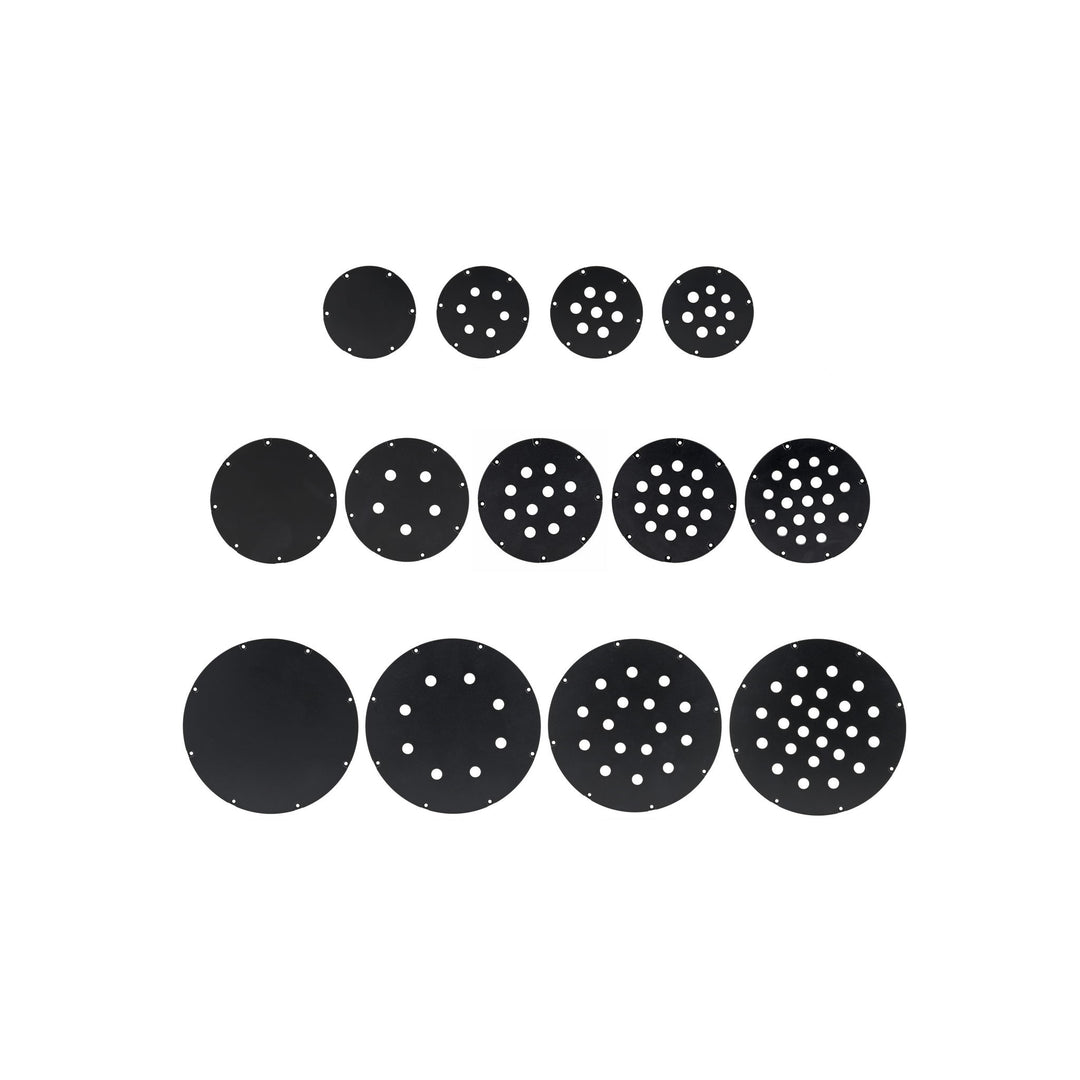

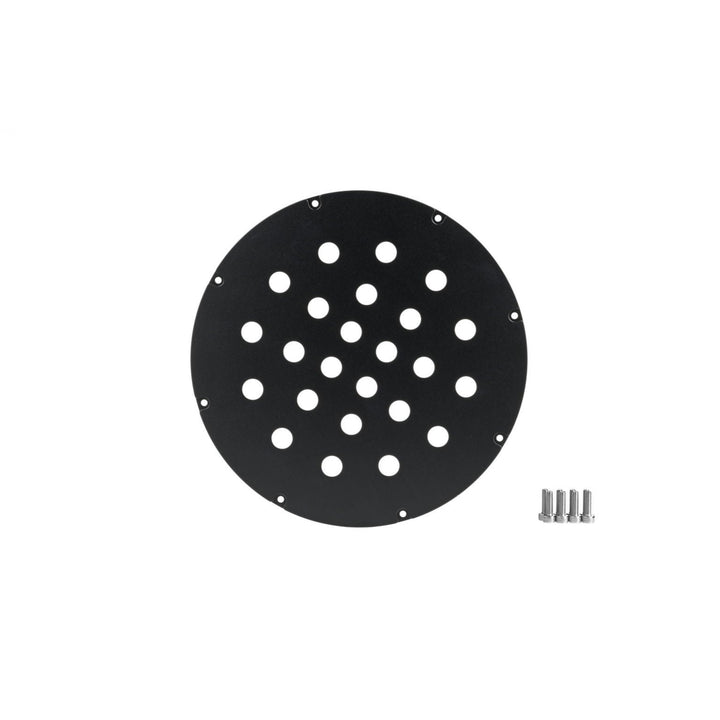

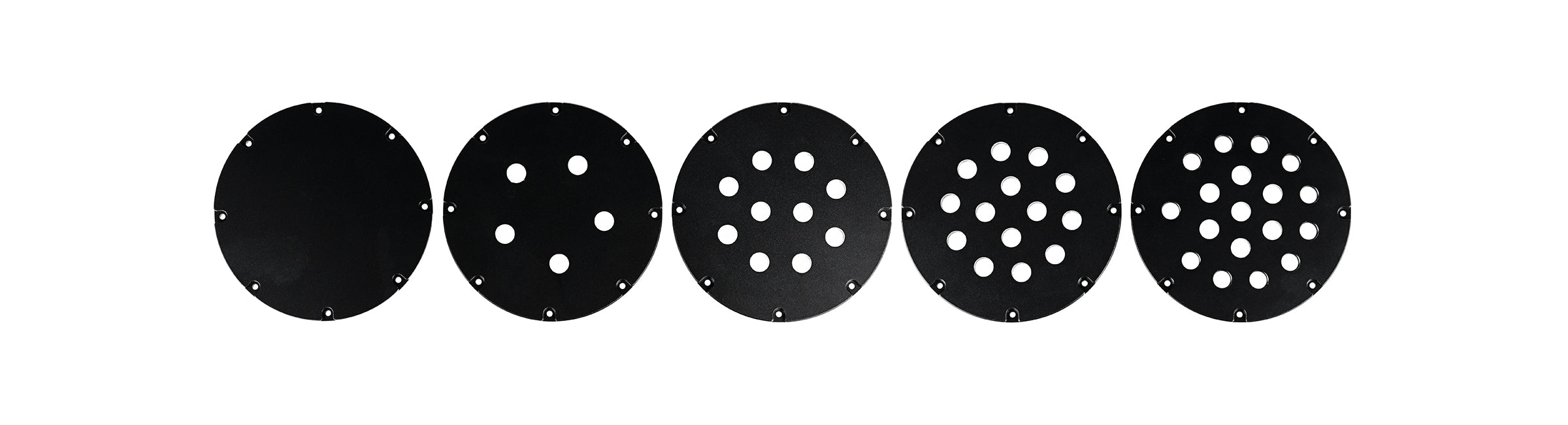

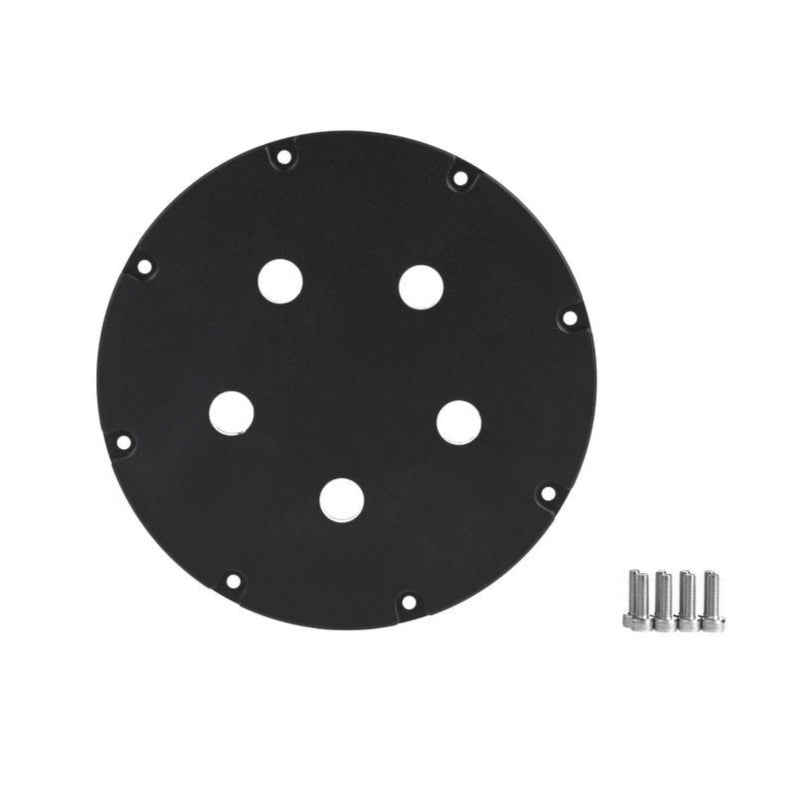

Each Blu-Sub End Cap is offered in two ways: precision-machined standard hole patterns, and fully custom layouts drilled to order. All standard configurations are CNC-machined prior to anodizing, ensuring a complete, uniform black finish. Custom hole layouts are drilled after anodizing and are tailored exactly to your DXF design.

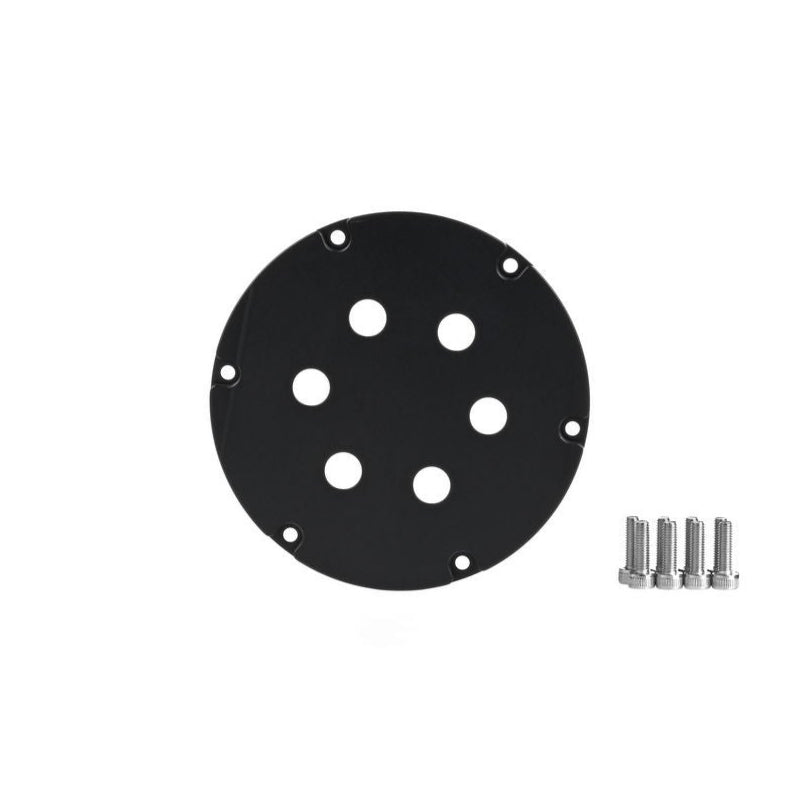

All custom layouts and all standard variants use precision-drilled thru holes, with one exception: the 115 mm 18-Hole model, which includes 11× M10 threaded holes plus 7× M10 thru holes. Custom threaded-hole layouts are not available; all custom designs are produced with thru holes only.

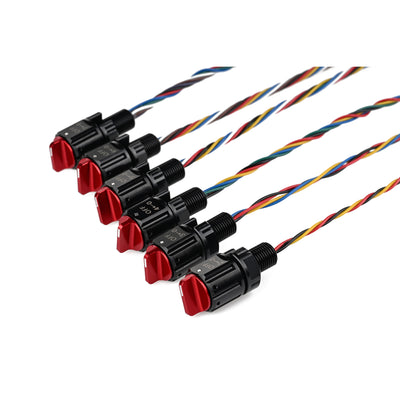

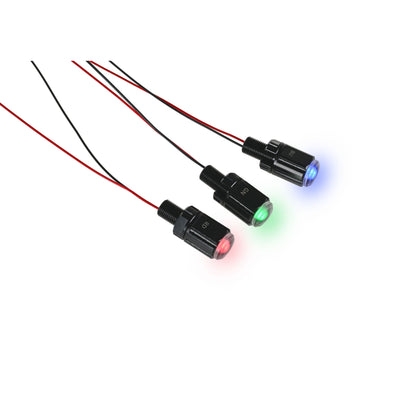

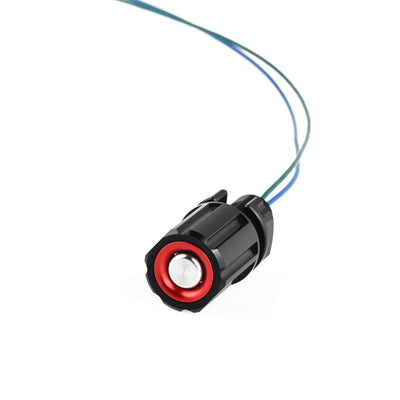

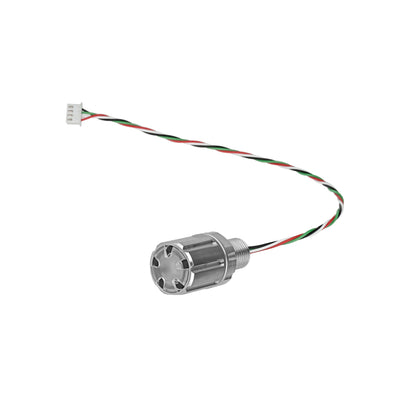

Threaded holes allow penetrator devices to be mounted without a rear nut (useful on dense layouts like the 18-hole configuration). Thru-hole variants require a rear nut, so ensure adequate clearance based on your component selection.

For custom layouts only: custom holes are drilled after anodizing, so the inner surfaces of those drilled holes will show exposed aluminum. This affects custom-drilled holes only and does not apply to standard CNC-machined layouts. The exposed aluminum has no effect on sealing performance and is never visible once penetrators, plugs, or fittings are installed.

For full instructions, see the Step-by-Step Guide to Customizing an End Cap.

Guidelines for Custom End Cap Design

Custom Order Process

- Purchase the correct end cap size: Add the appropriate size to your cart (Custom 85 mm, 115 mm, or 165 mm) and complete checkout.

- Download the DXF file: Use the link in the Downloads section below to get the correct 2D CAD template for your selected size.

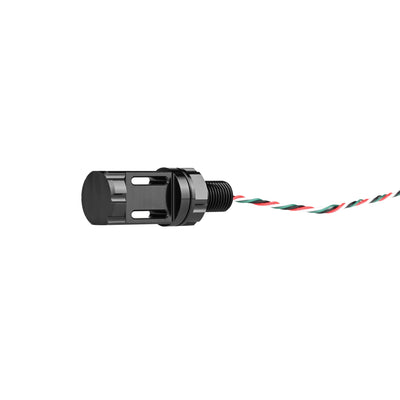

- Edit the DXF: Open the file in CAD software (e.g., AutoCAD, Fusion 360). Use circles to mark hole positions. Supported thru-hole diameters are M6 (6.1 mm), M8 (8.1 mm), M10 (10.1 mm), M14 (14.1 mm), M16 (16.1 mm). Contact us if you need a different size.

- Submit your design: Email your edited DXF file to contact@blu-sub.com, including your order number and the quantity required. Allow 2 additional business days for processing.

DIY Customization (Blank End Caps)

As an alternative, you may drill your own holes using blank end caps (listed as “End Cap Blank – no holes”). Use a drill press or guided equipment to ensure perpendicular, watertight holes. Test your layout in advance with the actual components or penetrators you plan to install.

For detailed instructions, refer to the Step-by-Step Guide to Customizing an End Cap.

Important Warnings

- Do not scratch the O-ring contact surface: Any damage can result in leaks or seal failure. Discontinue use if the sealing surface is compromised.

- Rear nut clearance: For thru-hole variants, penetrators secured with nuts must not extend beyond the circular sunken step on the back of the end cap. Reference the Surface of Subsidence (B) dimension in the Technical Specifications table.

- Depth rating disclaimer: Custom or user-drilled end caps are made to your specifications. Blu-Sub does not guarantee pressure ratings for modified units. Use at your own risk — we are not liable for leaks or failure due to incorrect drilling, sealing, or design.

Sold Separately

A Subsea Aluminum Flange is required when using either Blu-Sub Aluminum Tubes or Acrylic Tubes. The flange creates a rigid interface that enables secure fastening of end caps to the tube body while ensuring proper compression of the O-rings for a watertight seal.

It also serves as the structural mounting base for the end cap, aligning components precisely and helping to distribute pressure evenly under deep-sea conditions.

Flanges are matched to the diameter of the tube—available in 85 mm, 115 mm, or 165 mm sizes—and must be installed using compatible screws and sealing methods to ensure enclosure integrity in subsea environments.

Sold Separately

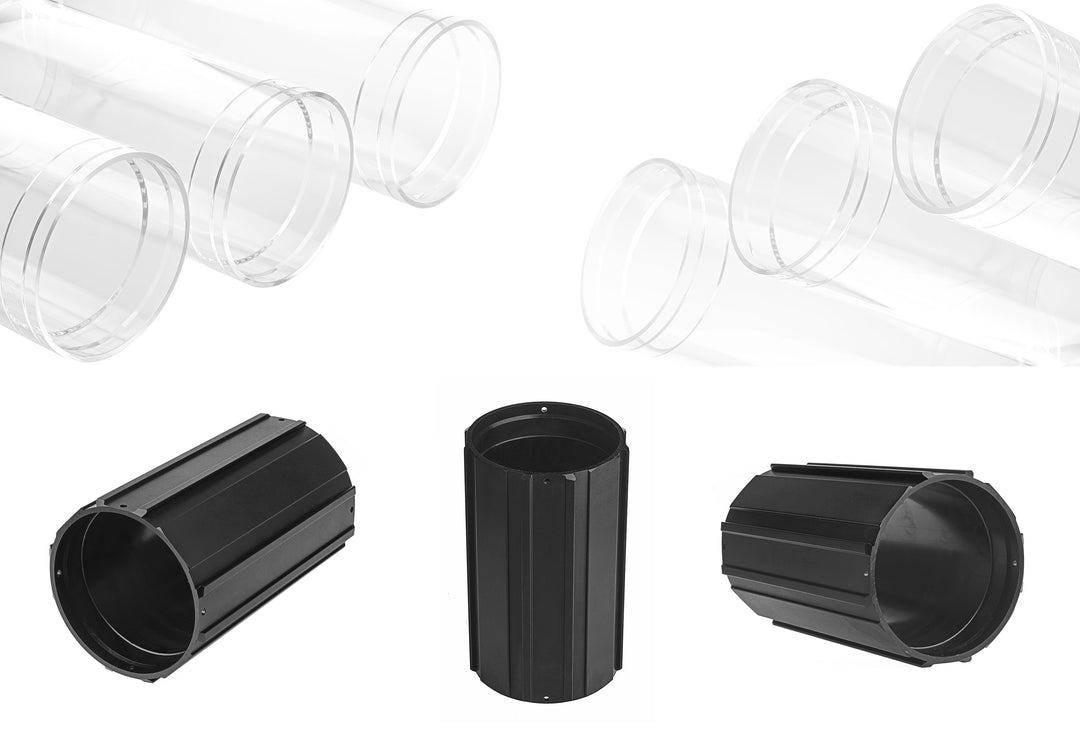

Compatible with Subsea Enclosure Acrylic Tubes

Lightweight, optically clear tube ideal for vision-enabled subsea systems. The Blu-Sub Aluminum End Cap mounts securely using a flange, creating a watertight seal. Compatible with tray sets for organizing internal electronics.

Compatible with Subsea Enclosure Aluminum Tubes

Rugged 115 mm pressure-rated housing for deep-sea use. The Blu-Sub Aluminum End Cap mates via flange to provide a durable seal rated to 1,000 m / 3,281 ft. Tray sets fit securely inside for thermal and structural support.

Sold Separately

Subsea Polymer Flange & End-Cap 115 mm: Lightweight and cost-effective option for shallow water use. Suitable for general-purpose enclosures up to 30 m / 98 ft depth.

Subsea Optical Dome Flange & End-Cap 115 mm: Wide-angle acrylic dome for camera and vision-based ROV systems. Requires the Subsea Aluminum Flange for mounting. Depth rated to 1,000 m / 3,281 ft.

Subsea Optical Glass Flange & End-Cap 115 mm: High-clarity flat glass window for optical sensors and imaging payloads. Offers superior pressure resistance compared to acrylic. Depth rated to 300 m / 984 ft.

Acrylic vs. Aluminum End Caps

Aluminum End-Cap

Better suited for deeper subsea use and longer-duration pressure exposure, and more tolerant of frequent assembly/disassembly. Some aluminum end-cap variants offer threaded-hole options. Opaque design when internal visibility is not required.

Alternative Option: Acrylic End Cap

CNC-machined from transparent acrylic and polished for exceptional optical clarity. Intended for shallow-water, short-term use and infrequent assembly/disassembly—do not overtighten fasteners. All variants are thru-hole only (no threaded options). Acrylic must not contact alcohol, solvents, harsh cleaners, or thread locker; clean only with water or acrylic-safe cleaners.

| Item | Material | Weight |

|---|---|---|

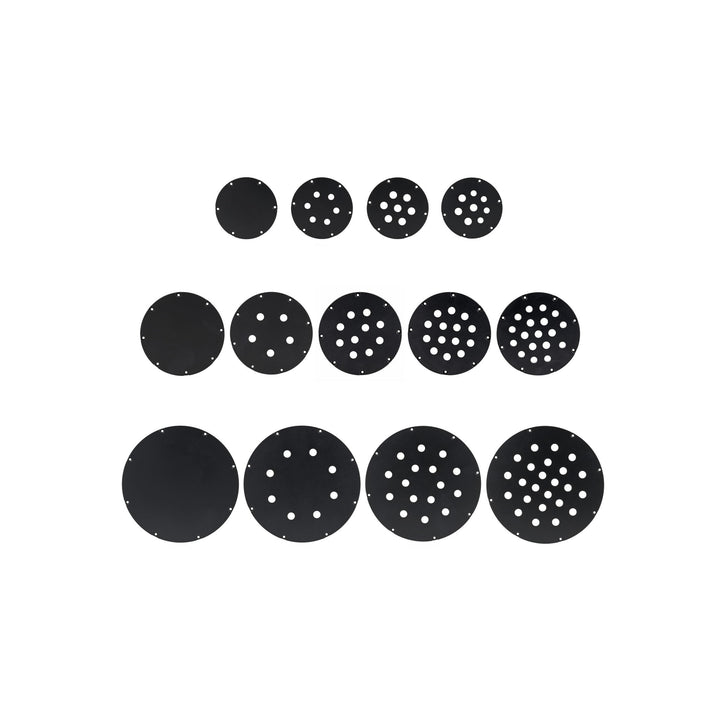

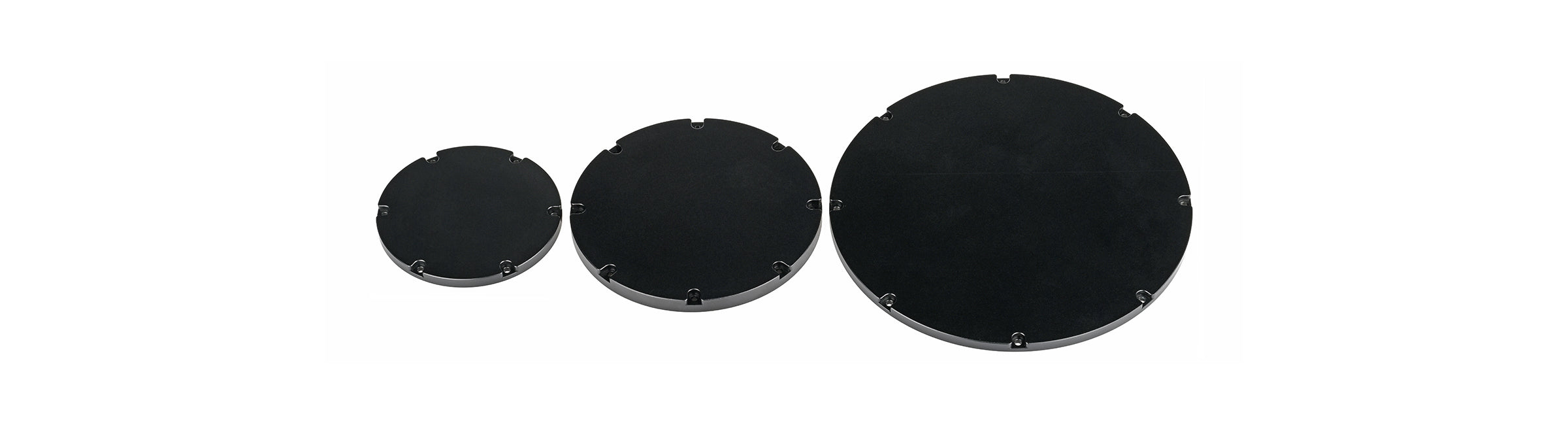

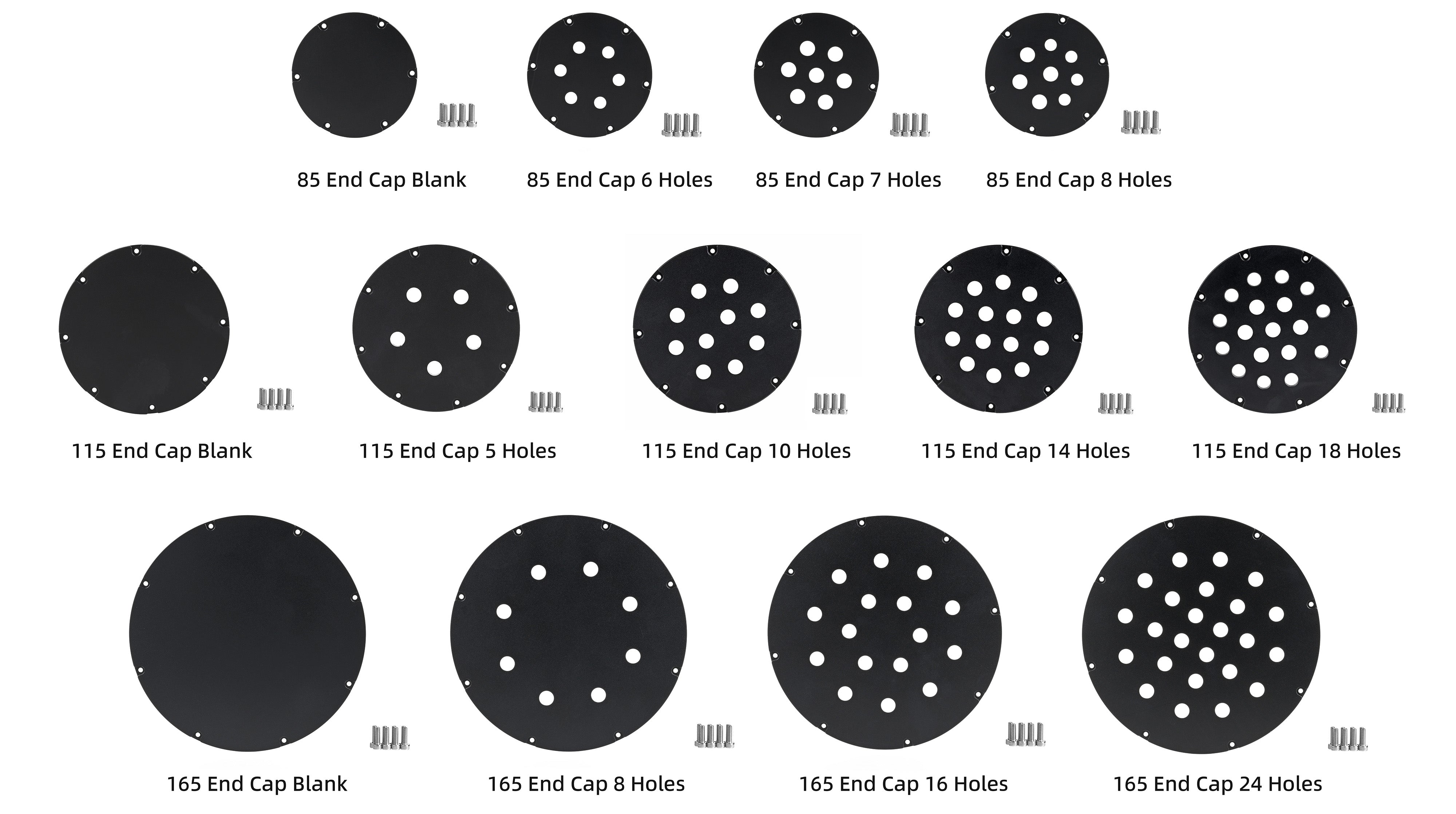

| 85 End Cap Blank (no holes) | Black Anodized Aluminum | 89g |

| 85 End Cap 6 Holes (6×8.1 Thru) | Black Anodized Aluminum | 83g |

| 85 End Cap 7 Holes (7×10.1 Thru) | Black Anodized Aluminum | 79g |

| 85 End Cap 8 Holes (4×8.1 Thru + 4×10.1 Thru) | Black Anodized Aluminum | 80g |

| 115 End Cap Blank (no holes) | Black Anodized Aluminum | 226g |

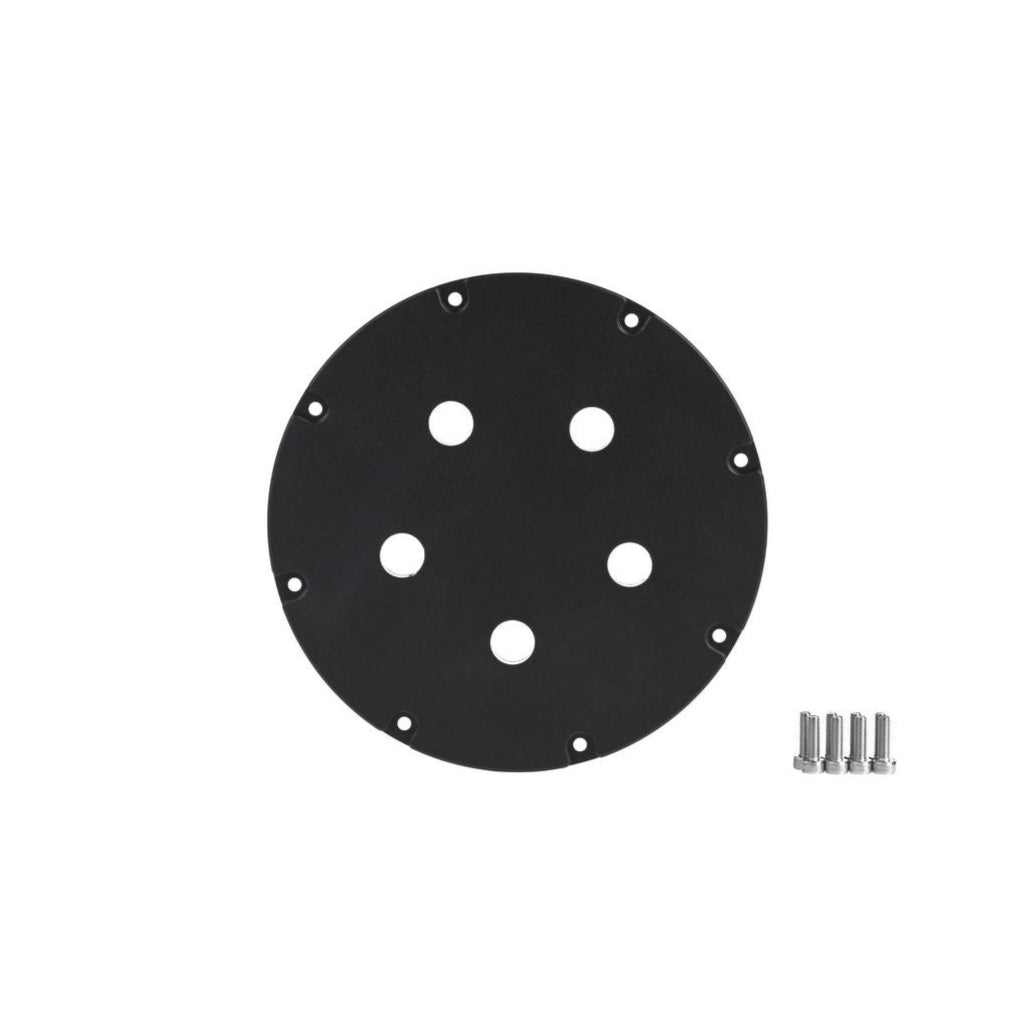

| 115 End Cap 5 Holes (5×10.1 Thru) | Black Anodized Aluminum | 214g |

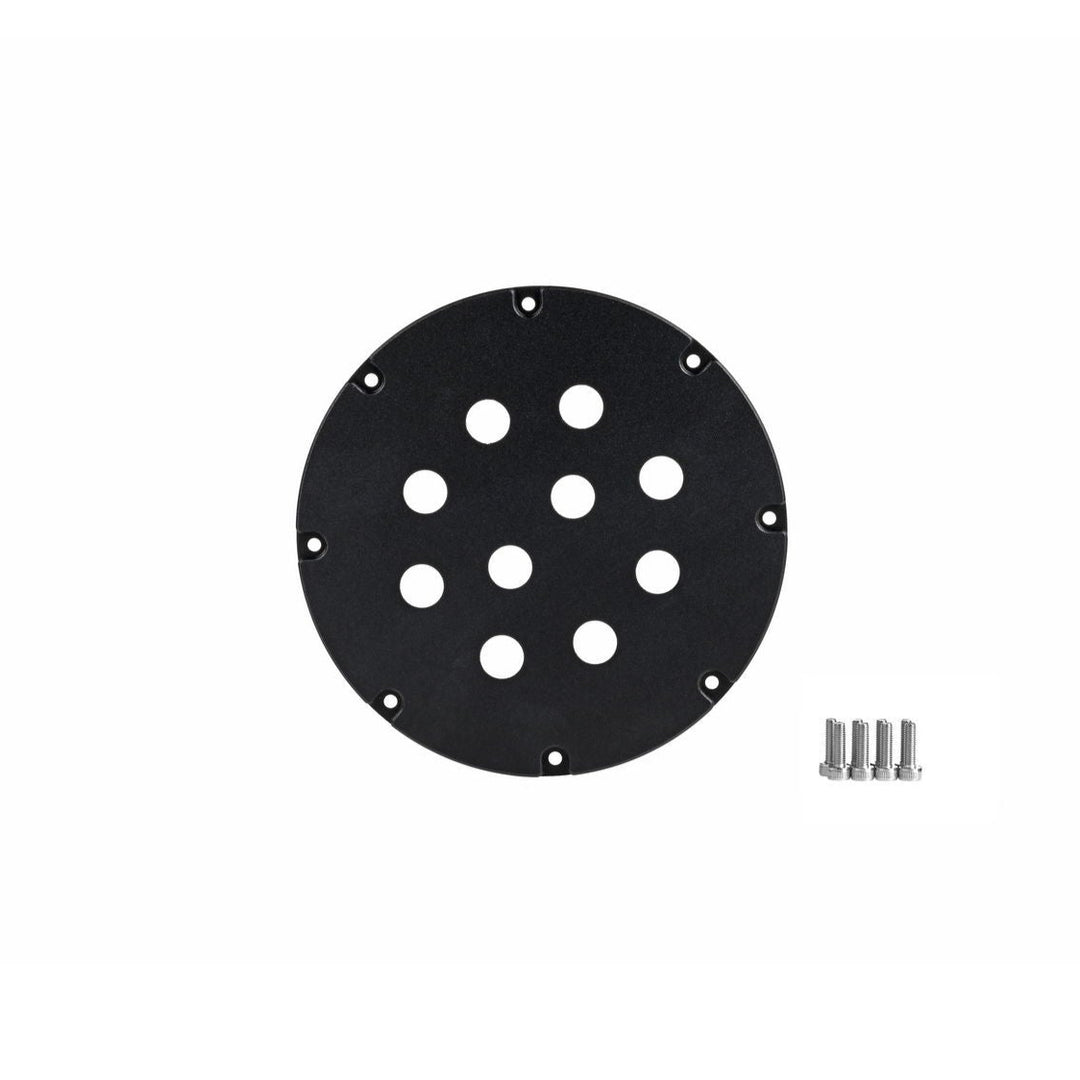

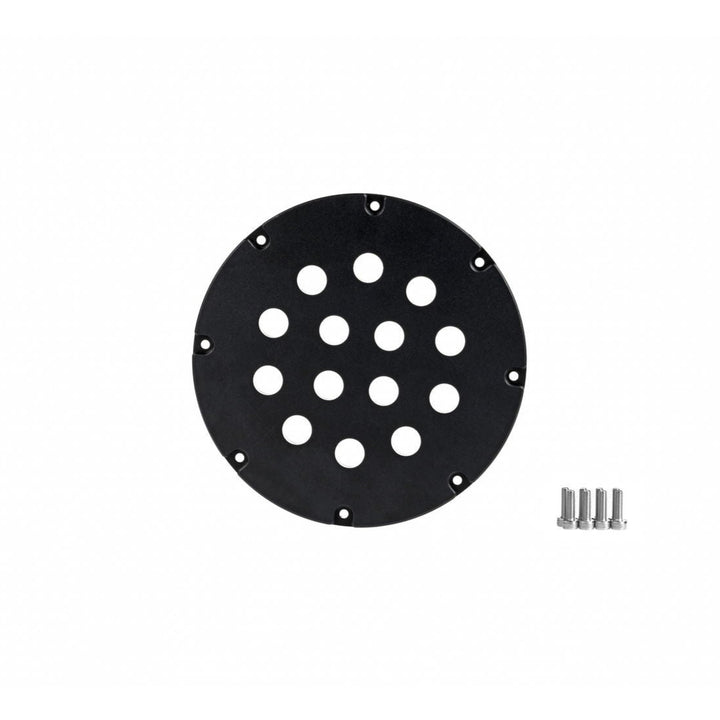

| 115 End Cap 10 Holes (10×10.1 Thru) | Black Anodized Aluminum | 207g |

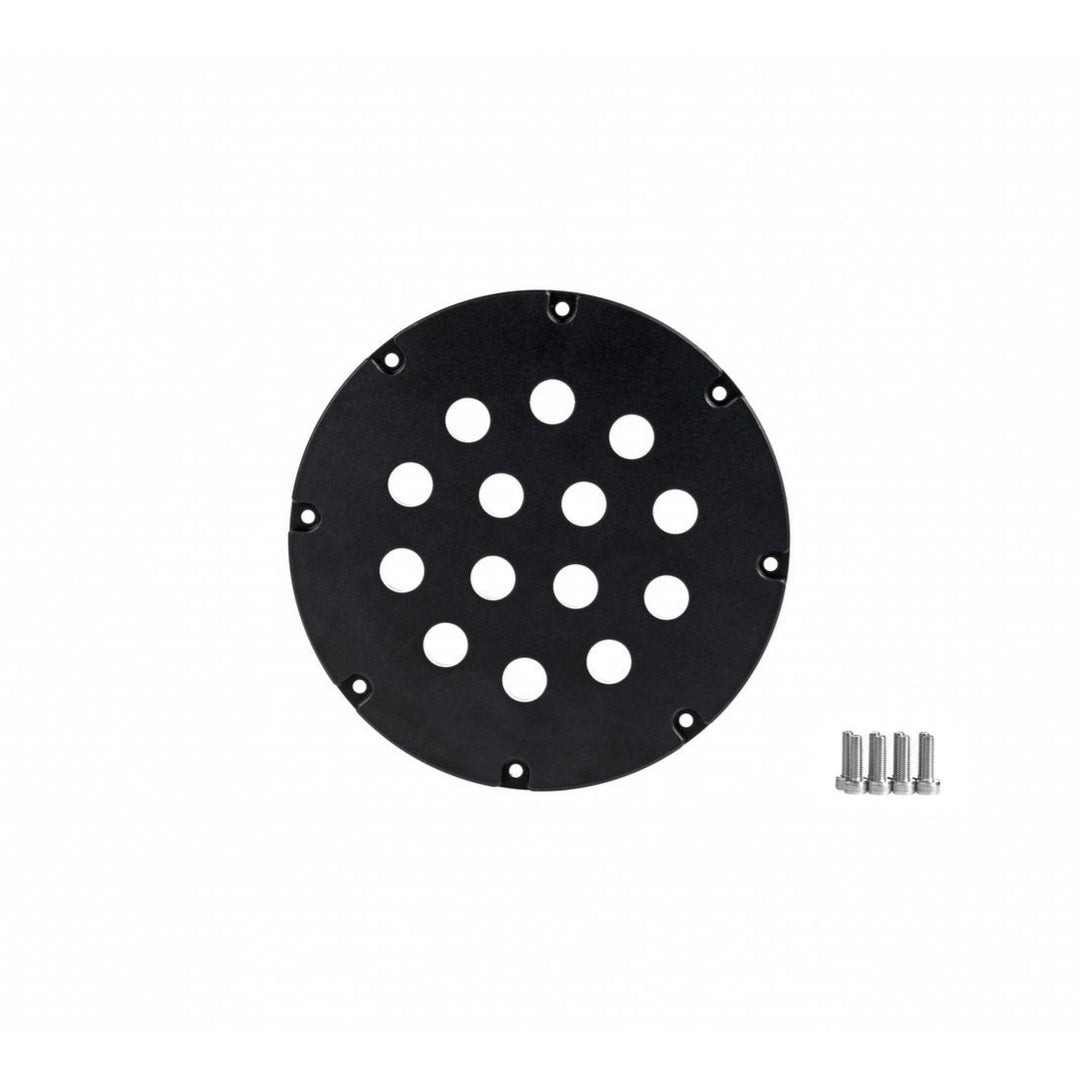

| 115 End Cap 14 Holes (14×10.1 Thru) | Black Anodized Aluminum | 200g |

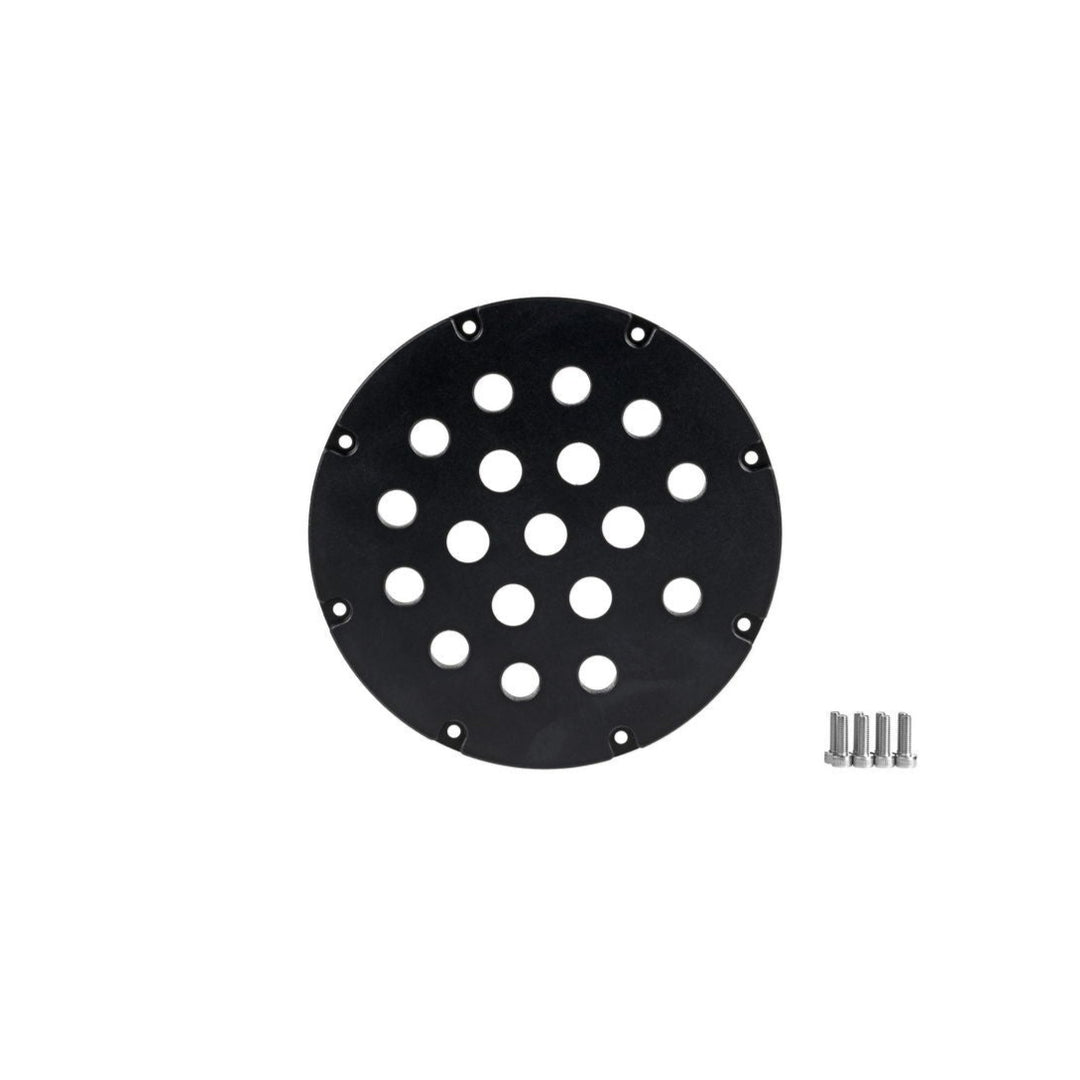

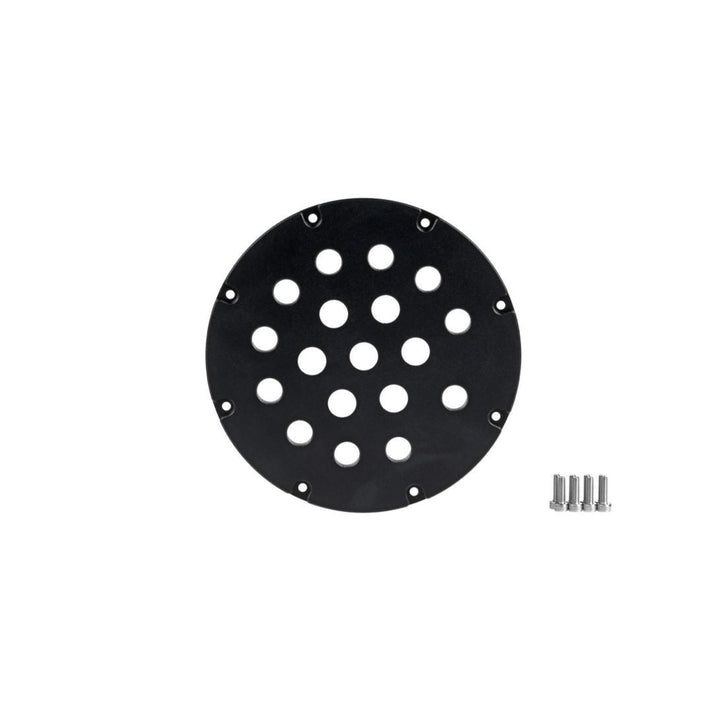

| 115 End Cap 18 Holes (11×10.1 Threaded + 7×10.1 Thru) | Black Anodized Aluminum | 194g |

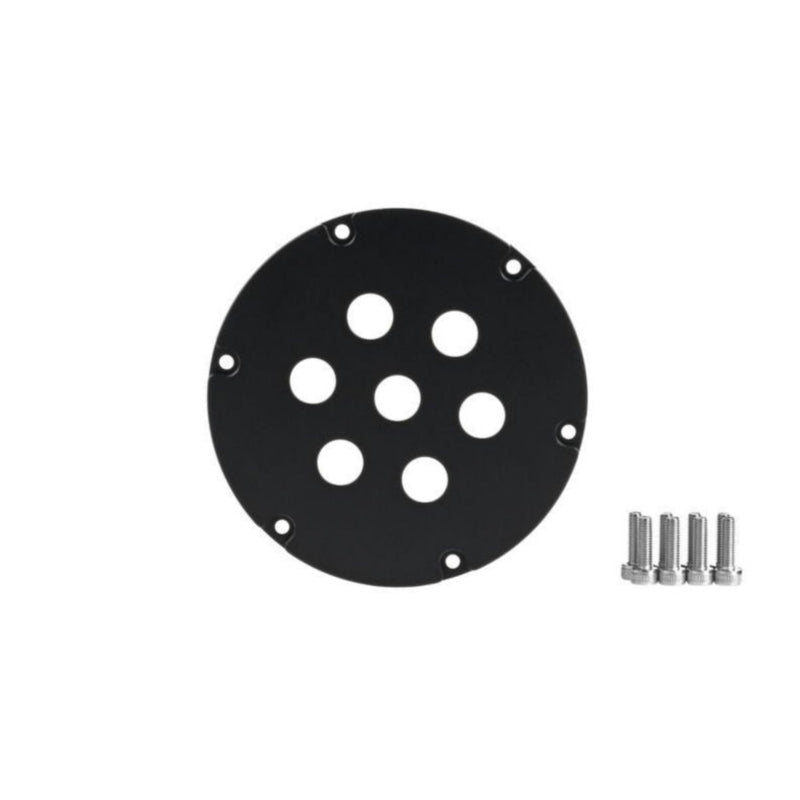

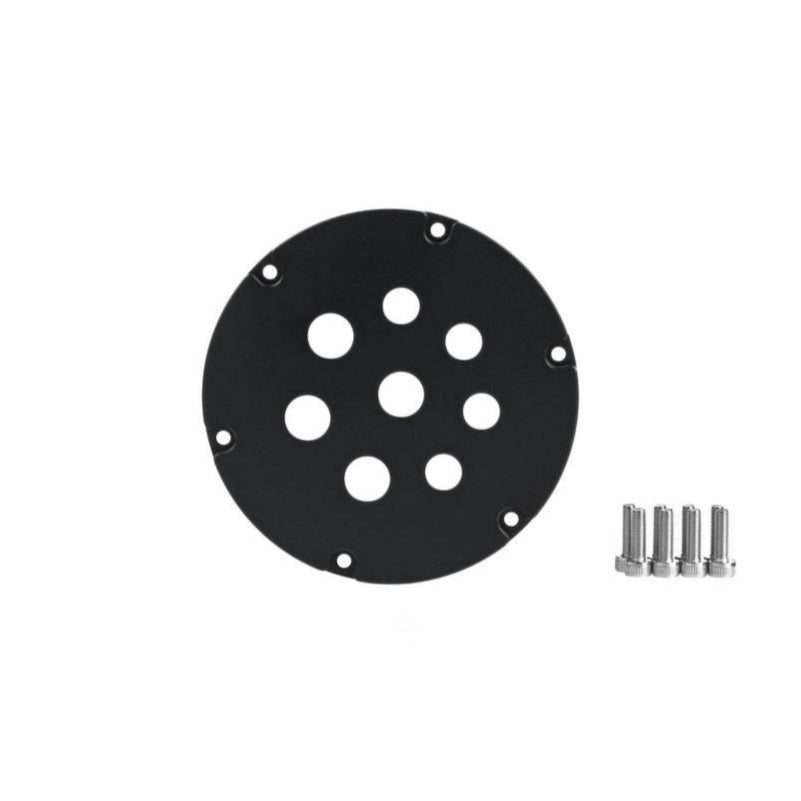

| 165 End Cap Blank (no holes) | Black Anodized Aluminum | 340g |

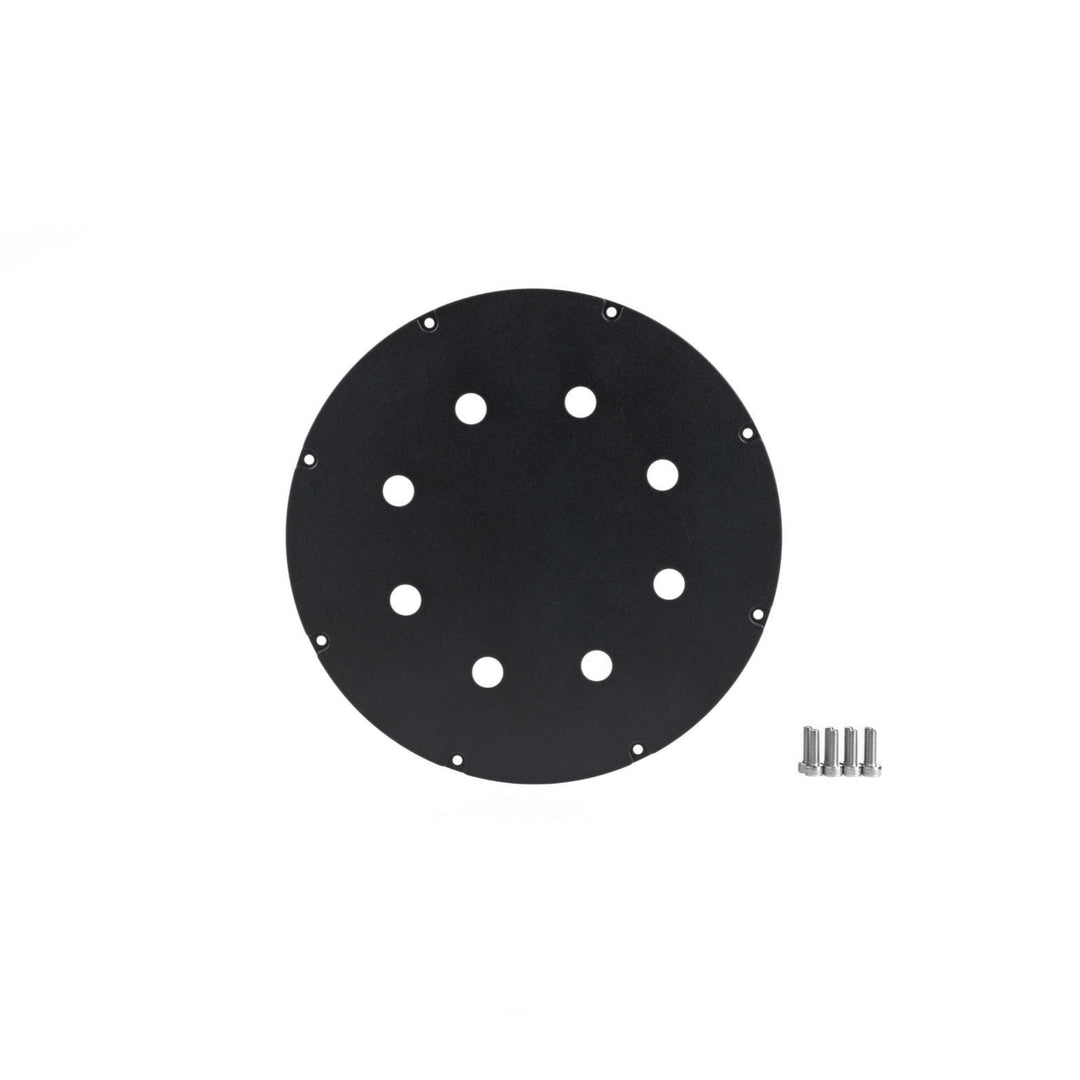

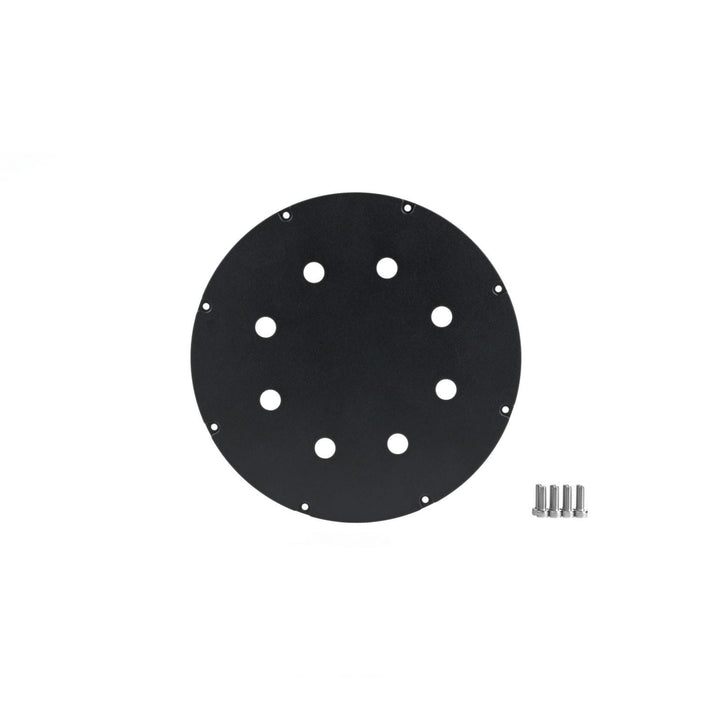

| 165 End Cap 8 Holes (8×10.1 Thru) | Black Anodized Aluminum | 327g |

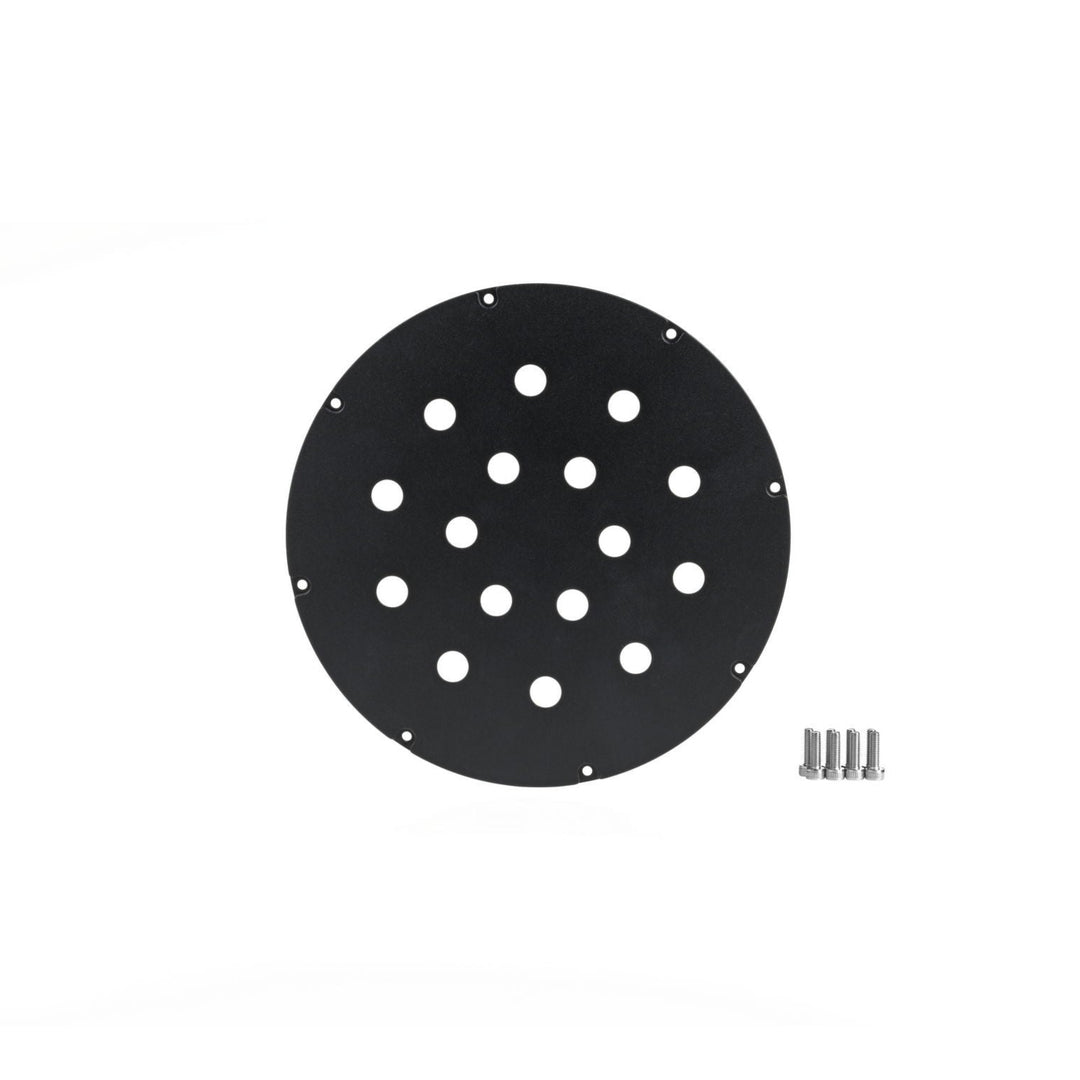

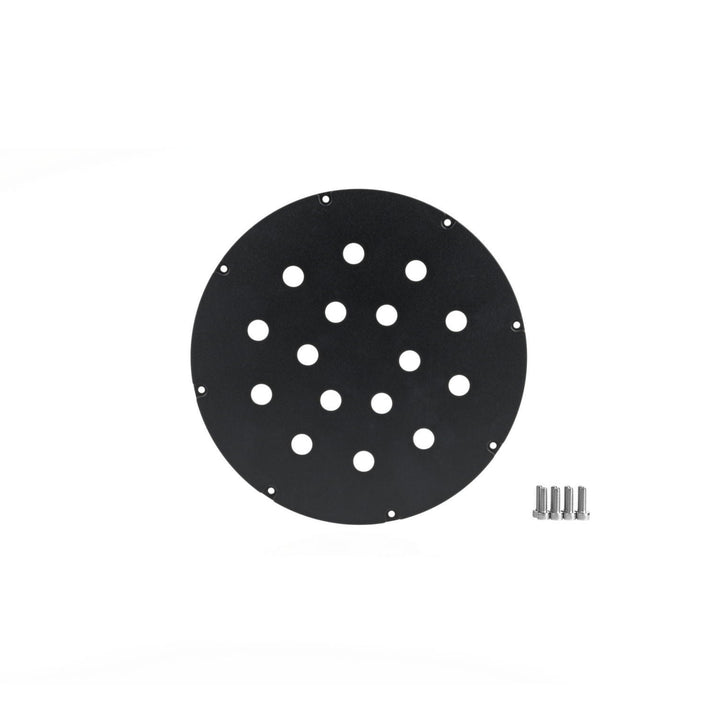

| 165 End Cap 16 Holes (16×10.1 Thru) | Black Anodized Aluminum | 316g |

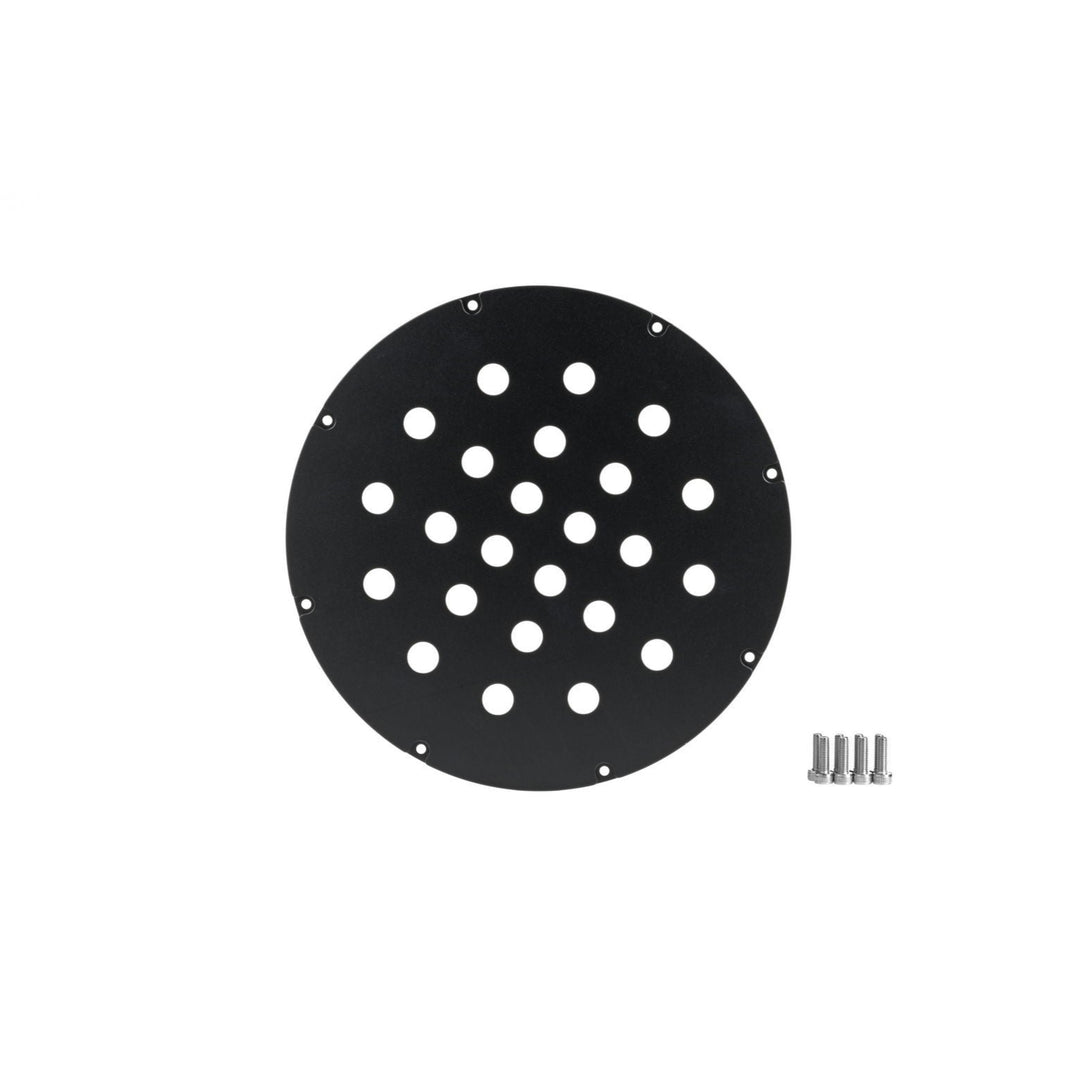

| 165 End Cap 24 Holes (24×10.1 Thru) | Black Anodized Aluminum | 309g |

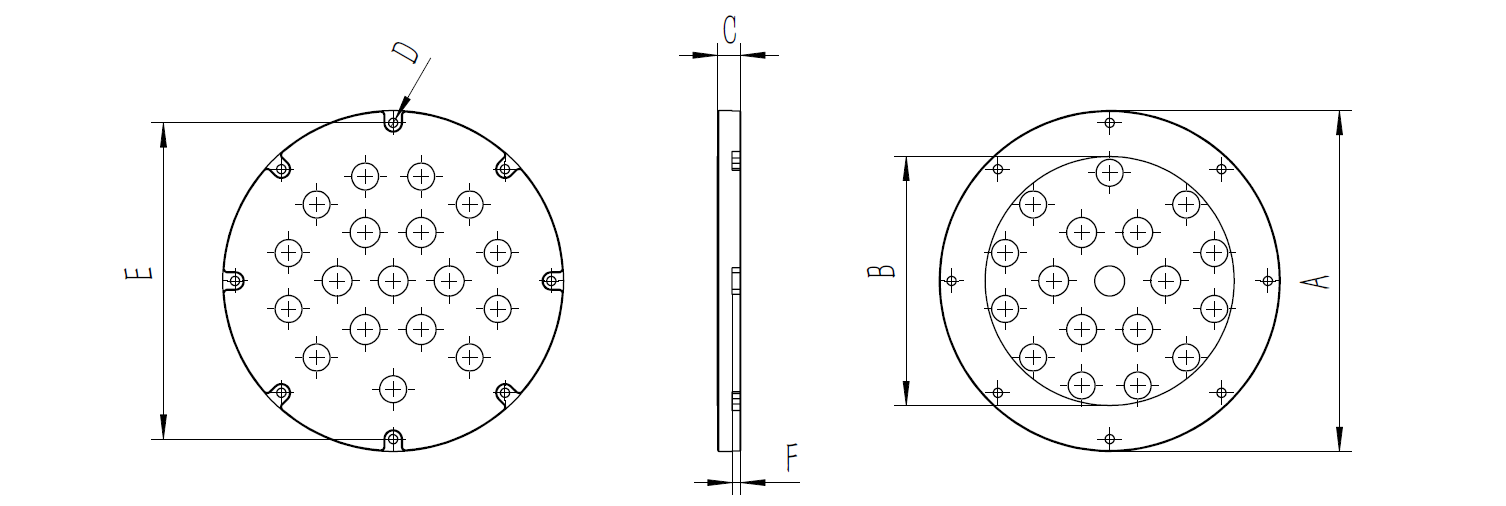

| Size | Outer Diameter (A) | Surface of Subsidence (B) | Thickness (C) | Mounting Holes (D) | Screw Hole Circle (E) | Mounting Hole Subsidence (F) |

|---|---|---|---|---|---|---|

| 85 mm | 85 mm | 58 mm | 6 mm | 6×Ø3.1 mm | 78 mm | 3 mm |

| 115 mm | 115 mm | 84 mm | 8 mm | 8×Ø3.1 mm | 106.7 mm | 3 mm |

| 165 mm | 165 mm | 136 mm | 6 mm | 8×Ø3.1 mm | 158 mm | 3 mm |

Note: Only the 115 mm 18-Hole variant includes threaded holes (11× M10 threaded + 7× M10 thru). All other end-cap variants are thru-hole only.

Can it still be used if the contact surface of the O-ring is accidentally scratched?

No, it cannot be used, as there is a risk of leakage.

Are they compatible with Blu-Sub aluminum tubes, acrylic tubes, and flanges?

Yes, they are compatible with tubes of the same size and can be directly replaced.

Is it a defective product if there are a few lines on the surface?

No, a few lines are not scratches — they are marks left by the tool during processing. They can be used normally without affecting the sealing.

Whether to apply grease to O-rings every time?

Yes, applying lubricating grease has several benefits: it helps remove dust and impurities from O-rings during application and allows O-rings to adhere to the groove for easy assembly.

What if I want to use acrylic with perforations for the end cap despite the recommendation?

You can download the DXF-format contour diagram of the end cap, draw the perforations yourself, and then have the acrylic sheet laser-cut at a local shop or find a service that offers laser cutting.

Why is there no M14 or M16 hole for the 165 end cap?

Due to the large number of holes and sizes, it is not possible to provide all the holes in stock. However, you can use actual threading screws or a printed drilling template to compare. Some of the M10 holes can be reamed out to M14 or M16. When reaming or drilling with a non-porous hatch, there is no need to oxidize the surface again after drilling, as the hole will not come into contact with water and can be used directly after opening.

Can I use acrylic as a threaded or window end cap?

Transparent acrylic end caps are not available and are not recommended for use as threaded or window components. Testing has shown that acrylic sheets have inconsistent pressure resistance and are prone to cracking around mounting holes. If a transparent window is required, consider using the Glass Window Flange instead. However, for low-pressure applications, you may download the outer contour drawings and have an acrylic sheet laser-cut by a local shop or advertising business.

Do you offer threaded-hole end caps?

Yes. Only the 115 mm 18-Hole version includes threaded holes (11× M10 threaded + 7× M10 thru). All other end-cap variants are thru-hole only.

Do blank aluminum end caps include adhesive hole-marking stickers?

No. Blank aluminum end caps do not include stickers. Adhesive hole-marking stickers are only provided with the Subsea Polymer Flange & End-Cap.