Subsea Aluminum Flange

BS-SSC-FLNGE-ALU-A1A1

50 Units Available for Quick Ship - Ships in 1-2 Business Days

Additional Units Made to Order - Ships in 2-4 Weeks

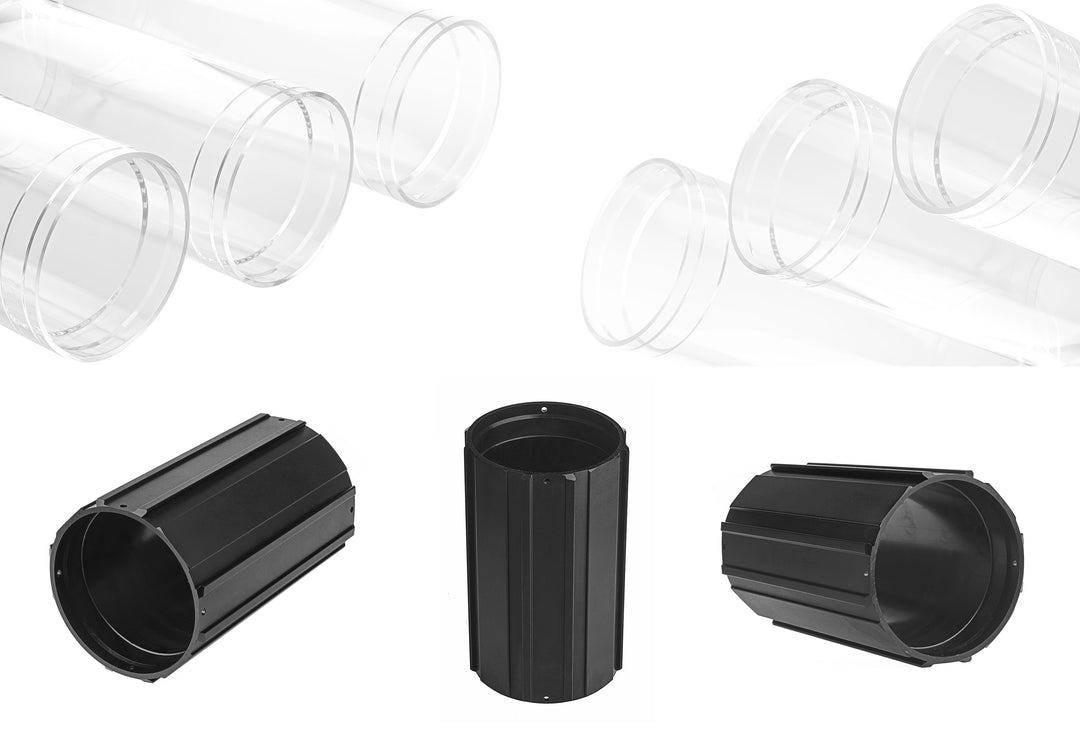

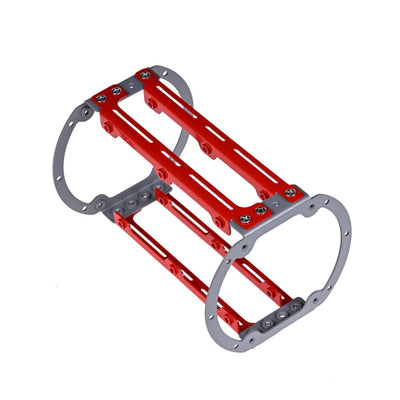

The Blu-Sub Aluminum Flange is a critical sealing and structural component for building custom underwater enclosures using either Subsea Enclosure Acrylic Tubes or Subsea Enclosure Aluminum Tubes. This flange must be paired with a compatible end-cap, such as the Subsea Aluminum End-Cap or the Subsea Optical Dome End-Cap, to create a secure, watertight seal. Because neither the acrylic nor aluminum tubes have integrated sealing edges or O-ring grooves, the flange provides the essential interface required for proper enclosure assembly.

On the Subsea Enclosure Aluminum Tube, side-threaded locking ports on the flange interface directly with the tube, offering optional mechanical retention of the end cap and flange. This is especially beneficial for high-vibration conditions or when deploying vertically in tethered systems, where movement or pressurization cycles could otherwise dislodge unfastened components. The aluminum flange secures to the tube using four set screws that engage with these locking ports, providing added safety and reliability for demanding subsea applications.

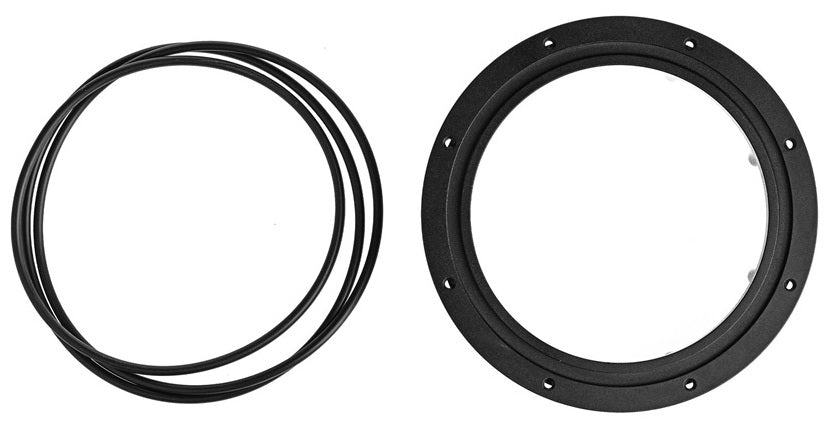

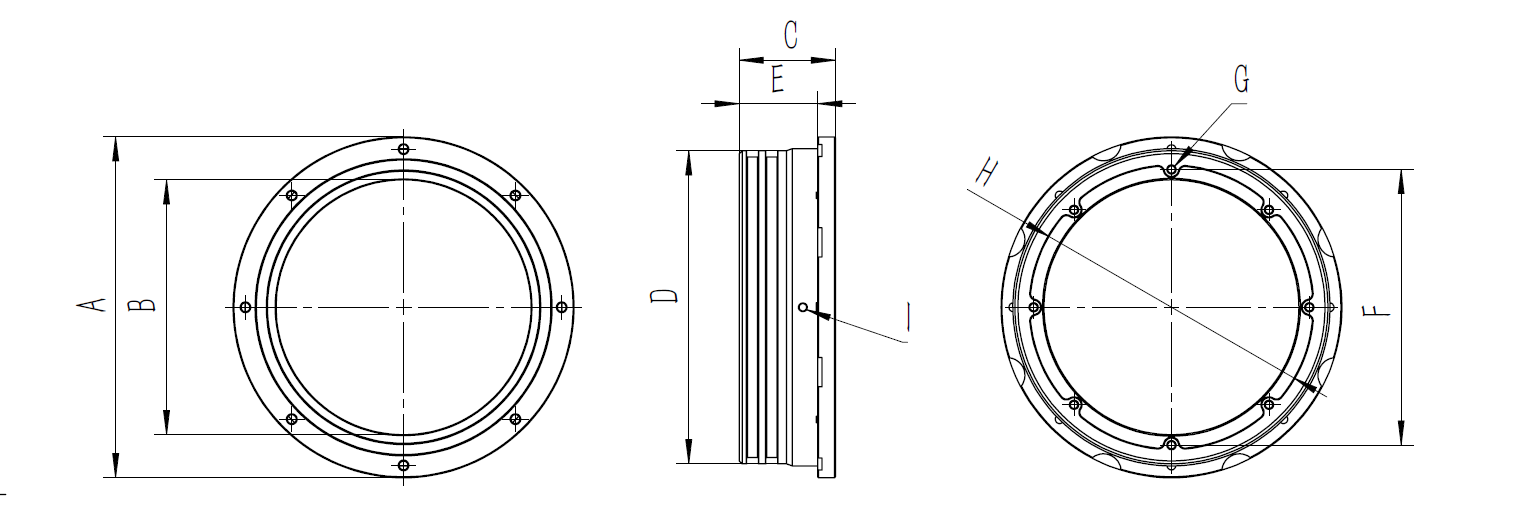

The flange features a double-O-ring design at the tube connection, ensuring a strong and redundant seal between the flange and the enclosure tube. It also includes an integrated O-ring groove for the end-cap, creating a pressure-resistant barrier when the cap is installed. All required O-rings are included with the flange to support immediate installation without additional sealing components.

Once installed over the open end of the tube, the flange forms the mounting surface for the end-cap and houses precision-machined O-ring grooves that ensure a tight, pressure-resistant seal. Standardized screw hole patterns and integrated alignment features support modular builds by allowing reliable disassembly and reassembly. The anodized aluminum construction provides long-term resistance to corrosion and mechanical stress in subsea environments, making this flange suitable for sensor housings, ROV enclosures, data pods, and other marine electronics.

Need Help Building Your Complete System?

Use our Subsea Enclosure Builder to design your complete underwater system with perfect compatibility, real-time pricing, and one-click ordering.

| Material | Anodized Aluminum |

|---|---|

| Weight |

85 mm: 116 g 115 mm: 190 g 165 mm: 276 g |

| Color | Black |

| Depth Rating | 1,000 m / 3,281 ft |

| Dimensions | Refer to technical specifications |