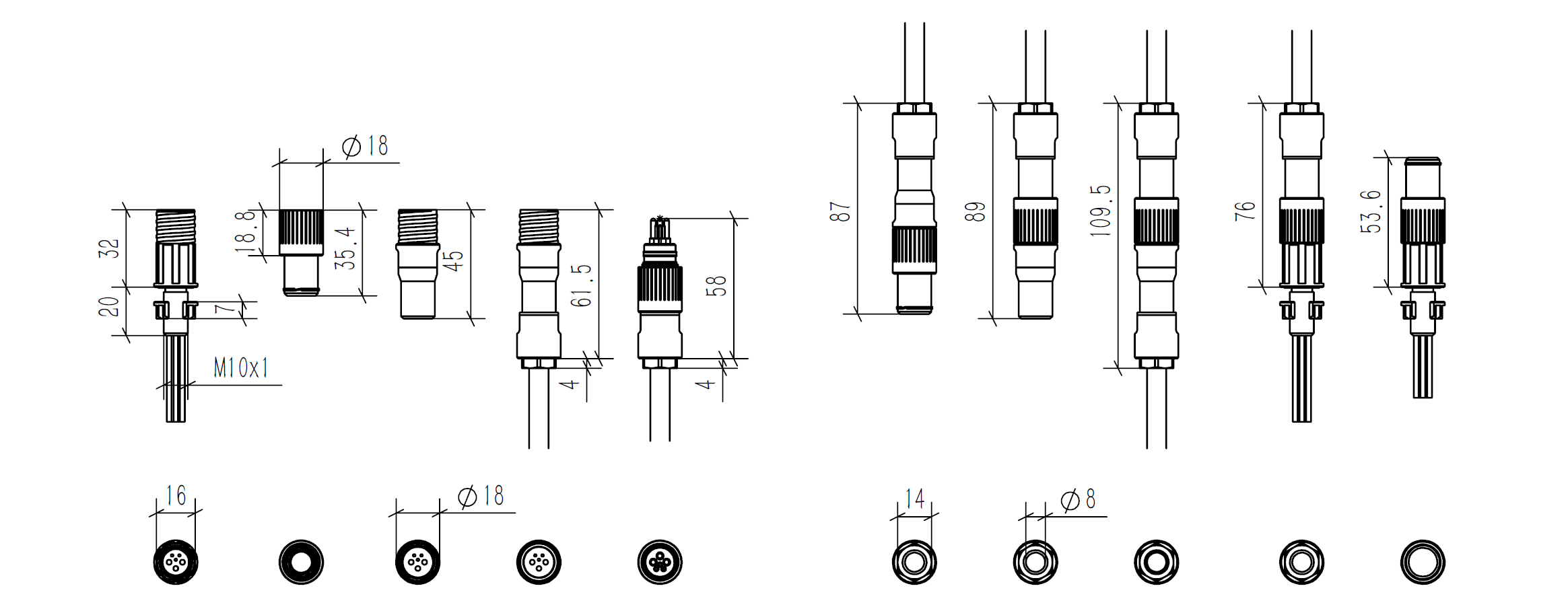

Dimension drawing provided below. It includes all parts in our Deep-Sea Cable Connectors lineup, including Deep-Sea Cable Connectors – Female Sockets & Male Plugs, Deep-Sea Cable Connectors – M10 Bulkheads, and Deep-Sea Cable Connectors – Dummy Sealing Caps.

What are dry mate and wet mate connections?

Dry mate refers to connections that can only be inserted and removed in air. They need to be fully connected to provide waterproofing and ensure the pins are not exposed to water.

For instance, the female socket must be connected to a male plug or dummy plug to be waterproof. Similarly, a male plug must connect to a female socket or dummy plug for waterproofing.

How do they differ from traditional rubber-sealed connectors?

Deep-Sea Cable Connectors allow for self-assembly of wiring, similar to waterproof aviation plugs, but are suitable for deep water use.

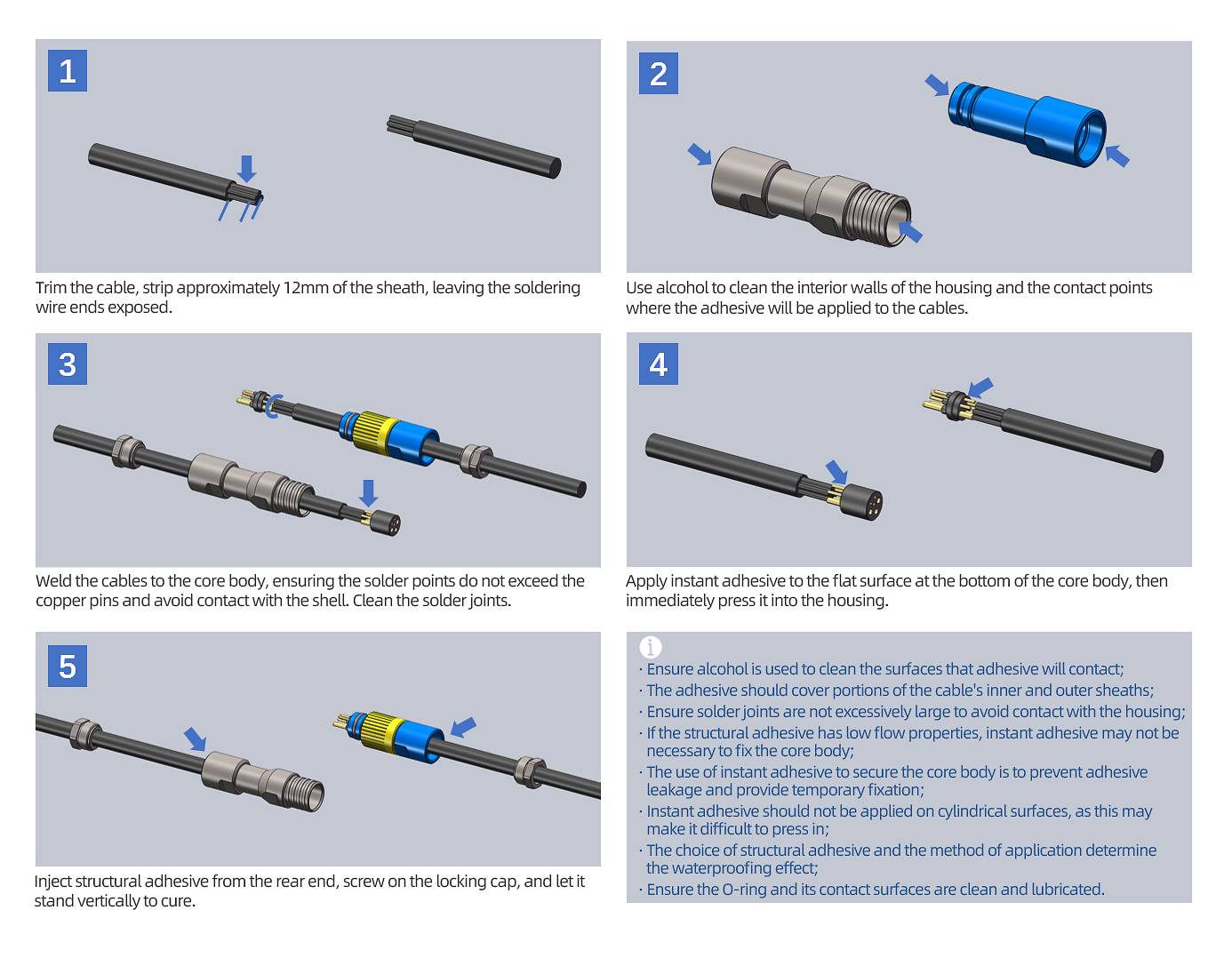

What tools and materials are needed for assembly?

1. Compatible cables

2. Soldering iron

3. Wire strippers

4. Isopropyl alcohol and lint-free cloth

5. Epoxy resin or other sealing adhesives

Which factors affect waterproofing depth during assembly?

1. Type of adhesive used

2. Material of cables used

3. Quality of cleanliness during preparation

What factors affect waterproof performance after assembly?

1. Surface condition of the sealing ring contact area (e.g., wear or scratches)

2. Aging or damage to the sealing ring

3. Overall quality of the connection

Why are the connectors very astringent and difficult to plug?

If no grease is present on the O-ring, it is recommended to apply O-Ring Lubricant - MOLYKOTE® 111 Compound to reduce friction and assist with assembly.