The Subsea Enclosure Acrylic Tube is machined from cast PMMA (acrylic), offering strong optical clarity and excellent mechanical performance for underwater use. Its precision design enables use as an underwater pressure housing or part of an engineered pressure vessel (PV) system. The inner and outer diameters are precisely controlled to ensure a consistent O-ring seal when used with Blu-Sub flanges and end caps.

The outer diameter is machined flat at both ends to allow full-surface contact with the flange’s O-ring interface, improving sealing integrity. The inner diameter is slightly undercut at each end to accommodate O-ring compression and avoid radial interference when inserting flanges. This dual-end machining approach supports repeatable watertight performance under shallow to mid-depth conditions, ideal for small ROV assemblies and custom pressure vessel (PV) configurations.

The acrylic tube provides low moisture absorption and good dimensional stability over time. While not intended for deep-sea use, its strength and stiffness make it a dependable component for moderate-pressure underwater pressure housings. It is compatible with a variety of Blu-Sub flange systems, including the Aluminum End-Cap with the Subsea Aluminum Flange, the Subsea Plastic Flange & End-Cap 115mm, the Subsea Optical Dome End-Cap 115mm, and the Subsea Optical Glass Flange & End-Cap 115mm.

When securing the Subsea Aluminum Flange or any other flange/end-cap assembly to the tube, be sure to thoroughly lubricate all flange O-rings using O-Ring Lubricant – MOLYKOTE® 111 Compound. Proper lubrication ensures smooth installation and prevents O-ring or surface damage, maintaining long-term reliability of the engineered pressure vessel system.

Sold Separately

Subsea Aluminum Flange & Subsea Aluminum End-Cap

Provide a rugged sealing interface for the acrylic tube, using dual o-rings and mechanical compression. We offer several pre-configured hole patterns for common setups, making integration with penetrators and connectors easy. Depth Rating: Up to 1,000 m / 3,281 ft.

Subsea Polymer Flange & End-Cap 115mm

A lightweight and economical option for general-purpose use. Only available for 115 mm tube systems. Depth Rating: Up to 30 m / 98 ft.

Subsea Optical Dome Flange & End-Cap 115mm

Provides a wide-angle acrylic viewing dome for underwater vision systems requiring minimal distortion. Only available for 115 mm tube systems and requires the Subsea Aluminum Flange for installation. Depth Rating: Up to 1,000 m / 3,281 ft.

Subsea Optical Glass Flange & End-Cap 115mm

Features a precision optical window for imaging and sensor payloads. Only available for 115 mm tube systems. Depth Rating: Up to 300 m / 984 ft.

Sold Separately

Blu-Sub Enclosure Aluminum Tube

Only available in 115 mm diameter, this rugged aluminum tube is designed for deep-sea use up to 1,000 m / 3,281 ft. It features long-life corrosion-resistant construction, an internal mounting rail system, and a bolt-locking flange design for secure sealing in high-pressure environments.

Blu-Sub Watertight Enclosure Box

Rated to 300 m / 984 ft, this compact aluminum housing is ideal for electronics that require heat dissipation through a direct thermal path. It includes pre-drilled M10 holes for cable penetrators and structural mounting, and is built for durability in subsea deployments where space and thermal management are key considerations.

Sold Separately

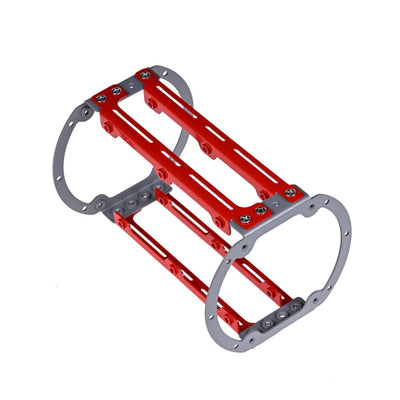

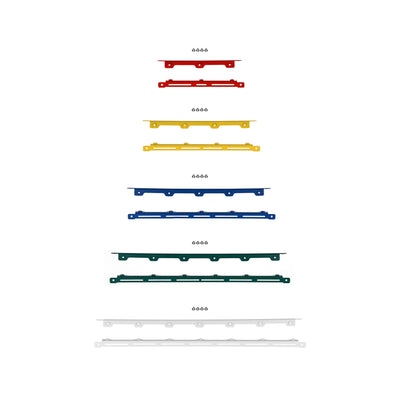

For secure mounting of your acrylic housing, the Subsea Acrylic Tube Clamp Set offers a reliable solution. Specifically designed for use with Blu-Sub Acrylic Tubes, these anodized aluminum clamps are available for 85 mm, 115 mm, and 165 mm diameters. Each clamp features a split-ring design with multiple M5 mounting holes and includes soft anti-slip pads to prevent rotation and slippage during deployment. Ideal for attaching enclosures to trays, plates, or frame structures.

Sold Separately

Electronic Tray Set for Enclosure Tube

Provides a modular mounting system for internal electronics, batteries, and PCBs within Blu-Sub enclosures. Available for 85 mm, 115 mm, and 165 mm tubes, the tray includes base mounts, shelf supports, and mounting hardware. It is fully compatible with both acrylic and aluminum tube housings, allowing for structured and secure component layout.

Insulated PCB Board Shelf for Enclosure Tube

For simplified circuit mounting and layout planning, this shelf is designed to fit directly into the tray set using single-point or double-point shelf supports. Made from green, double-sided electrically insulated PCB material, it includes pre-marked point holes to assist with component drilling, pass-throughs, and cable routing.

Sold Separately

Blu-Sub offers two compatible solutions for managing pressure equalization, enclosure servicing, and vacuum leak testing. Each option supports different operational needs and levels of sealing performance:

Subsea M10 Self-Sealing Vent & Vacuum Plug

An advanced self-sealing port that allows both vacuum leak testing and retention of negative internal pressure after hose removal. The internal valve and lock cap maintain vacuum post-disconnection, making it ideal for preventing condensation or stabilizing pressure. Includes bulkhead, copper vacuum plug, and lock cap. Rated to 1,000 m / 3,280 ft. Applying negative pressure can also help hold the enclosure closed, improving seal performance during storage or deployment.

Subsea M8 Vent & Vacuum Plug

A compact two-part system for manual venting and temporary vacuum testing. Vacuum must be resealed manually by inserting the plug after test. Best for quick leak checks or venting during servicing. Rated to 1,000 m / 3,280 ft. Brief vacuum pressurization can assist with pulling flanges tight or holding enclosure lids shut prior to fastener installation.

| Item | Material | Depth Rating | Weight |

|---|---|---|---|

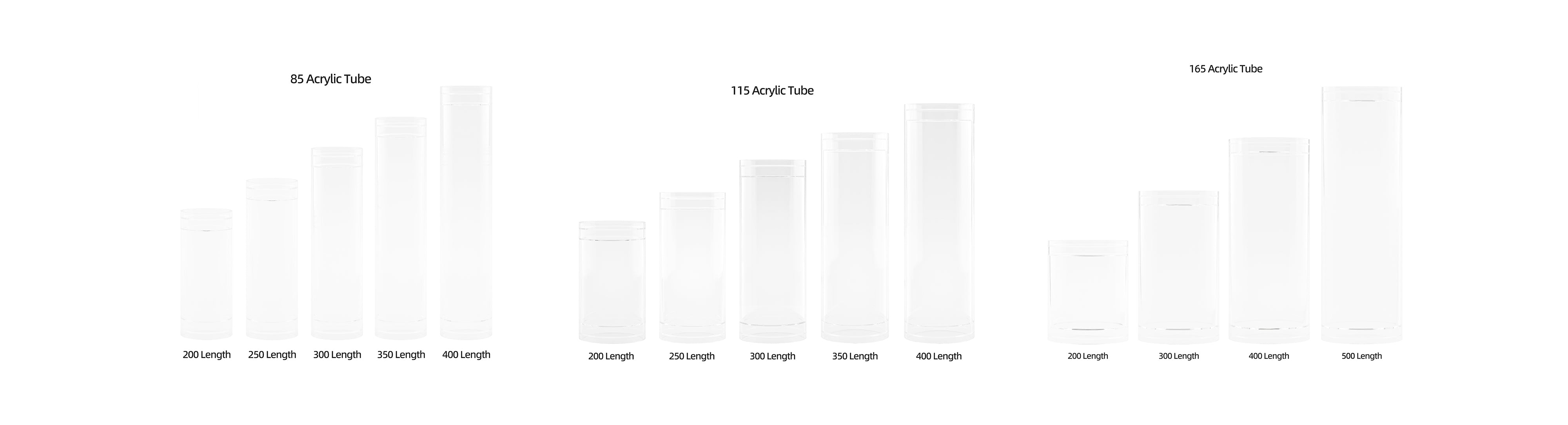

| 85 Acrylic Tube /200 Length | Clear Acrylic | 250 meters / 820 ft | 316g |

| 85 Acrylic Tube /250 Length | Clear Acrylic | 200 meters / 656 ft | 400g |

| 85 Acrylic Tube /300 Length | Clear Acrylic | 150 meters / 492 ft | 485g |

| 85 Acrylic Tube /350 Length | Clear Acrylic | 140 meters / 459 ft | 570g |

| 85 Acrylic Tube /400 Length | Clear Acrylic | 130 meters / 427 ft | 651g |

| 115 Acrylic Tube /200 Length | Clear Acrylic | 180 meters / 591 ft | 460g |

| 115 Acrylic Tube /250 Length | Clear Acrylic | 150 meters / 492 ft | 578g |

| 115 Acrylic Tube /300 Length | Clear Acrylic | 130 meters / 427 ft | 737g |

| 115 Acrylic Tube /350 Length | Clear Acrylic | 100 meters / 328 ft | 831g |

| 115 Acrylic Tube /400 Length | Clear Acrylic | 90 meters / 295 ft | 962g |

| 165 Acrylic Tube /200 Length | Clear Acrylic | 100 meters / 328 ft | 693g |

| 165 Acrylic Tube /300 Length | Clear Acrylic | 80 meters / 262 ft | 1092g |

| 165 Acrylic Tube /400 Length | Clear Acrylic | 50 meters / 164 ft | 1495g |

| 165 Acrylic Tube /500 Length | Clear Acrylic | 20 meters** / 66 ft** | 1900g |

* Pressure-resistant depth retains a margin of safety, but should be less than 300 hours in the vicinity of the rated depth. For long-term use at the rated depth, it is advisable to use Blu-Sub’s enclosure aluminum tubes. The rated depth data refers to the pressure-resistant depth without vacuum evacuation.

** The rated pressure depth of the 165×500 specification is estimated. Due to the limited size of the pressure test equipment, this specification has not been tested.

SPECIAL NOTE: Acrylic products should not come into contact with alcohol, do not touch any kind of alcohol or alcohol derivatives or the acrylic tube will break and fail! Do not clean any acrylic with alcohol either! Use only water or acrylic safe cleaners. Alcohol, solvents and harsh cleaners will crack and damage the material! Most threadlockers are chemically incompatible with plastics and will also damage acrylic!

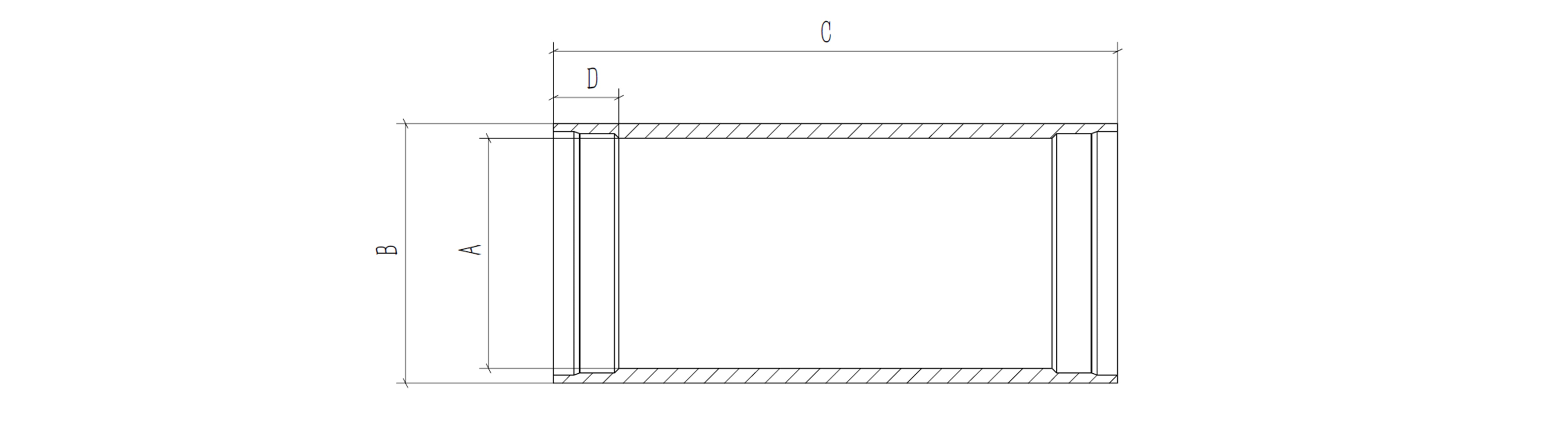

| Item | Inner Diameter (A) | Outer Diameter (B) | Length (C) | Piston Hole Depth (D) |

|---|---|---|---|---|

| 85 Enclosure Acrylic Tube | 73 mm | 85 mm | Total Length ±1 mm | 28.5 mm |

| 115 Enclosure Acrylic Tube | 102 mm | 115 mm | Total Length ±1 mm | 29 mm |

| 165 Enclosure Acrylic Tube | 151 mm | 165 mm | Total Length ±1 mm | 29.5 mm |

Why should it be used for less than 300 hours at rated depth?

The 300-hour guideline applies when operating at the **maximum rated depth** for the acrylic tube, as specified in the specification table above. At that depth, prolonged exposure may lead to material creep and increased risk of leakage. However, if operated at shallower depths or used as an underwater pressure housing within its rated limits, the tube's lifespan is significantly extended and long-term use is generally not an issue.

Why are there precision-machined steps at both ends of the tube?

Standard acrylic tubes often lack the roundness and precision necessary for reliable sealing. Precision machining ensures a smooth, round surface for proper O-ring compression and consistent sealing performance in engineered pressure vessel (PV) assemblies.

Can it still be used if the O-ring contact surface is scratched?

No. Any damage to the O-ring contact surface may compromise sealing and create a risk of leakage. It should not be used if scratched, especially in applications where it serves as part of a sealed pressure vessel (PV) system.

Can custom lengths be requested?

Yes. Custom lengths can be produced for an additional fee, though longer lengths may reduce pressure resistance. Lead times may vary depending on the order and whether the tube is configured for use as an engineered pressure vessel or standard subsea enclosure.

Are other internal and external diameter sizes available?

Yes. Additional sizes are in active development and production for a range of underwater pressure housing and subsea enclosure applications. Please inquire for availability or custom requests.

Are they compatible with Blu-Sub Aluminum Enclosure Tubes?

Yes. These tubes are compatible with Blu-Sub Aluminum Enclosure Tubes and can be directly interchanged, allowing flexible integration across pressure vessel (PV) configurations. Note: internal volume and dimensions may differ slightly.

Why not use PC (polycarbonate) material instead of acrylic?

Under specific conditions, tested acrylic tubes outperformed polycarbonate in sealing and deformation resistance, making them better suited for engineered pressure vessel and submersible enclosure applications.

Why are there no holes on the sides to mechanically lock the flange?

The Blu-Sub Acrylic Enclosure Tube does not include side locking holes by design. Sealing is achieved via flange friction, external water pressure, and optional vacuum retention using the Blu-Sub Vacuum Plug Kit. This design consistently maintains sealing integrity in normal use. When assembled, the enclosure performs as an underwater pressure housing, remaining sealed under external pressure. Applying a slight vacuum significantly increases holding force. If a lockable option is required, the Blu-Sub Aluminum Enclosure Tube includes mechanical locking features for enhanced pressure vessel configurations.