This rugged aluminum enclosure is naturally UV-resistant, making it ideal for surface and shallow-water systems exposed to direct sunlight. As an engineered pressure vessel (PV), its corrosion-resistant construction supports a long operational lifespan, even during extended deployment in challenging underwater environments.

Integrated along the enclosure walls are twenty predrilled M10 through-holes, enabling seamless compatibility with Blu-Sub’s suite of M10 cable penetrators and a wide range of subsea components. These include vacuum plugs, subsea switches, potentiometers, signal indicators, displays, environmental sensors, and more—allowing reliable integration of complex electronics without the need for additional modification. The enclosure is designed to simplify the assembly of advanced subsea systems and underwater pressure housing configurations while ensuring durable watertight performance.

Sold Separately

Blu-Sub Enclosure Acrylic Tube

Ideal for visual monitoring and general-purpose subsea builds, Blu-Sub Acrylic Tubes offer crystal-clear visibility and a wide selection of matching flanges and caps. Available in 85 mm, 115 mm, and 165 mm diameters, they are compatible with all standard Blu-Sub enclosure components. Depth Rating: 20 m – 250 m / 66 ft – 820 ft (varies by size and length).

Subsea Enclosure Aluminum Tube

For applications requiring enhanced protection or higher pressure resistance, this aluminum tube offers a robust alternative. It supports larger internal volumes and more size variations, making it well suited for high-density electronics and demanding underwater environments. Compatible with Blu-Sub flanges, end caps, mounting rails, and internal fittings. Available exclusively in 115 mm diameter, with varying tube lengths. Depth Rating: Up to 1,000 m / 3,281 ft.

Sold Separately

This enclosure box includes 20 pre-drilled M10 through-holes, making it fully compatible with a variety of Blu-Sub M10-mountable accessories.

M10 Water Temperature Sensor

Monitors underwater temperature with a waterproof digital sensor head in a compact M10 form factor.

Subsea M10 Depth Sensor

Measures water pressure and calculates depth in real-time, designed for secure M10 integration.

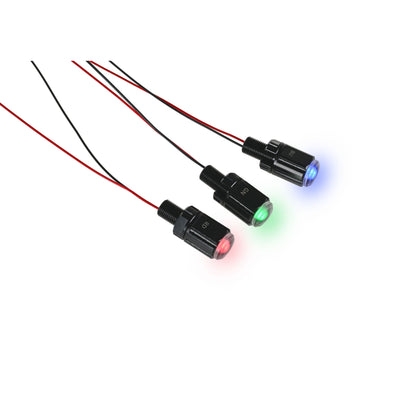

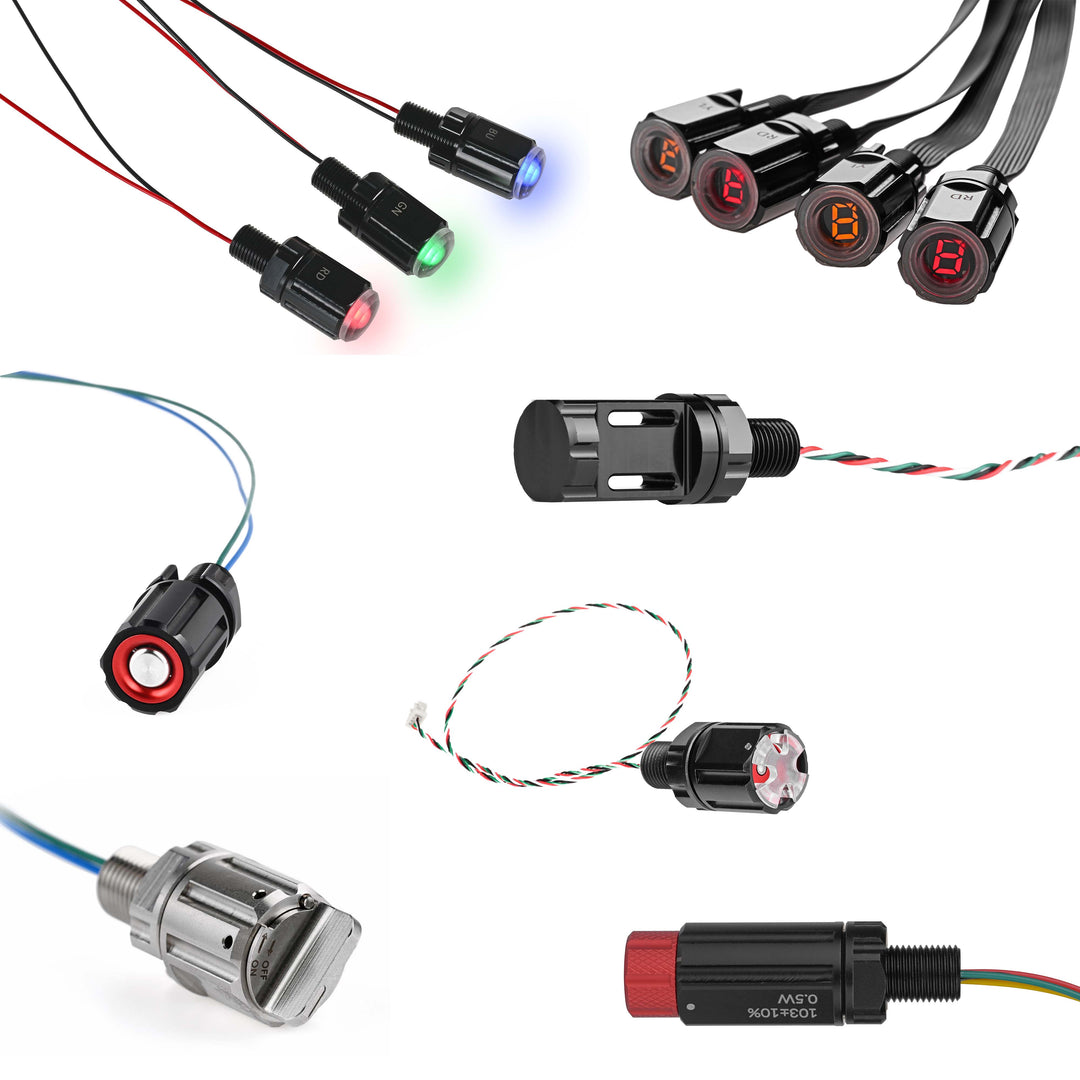

Subsea M10 Signal Indicator

Provides visual status feedback via bright LED indicators housed in a robust M10 fitting.

Subsea M10 7-Segment Display

Displays numbers and codes underwater using a high-visibility M10-mounted LED segment screen.

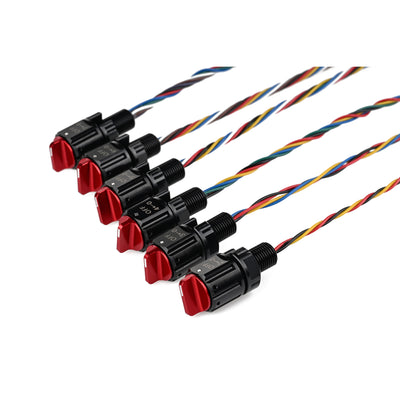

Subsea Switches & Potentiometers

A wide variety of M10-mounted input devices are available, including the Subsea M10 Rotary Potentiometer, Subsea M10 Rotary Waveband Switch, Subsea M10 Tap Switch, Subsea M10 Pressure Trigger Switches, Subsea M10 Rotary On/Off Switch and others.

Sold Separately

For cable power and signal control, the following components support reliable watertight connections through M10 interfaces and compression sealing:

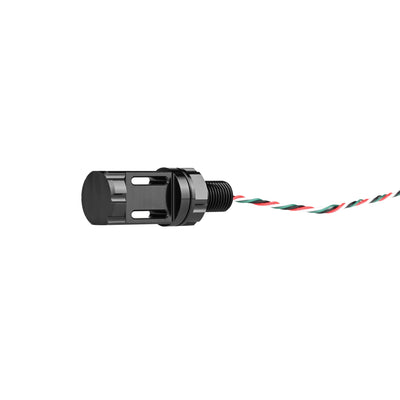

Deep-Sea M10 Gland Cable Penetrator

Designed for deep-water sealing, this penetrator uses compression to maintain a secure watertight barrier around compatible subsea cables.

Deep-Sea Cable Penetrators

Available in multiple formats, these penetrators provide waterproof cable entry points for high-pressure environments.

Low-Depth M10 Gland Cable Penetrators

A lightweight, lower-cost solution for shallow deployments, offering compression sealing up to 100 m depth.

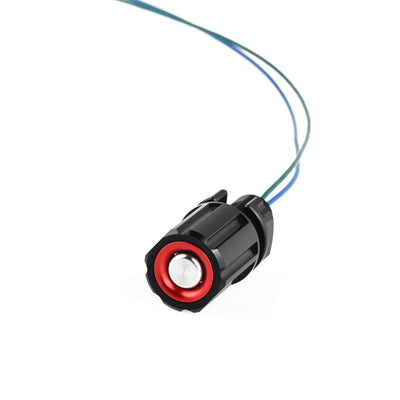

Deep-Sea Cable Connectors – M10 Bulkheads

Modular M10 bulkhead connectors designed for mating with male plugs, enabling signal and power transmission across watertight barriers.

These connectors are compatible with Blu-Sub lights, thrusters, cameras, and other systems—and also support third-party devices requiring power and communication.

Sold Separately

Metric Sealing Plug (Blank)

Used to seal unused M10 cable penetrator ports on the Subsea Watertight Enclosure Box, ensuring full watertight integrity. Available in M6, M8, M10, M14, and M16 thread sizes. Machined from corrosion-resistant aluminum and rated for depths up to 1,000 m / 3,281 ft.

Sold Separately

Blu-Sub offers two compatible solutions for managing pressure equalization, enclosure servicing, and vacuum leak testing. Each option supports different operational needs and levels of sealing performance:

Subsea M10 Self-Sealing Vent & Vacuum Plug

An advanced self-sealing port that allows both vacuum leak testing and retention of negative internal pressure after hose removal. The internal valve and lock cap maintain vacuum post-disconnection, making it ideal for preventing condensation or stabilizing pressure. Includes bulkhead, copper vacuum plug, and lock cap. Rated to 1,000 m / 3,280 ft. Applying negative pressure can also help hold the enclosure closed, improving seal performance during storage or deployment.

Subsea M8 Vent & Vacuum Plug

A compact two-part system for manual venting and temporary vacuum testing. Vacuum must be resealed manually by inserting the plug after test. Best for quick leak checks or venting during servicing. Rated to 1,000 m / 3,280 ft. Brief vacuum pressurization can assist with pulling flanges tight or holding enclosure lids shut prior to fastener installation. Note: this option requires drilling a dedicated M8 hole into the enclosure wall for installation.

| Specification | Watertight Box |

|---|---|

| Material | 6061 Aluminum |

| Appearance | Black Anodized |

| Screw Material | 304 Stainless Steel |

| Rated Depth | 300 m / 984 ft |

| Weight | 3508 g |

| Internal Dimension (L×W×H) | 202 × 132 × 79.5 mm |

| External Dimension (L×W×H) | 222 × 152 × 101.5 mm |

| Main Thickness | 10 mm |

| Penetrator Holes | 20× Thrus of 10.1 mm |

| External Mounting Hole | M4 |

| Internal Mounting Hole | M3 |

NOTE: Minor white residue or discoloration may appear on the surface due to the anodization process. This is purely cosmetic and does not affect the box’s waterproofing or sealing performance.

Can it still be used if the O-ring contact surface is scratched?

No. Scratches on the O-ring contact surface can compromise sealing integrity and may lead to leaks. The enclosure or pressure vessel (PV) should not be used if the sealing surface is damaged.

Does the O-ring need to be greased during installation?

Yes. Applying silicone grease to the O-ring is necessary to ensure smooth assembly and disassembly. Without lubrication, the lid may be very difficult to remove or seat properly in the underwater pressure housing.

What is the internal usable size?

The internal dimensions are approximately 202 × 132 × 79.5 mm. Note that the corners on the sides and bottom are rounded, which may affect the fit of square components within the engineered pressure vessel enclosure.

Will the enclosure rust over time?

The aluminum housing is anodized for basic corrosion resistance, but it may still corrode over time in submerged or saltwater environments. For extended underwater use, consider adding sacrificial anodes for additional protection of the engineered pressure vessel PV.

Is the number of penetrator holes fixed?

Yes. The enclosure has a fixed number of penetrator ports. Any unused holes can be sealed with Cable Penetrator Blanks. If additional holes are needed, they may be manually drilled—however, too many penetrations may reduce the enclosure's pressure resistance and compromise the watertight integrity of the underwater pressure housing.

How do I open the lid safely?

Use a plastic pry tool or other non-marring implements to lift the lid gently, starting from a corner and working around the perimeter. Avoid metal tools that may scratch the surface of the pressure vessel enclosure.