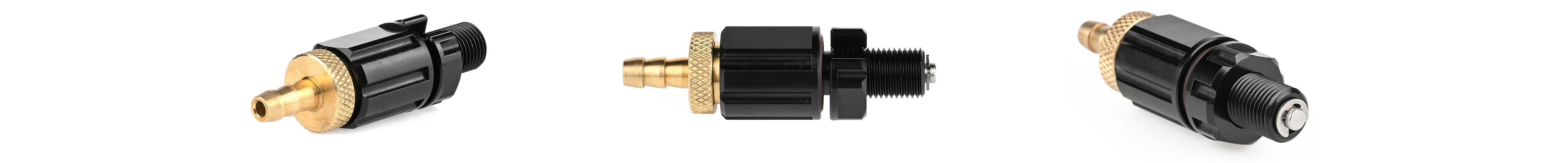

Subsea M10 Self-Sealing Vent & Vacuum Plug is designed to support both vacuum leak testing and the maintenance of internal negative pressure within a sealed subsea enclosure. Its self-sealing design features a copper vacuum plug and lock cap, which together enable the enclosure to retain vacuum pressure even after the vacuum pump is removed. This makes the M10 plug well-suited for use cases where negative internal pressure must be preserved during storage, transit, or deployment — helping prevent condensation, manage pressure differentials during immersion, and reduce the risk of flange detachment.

Unlike the M8 Enclosure Vent & Vacuum Plug, which provides a passive vent and temporary vacuum test capability but does not seal after the pump is disconnected, the M10 plug allows for ongoing pressure isolation. It includes an internal sealing mechanism and a lock cap that must be fully tightened before underwater use to ensure watertight integrity. While both options serve leak testing functions, only the M10 version can maintain negative pressure autonomously without requiring a connected hose or external valve.

A manual vacuum pump is required for both vacuum testing and initial pressure drawdown, but it is not included with this product. The complete M10 assembly consists of a self-sealing bulkhead, a copper vacuum plug, and a threaded lock cap. Once installed, it offers a compact, reusable, and secure method to manage internal enclosure pressure without needing to modify the plug or use adhesives.

Note: Vacuum testing only verifies airtightness and not pressure resistance. For pressure resistance, hydraulic testing is still required.

The Subsea M10 Self-Sealing Vent & Vacuum Plug and the Subsea M8 Vent & Vacuum Plug are both used for vacuum testing subsea enclosures, but serve distinct purposes based on deployment needs and pressure retention requirements.

M10 Self-Sealing Vacuum Plug

Designed for long-term vacuum retention, this plug features an internal valve that seals automatically once vacuum is established. A lock cap further ensures watertight integrity. Ideal for maintaining internal negative pressure during transport, storage, or extended subsea deployment.

M8 Vent & Vacuum Plug

A simpler alternative intended for short-term vacuum leak testing and passive venting. This plug does not retain vacuum once the hose is removed and is better suited for shallow-water or temporary use where long-term sealing is not required.

Key Differences

- Vacuum Retention: M10 seals autonomously after pump removal; M8 requires hose connection to maintain vacuum.

- Application: M10 is suited for long-term or deep-water use; M8 is intended for testing or short-term deployment.

- Components: M10 includes a self-sealing valve and lock cap; M8 uses a simple threaded cap and hose fitting.

- Port Size: M10 uses a larger M10 bulkhead; M8 uses a smaller M8 size fitting.

Sold Separately

The Subsea M10 Self-Sealing Vent & Vacuum Plug integrates into a wide range of Blu-Sub subsea enclosures using a standard M10 bulkhead port. It must be installed into a properly sized through-hole (Ø10.1 ± 0.1 mm) with sufficient panel thickness to ensure a watertight seal. Always ensure the O-ring contact surface is clean and flush prior to vacuum testing.

Subsea Watertight Enclosure Box

Compact aluminum housing rated to 300 m, pre-drilled with twenty M10 ports. Fully compatible with vacuum plug installation—no additional modification required.

Subsea Enclosure Acrylic Tube

Transparent cast acrylic tube rated to 250 m. Compatible with aluminum end-caps that can be drilled with an M10 port to install the vacuum plug for pressure integrity testing.

Subsea Enclosure Aluminum Tube

Rugged enclosure body rated to 1,000 m. Use with Blu-Sub aluminum end-caps featuring an M10 mounting hole for secure integration of the vacuum plug in high-pressure environments.

| Item | Subsea M10 Self-Sealing Vacuum Plug |

| Material | Vacuum Plug: Copper Lock Cap & Body: Aluminum, Plastic |

| Weight | 45 g |

| Pressure Resistance Depth | 1,000 m / 3,280 ft |

| Hose Size | Inner Diameter: 5 mm, Outer Diameter: 8 mm |

| O-ring Size | Ø12 × 1.5 |

| O-ring Material | FKM75 Brown Fluorine Rubber |

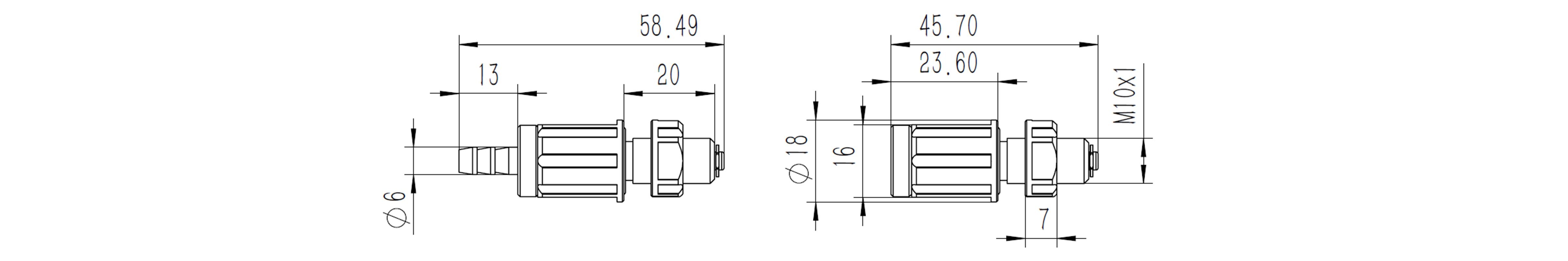

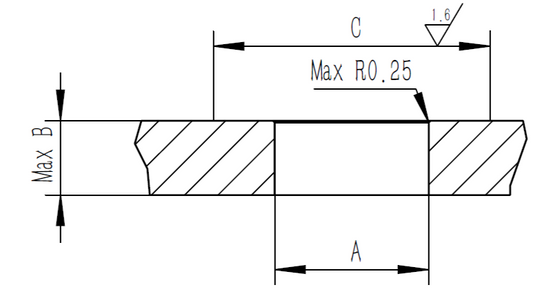

A dimension drawing is provided below. The left diagram shows the dimensions when installing the vacuum plug, while the right diagram illustrates the dimensions when installing the lock cap. Please note that the lock cap must be securely screwed on before the equipment is submerged to ensure waterproofing. Additionally, ensure that the O-ring is lubricated and inspect it for any impurities or scratches.

| Recommended Size | Vacuum Plug |

|---|---|

| Recommended Bulkhead Through Hole Size (A) | Ø10.1 ± 0.1 |

| Hatch Cover Thickness (B) | 13 mm |

| Surface Range (C) | 20 mm |

Vacuum Testing Guide

- Install the self-sealing bulkhead into the enclosure end-cap.

- Seal off the manual vacuum pump and confirm there are no air leaks in the pump body.

- Connect one end of the hose to the manual vacuum pump and the other end to the copper plug.

- Insert the copper plug into the bulkhead and press the pump several times until the plug holds in place under vacuum.

- Continue pumping until the gauge reads approximately 15 inHg, then wait a few minutes.

- Verify the reading does not drop more than 0.5 inHg, indicating a proper seal.

- Remove the vacuum plug and securely screw on the lock cap before submersion.

Can it still be used if the contact surface of O-ring is accidentally scratched?

No, it cannot be used, as there is a risk of leakage.

Whether to apply grease to O-rings every time?

Yes, applying lubricating grease has several benefits: it helps remove dust and impurities from O-rings during application, and allows O-rings to adhere to the groove for easy assembly.

Do I need to tighten the lock cap very tightly?

No, you don't need to tighten it very tightly. Simply ensure the O-ring is fully inserted, then tighten until flush to achieve a good seal.

Why doesn't the vacuum plug have a latch?

When a vacuum is formed, the plug naturally stays in place and won't detach. A latch is unnecessary. Just hold the plug during initial pressing.

If I can't remove the plug after creating a vacuum inside the watertight enclosure, how do I release the air?

You can release the air by pressing downward on the internal step of the plug.

Should I use threadlocker on the nut?

Yes, threadlocker is recommended, as the lock cap is installed by rotation and may loosen over time.

Will water enter if I don't install the lock cap?

Yes, the lock cap must be installed to ensure waterproofing.