Cable Penetrators & Gland Cable Penetrators Compatibility Guide:

| Item | Deep-Sea Cable Penetrators | Deep-Sea M10 Gland Cable Penetrators | Low-Depth M10 Gland Cable Penetrators | Mid-Depth M8 Gland Cable Penetrators |

|---|---|---|---|---|

|

3-Core (16AWG) Underwater Cable BS-SSC-3CORE-BLK-16A1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

7.8 × 5.6 Stainless Steel BS-SSC-GLPEN-SSX-78A1 7.8 × 5.6 Aluminum BS-SSC-GLPEN-ALU-78A1 |

7.8 × 5.6 Copper BS-SSC-GLPEN-NPB-BRA1 |

Not Compatible |

|

6-Core (24AWG) Underwater Cable BS-SSC-6CORE-BLK-24A1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-08A1 |

7.2 × 4.6 Stainless Steel BS-SSC-GLPEN-SSX-72A1 7.2 × 4.6 Aluminum BS-SSC-GLPEN-ALU-72A1 |

7.2 × 4.6 Copper BS-SSC-GLPEN-NPB-BRA2 |

Not Compatible |

|

4-Core (28AWG) Underwater Cable BS-SSC-4CORE-BLK-28A1 |

M6x1 Aluminum BS-SSC-CBLPN-BLK-06A1 |

5.6 × 3.4 Stainless Steel BS-SSC-GLPEN-SSX-56A1 5.6 × 3.4 Aluminum BS-SSC-GLPEN-ALU-56A1 |

5.6 × 3.4 Copper BS-SSC-GLPEN-NPB-BLA1 |

Not Compatible |

|

6-Core (2x 16AWG / 4x 26AWG) Underwater Cable BS-SSC-6CORE-BLK-MXA1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

8.4 × 5.9 Stainless Steel BS-SSC-GLPEN-SSX-84A1 8.4 × 5.9 Aluminum BS-SSC-GLPEN-ALU-84A1 |

8.4 × 5.9 Copper BS-SSC-GLPEN-NPB-BRA3 |

Not Compatible |

|

4-Core (2x 24AWG / 2x 26AWG) Underwater Cable BS-SSC-4CORE-BLK-MXA1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

7.8 x 4.1 Stainless Steel BS-SSC-GLPEN-SSX-78A2 7.8 x 4.1 Aluminum BS-SSC-GLPEN-ALU-78A2 |

7.8 x 4.1 Copper BS-SSC-GLPEN-NPB-BRA4 |

Not Compatible |

|

3-Core (20AWG) Underwater Cable BS-SSC-3CORE-BLK-20A1 |

M8x1 Aluminum BS-SSC-CBLPN-BLK-08A1 |

6.4 × 4.3 Stainless Steel BS-SSC-GLPEN-SSX-64A1 6.4 × 4.3 Aluminum BS-SSC-GLPEN-ALU-64A1 |

6.4 × 4.3 Copper BS-SSC-GLPEN-NPB-BLA2 |

M8 Aluminum BS-SSC-THGLP-ALU-08A1 |

Sold Separately

Blu-Sub offers four types of cable penetrators designed to work with its subsea power and communication cables, each suited for different underwater applications:

Deep-Sea Cable Penetrators – Standard body design for high-pressure, full-depth deployments. Depth Rating: Up to 1,000 m / 3,281 ft

Deep-Sea M10 Gland Cable Penetrators – Threaded M10 penetrators with compression glands for added strain relief and modular housing use. Depth Rating: Up to 1,000 m / 3,281 ft

Low-Depth M10 Gland Cable Penetrators – Compact and cost-effective option for shallow water or low-pressure systems. Depth Rating: Up to 100 m / 328 ft

Mid-Depth M8 Gland Cable Penetrators – Slim-profile solution for small enclosures or tight mounting areas. Depth Rating: Up to 300 m / 984 ft

A compatibility guide is provided above to help you choose the correct model based on your cable and sealing needs.

Sold Separately

Deep-Sea Cable Connectors – Female Socket & Male Plug

Modular in-line connectors designed to terminate underwater cables with sealed male or female plug ends. These connectors allow the Deep-Sea Underwater Cable to form reliable, removable connections between subsea devices.

Deep-Sea Cable Connectors – M10 Bulkhead

Panel-mount connector that allows the cable to interface directly with enclosures or end-caps. Requires a matching male plug from the Deep-Sea Cable Connectors line to complete a watertight connection.

Deep-Sea Cable Connectors – Dummy Sealing Cap

Used to seal and protect unused connector ends when not in operation. Prevents moisture ingress and maintains system waterproofing in storage, transit, or standby conditions.

Sold Separately

This cable is fully compatible with the Subsea M10 Coupling Tube, which allows two lengths of cable to be joined securely using penetrators and potting compound, or enables repositioning of penetrator-mounted components such as lights, switches, or sensors to more accessible locations.

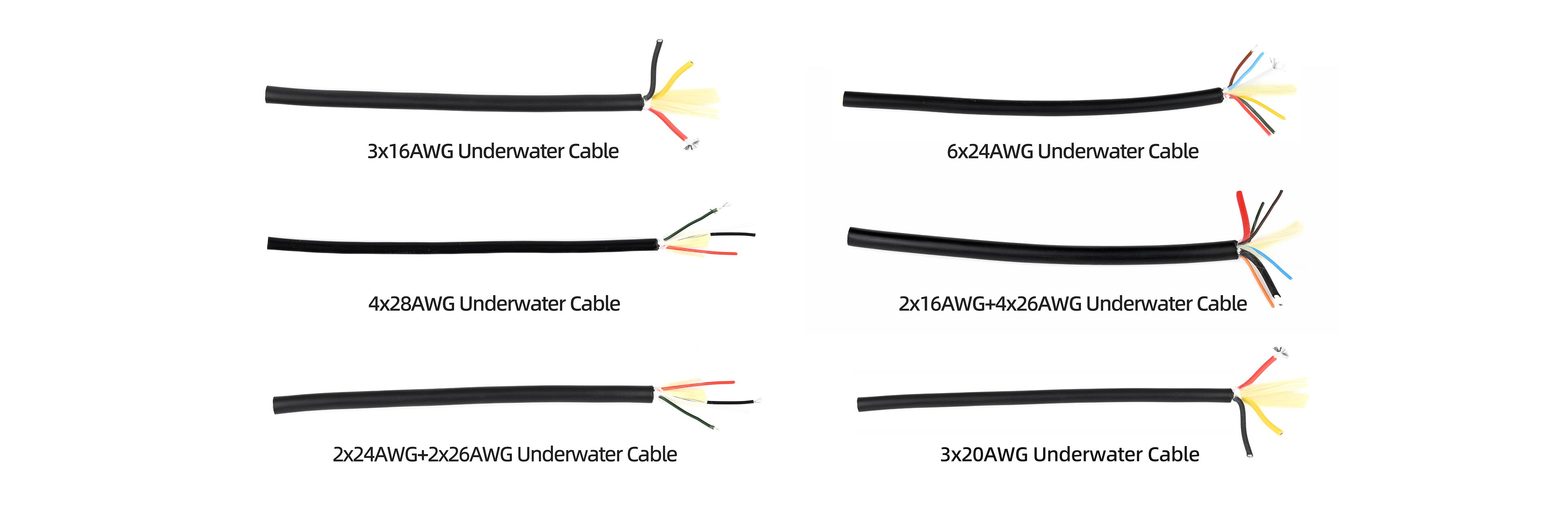

| Specification | 3-Core (16AWG) | 6-Core (24AWG) | 4-Core (28AWG) | 6-Core (2x 16AWG / 4x 26AWG) | 4-Core (2x 24AWG / 2x 26AWG) | 3-Core (20AWG) |

|---|---|---|---|---|---|---|

| Conductor | Tinned Copper Wire 169×0.10 | Tinned Copper Wire 19×0.127 | Tinned Copper Wire 13×0.10 | Tinned Copper Wire 104×0.127; 19×0.1 | Tinned Copper Wire 19×0.127; 19×0.1 | Tinned Copper Wire 119×0.08 |

| Insulation | Double-Layer PUR | |||||

| Insulated Wire Diameter (mm) | 2.4±0.1 | 1.4±0.1 | 1.2±0.1 | 2.8±0.1; 1.2±0.1 | 1.6±0.1; 1.4±0.1 | 1.8±0.1 |

| Filler | Kevlar, Non-Woven | |||||

| Jacket Material | Polyether PUR | |||||

| Jacket Thickness (mm) | 1.15 | 1.4 | 1.0 | 1.1 | 1.3 | 1.0 |

| Jacket Color | Black | |||||

| Conductor DC Resistance | ≤13.8Ω/km | ≤75Ω/km | ≤185Ω/km | <13.7Ω/km; <122Ω/km | ≤75Ω/km | ≤32Ω/km |

| Test Voltages | 1000V/min(AC) | 1000V/min(AC) | 700V/min(AC) | 1000V/min(AC) | 1000V/min(AC) | 1000V/min(AC) |

| Insulation Resistance (20°C) | ≥20MΩ·km | ≥20MΩ·km | ≥20MΩ·km | ≥20MΩ·km | >10MΩ·km | ≥20MΩ·km |

| Rated Voltage | Power Line 300V | |||||

| Minimum Bending Radius (Fixed) | 4D (D = Cable Diameter) | |||||

| Minimum Bending Radius (Occasional Movement) | 7.5D (D = Cable Diameter) | |||||

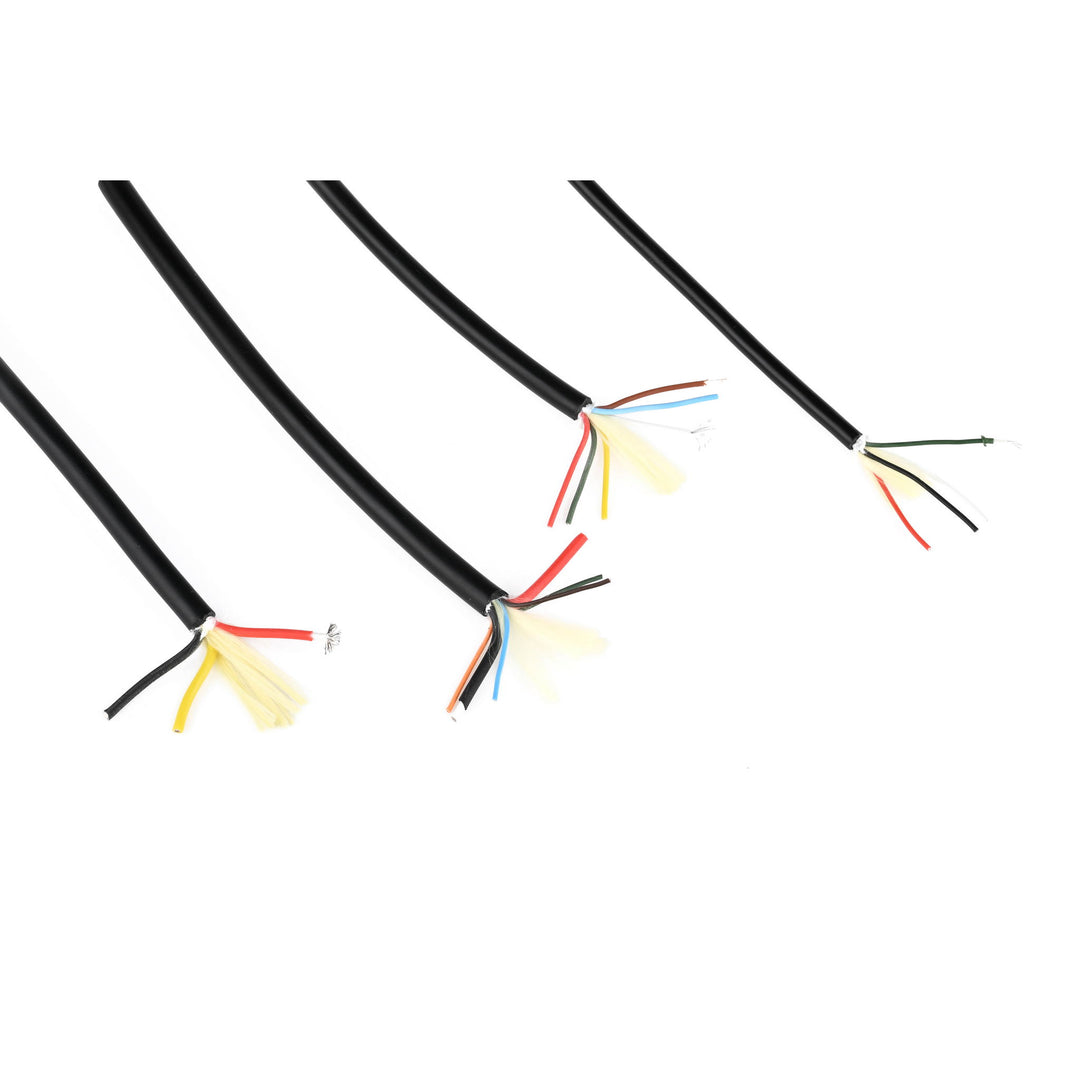

| Core Color | Red, Black, Yellow | White, Yellow, Green, Red, Blue, Brown | White, Black, Red, Green | Red, Black, Blue, Orange, Green, Brown | Red, Black, White, Green | Red, Black, Yellow |

| Overall Cable Diameter (mm) | 7.5±0.15 | 7±0.15 | 5.2±0.15 | 8±0.15 | 7.5±0.15 | 6.0±0.15 |

How to waterproof the cable ends?

Waterproofing methods depend on specific requirements, considering factors such as whether it is detachable, waterproof depth, lifespan requirements, environmental conditions, and connection methods (line-to-line, watertight enclosure outlet), etc.

- Simple Waterproofing Treatment: Use cable penetrator, resin potting, etc.

- Waterproofing Treatment within 1000 meters depth: Traditional encapsulation materials sealing, such as gel beads, gland heads used in pump cables, etc.

- Deepwater Waterproofing Treatment: Sealing with vulcanized rubber, pressing waterproof connectors, fixed joints made of polyurethane, etc.

What is the minimum order quantity?

The minimum order quantity is 1 meter, and prices decrease with larger quantities. Please contact us for bulk discount on large order volumes.

How to strip the cables?

Cable stripping can be done using diagonal pliers or a knife blade. Stripping tools or pneumatic/electric wire strippers are used for batch cutting. Kevlar inside may require separate cutting.

What happens if the bending radius exceeds the minimum bending radius?

There is a risk of cable jacket rupture with prolonged excessive bending, and prolonged exposure to ultraviolet radiation should also be avoided.

What is the operating temperature range?

The long-term operating temperature is -20°C to 80°C, and the storage temperature is -20°C to 50°C.

Can it be used if the cable jacket is damaged?

A damaged cable jacket may lead to short circuits or open circuits and can affect waterproofing.