The 115 mm Subsea Optical Glass Flange & End-Cap features a thick borosilicate glass window permanently bonded to a black anodized aluminum flange for strength, clarity, and sealing performance. With 95% light transmittance, 12 mm glass thickness, and a 300 m (984 ft) depth rating, it’s ideal for cameras, lights, and inspection systems.

The integral flange design simplifies assembly—no separate flange is required. A recessed O-ring groove ensures even compression, and eight M3 countersunk mounting holes allow secure installation with a flush finish.

This unit is fully compatible with the Subsea Enclosure Acrylic Tube and Subsea Enclosure Aluminum Tube, both of which support the correct sealing interface. Use only with clean, undamaged O-rings to maintain watertight performance.

Installation and Maintenance Tips: Whether installing into an aluminum or acrylic tube, it is critical to thoroughly lubricate all O-rings with a high-quality compound like O-Ring Lubricant – MOLYKOTE® 111 Compound before inserting the end-cap. Proper lubrication helps prevent damage to the O-rings, the end-cap, and the tube itself, and greatly reduces the risk of leaks. Do not attempt to force the end-cap into place if the O-rings are dry or not fully lubricated, as this can lead to deformation or tearing of the O-rings and may permanently damage the sealing surfaces.

Sold Separately

The Subsea Enclosure Aluminum Tube is fully compatible with the Subsea Optical Glass Flange & End-Cap – 115 mm, which includes an integral flange for direct mounting and sealing.

Made from black anodized aluminum, the Subsea Enclosure Aluminum Tube offers excellent corrosion resistance, high structural strength, and thermal conductivity. It is well-suited for deep-sea systems, heat-generating electronics, and harsh marine environments.

This enclosure is depth-rated to 1,000 m / 3,281 ft, making it ideal for ROVs, sensor pods, and extended underwater deployments where durability and sealing performance are critical.

Sold Separately

The Subsea Enclosure Acrylic Tube is fully compatible with the Subsea Optical Glass Flange & End-Cap – 115 mm, which includes an integral flange for direct sealing and attachment—no separate flange is required.

Made from clear cast acrylic, the tube offers excellent optical clarity, chemical resistance, and dimensional stability—ideal for visual payloads, sensor housings, and inspection systems where monitoring internal components is essential.

This enclosure is depth-rated from 20 m to 250 m / 66 ft to 820 ft, depending on diameter and length. It is best suited for shallow to mid-depth subsea applications where internal visibility and reliable sealing are critical.

Sold Separately

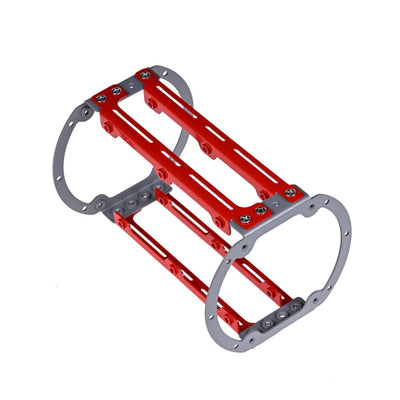

Electronic Tray Set for Enclosure Tube

Offers a structured and secure platform for mounting internal electronics, batteries, and PCB assemblies inside Blu-Sub enclosures. Designed for use with 85 mm, 115 mm, and 165 mm tubes, the tray system includes base mounts, shelf supports, and all required hardware. When used with the Subsea Optical Glass Flange & End-Cap, the base mount attaches directly to the aluminum flange using screws—ensuring stable and precise support for internal components. Compatible with both acrylic and aluminum tubes, the tray system enables efficient internal layout of subsea electronics.

| Spec | 115 mm Glass Flange End Cap |

|---|---|

| Material | Black anodized aluminum + high borosilicate glass |

| Recessed Step | Yes – ensures smooth O-ring contact |

| Screw Holes | Countersunk; screws do not protrude |

| Variants | Only 8-hole pattern available |

| Compatible Tube Size | 115 mm outer diameter only |

| Glass Thickness | 12 mm |

| Glass Bending Strength | Average value 100 MPa |

| Glass Hardness | Mohs hardness grade 7 |

| Transmittance | 95% |

| Glass Material | High borosilicate with high temperature resistance |

| Pressure Resistance Depth | 300 meters |

| Hole Details | 8×Ø3.1 mm countersunk holes on 108 mm circle |

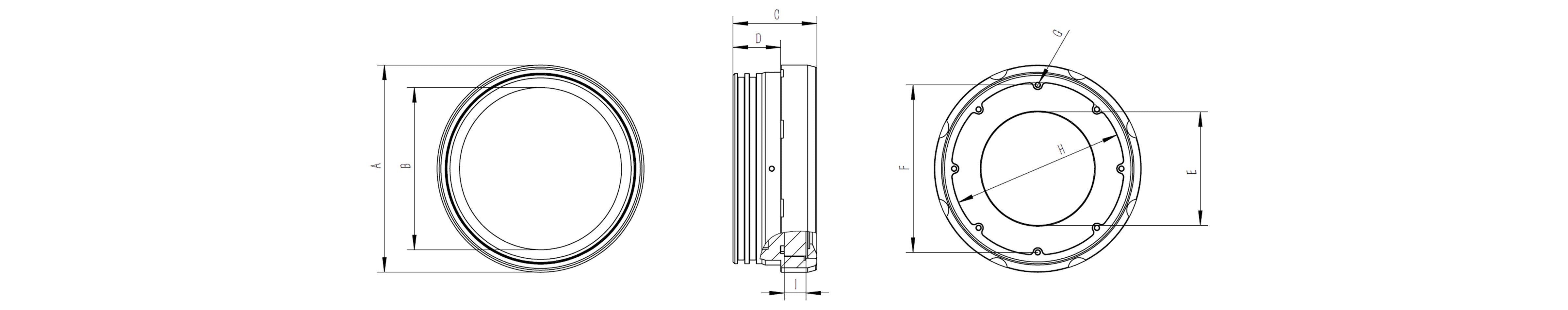

- A: Outer Diameter – Ø115 mm

- B: Pressure Ring Inner Diameter – Ø90 mm

- C: Total Height – 46.5 mm

- D: Piston Height – 26.5 mm

- E: Visual Diameter – Ø63 mm

- F: Internal Mounting Hole Distance – Ø93 mm

- G: Mounting Holes – 8×M3

- H: Inner Diameter – Ø95.5 mm

- I: Glass Thickness – 12 mm

- Side-threaded Hole: M3

Can the end cap be used with vacuum or pressure testing?

Yes — the design supports both vacuum and pressure testing when installed properly using a suitable O-ring and clamping method. Ensure that the O-ring groove and sealing surfaces are clean and undamaged before use.

Is the glass chemically strengthened?

No — the glass is not chemically strengthened. It is precision-machined from borosilicate glass, which offers excellent strength and thermal resistance but should still be handled with care to avoid edge damage or impact.

What sealing method is recommended?

Use a high-quality O-ring matched to the groove dimensions on the end cap and tube. A compatible lubricant may be applied to aid installation, reduce contamination, and improve sealing performance.

Can I use this end cap with non-Blu-Sub aluminum tubes?

The flange end cap is specifically designed for Blu-Sub aluminum subsea tubes. While it may fit other systems with matching dimensions, performance and sealing cannot be guaranteed outside Blu-Sub components.

Is the glass optically clear?

Yes — the borosilicate glass is optically clear, making it ideal for vision systems, lights, or camera applications inside subsea enclosures.

Can the glass be removed or replaced?

No — the glass is permanently bonded to the flange and cannot be removed or replaced without special tools and procedures. Attempting to disassemble it may result in damage.

What is the difference between this and an acrylic end cap?

Compared to acrylic, the glass flange end cap provides better pressure resistance, higher light transmittance, a flatter viewing surface, and greater scratch resistance.

Can I still use the end cap if the O-ring sealing surface is scratched?

No — if the sealing surface is scratched or damaged, the end cap should not be used. Imperfections can lead to seal failure and risk of water ingress under pressure.

Should I apply lubricant to the O-ring during installation?

Yes — applying a compatible lubricant helps remove dust and impurities, allows the O-ring to stay seated in the groove, and improves ease of assembly and sealing effectiveness.