The Subsea Optical Dome End-Cap is a precision-engineered optical dome made from high-clarity polycarbonate (PC), specifically developed for subsea imaging and sensing applications at depths up to 1,000 meters. Its optical-grade material and dome geometry are manufactured under cleanroom conditions to ensure superior clarity, dimensional stability, and pressure tolerance. The dome provides an ideal viewing window for wide-angle cameras or gimbals, helping to minimize optical distortion, eliminate the underwater magnification effect seen with flat acrylic end caps, and reduce drag in high-flow environments.

This product is available exclusively in the 115 mm diameter size and is designed to integrate seamlessly with the Subsea Aluminum Flange. The flange includes a threaded recess into which the included Retaining Ring secures the dome with eight evenly spaced mounting screws. This mechanical interface ensures a reliable and reusable seal using a standard O-ring groove, while also protecting the dome during installation and removal.

Once assembled with the flange, the full system is compatible with both the Subsea Enclosure Acrylic Tube and the Subsea Enclosure Aluminum Tube, making it fully modular across different housing materials. The design allows for excellent camera visibility and environmental durability, supporting advanced underwater ROVs, observation systems, or sensor pods.

The dome is offered in three configurations:

- Optical Dome End-Cap 115 mm (dome only)

- Optical Dome End-Cap 115 mm with Retaining Ring (dome + retaining ring + screws)

- Retaining Ring for Dome End-Cap 115 mm (ring only for replacement or spare)

Each option enables flexible integration depending on whether a new build or replacement part is needed.

Sold Separately

The Subsea Optical Dome End-Cap must be used with a Retaining Ring to create a secure and reusable seal. The Retaining Ring is included in select dome options and threads directly into the Subsea Aluminum Flange.

This flange provides the required mounting interface and facilitates compatibility with both the Subsea Enclosure Acrylic Tube and the Subsea Enclosure Aluminum Tube, allowing for flexible housing builds.

This dome is currently available only in the 115 mm diameter version.

Sold Separately

The Subsea Enclosure Aluminum Tube is fully compatible with the Subsea Optical Dome End-Cap – 115 mm when paired with the Subsea Aluminum Flange.

The Subsea Aluminum Flange provides a precision-threaded mounting interface and dual o-ring sealing system to secure the dome and maintain watertight integrity under extreme pressures.

Made from black anodized aluminum, the Subsea Enclosure Aluminum Tube offers excellent corrosion resistance, high structural strength, and thermal conductivity. It is well-suited for deep-sea systems, heat-generating electronics, and harsh marine environments.

This enclosure is depth-rated to 1,000 m / 3,281 ft, making it ideal for ROVs, sensor pods, and extended underwater deployments where durability and sealing performance are critical.

Sold Separately

The Subsea Enclosure Acrylic Tube is fully compatible with the Subsea Optical Dome End-Cap – 115 mm when paired with the Subsea Aluminum Flange.

The Subsea Aluminum Flange provides the threaded mounting and sealing interface required to integrate the dome securely. Its dual o-ring grooves and rigid structure ensure watertight performance under pressure when used with properly machined acrylic tube ends.

Only the 115 mm diameter version of the Subsea Enclosure Acrylic Tube is supported for this setup. Smaller or larger diameter tubes are not compatible with the flange or dome system.

Made from clear cast acrylic, the Subsea Enclosure Acrylic Tube offers excellent optical clarity, chemical resistance, and dimensional stability. It is ideal for visual payloads, sensor housings, and shallow to mid-depth underwater systems where monitoring internal components is critical.

This enclosure is depth-rated from 20 m to 250 m / 66 ft to 820 ft, depending on diameter and length. It is best suited for applications that do not require extreme pressure resistance but still demand reliable sealing and structural integrity.

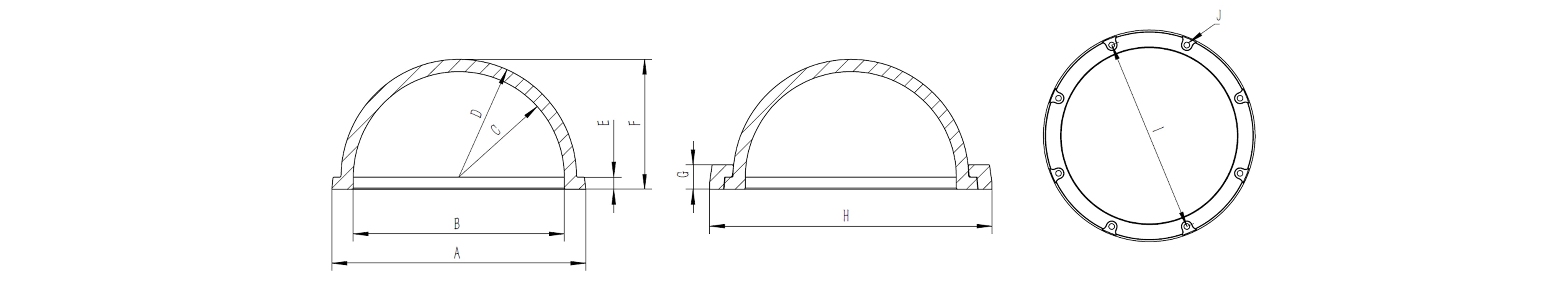

| Outer Diameter (A) | 103.4 mm |

| Inner Diameter (B) | 86 mm |

| Inner Radius (C) | R43 |

| Outer Radius (D) | R48 |

| Flange Thickness (E) | 5 mm |

| Overall Height (F) | 53 mm |

| Retaining Ring Height (G) | 10 mm |

| Retaining Ring Outer Diameter (H) | 115 mm |

| Distance Between Retaining Ring Holes (I) | 106.7 mm |

| Retaining Ring Screws (J) | 8 × Ø3.1 mm |

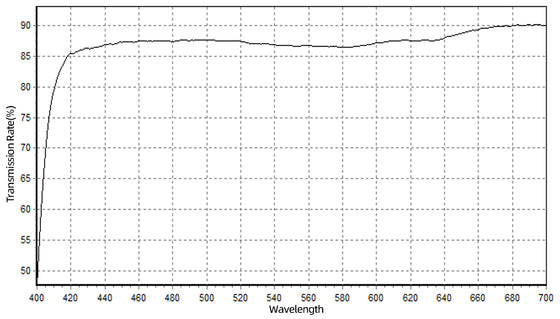

This chart below shows the transmission rate of the dome material across the visible light spectrum (400–700 nm). The material demonstrates excellent optical clarity, with an average transmission rate of 86.68% across the visible range.

Transmission increases sharply at the lower end of the spectrum and remains consistently above 85% throughout. This high level of light transmission makes the dome suitable for wide-angle imaging, optical sensors, and underwater vision systems.

What is the transmission rate?

Average (Tavg @400–700 nm): 86.68%

Why use a dome instead of a clear acrylic end cap?

- Allows wide-angle lenses to operate without obstruction

- Provides internal clearance for rotating gimbals

- Minimizes the magnifying refraction effect compared to flat acrylic caps

- Reduces hydrodynamic drag

- Offers improved pressure resistance

- Higher dimensional and optical precision due to molded optical acrylic

Can it still be used if the contact surface of the O-ring is accidentally scratched?

No. Any damage to the O-ring contact surface may compromise the seal and lead to leakage. The part should be replaced.

Is it compatible with standard aluminum tubes, acrylic tubes, and flanges?

Yes, it is compatible with tubes and flanges of the same diameter and can be used as a direct replacement for flat end caps.

Should grease be applied to the O-rings every time?

Yes. O-ring lubricant helps remove dust and particles, improves adhesion to the groove, and ensures easier and safer assembly.