The Subsea M10 Coupling Tube is a specialized underwater accessory designed to support two key use cases: the external relocation of penetrator-mounted components, and the extension of underwater cables when greater reach is required. Built with a threaded M10×1 body and paired with a locking gland nut, the Subsea M10 Coupling Tube enables secure, watertight integration into subsea systems operating at depth.

For penetrator-mounted devices such as underwater switches, indicator lights, depth or temperature sensors, the Subsea M10 Coupling Tube allows these components to be mounted away from crowded or inaccessible bulkheads. The internal cavity of the tube provides space for spliced wiring, and once sealed with epoxy, ensures long-term waterproofing and cable strain relief. This setup is especially valuable for control interfaces or indicators that need to be repositioned to more visible or reachable locations on the vehicle or housing.

Additionally, the Subsea M10 Coupling Tube functions as a cable extension solution for underwater components that include fixed-length leads. For example, if an underwater light or sensor has an insufficient cable length, the Subsea M10 Coupling Tube—when used with cable penetrators on both ends—enables the user to join a second length of underwater cable securely. The locking nut prevents cable kinking or displacement, while the interior can be filled with potting compound to maintain a robust watertight seal.

This simple yet effective component increases layout flexibility for custom ROVs, AUVs, and subsea enclosures, helping integrate multiple devices while preserving the integrity of pressure-rated cable paths. It is compatible with standard 7–8 mm outer diameter underwater cables, with optional use of heat shrink tubing or tape for smaller diameters to ensure proper sealing at the gland interface.

Sold Separately

The Subsea M10 Coupling Tube is fully compatible with all size variants of the Deep-Sea Underwater Cable, including multi-core configurations ranging from 3x16 AWG to 6-core hybrid builds. Its internal bore and locking nut are optimized for outer diameters between 5 mm and 8.5 mm, accommodating the full range of Blu-Sub's subsea cable offerings. This allows users to:

- Extend power or signal cables using in-line penetrators and potting compound

- Reposition penetrator-mounted devices such as lights, sensors, and switches

- Maintain full waterproofing and strain relief even in tight or remote mounting locations

Whether you're using 3-core, 4-core, or 6-core cable variants, the coupling tube provides a sealed connection point with mechanical support for subsea systems. For smaller cable diameters, heat shrink or tape can be used at the entry to ensure proper sealing within the gland. The Subsea M10 Coupling Tube is also compatible with third-party underwater cables that fall within the same outer diameter range.

Sold Separately

When using the Subsea M10 Coupling Tube, a single cable penetrator is installed at the cable-entry end to seal and secure the incoming cable. The internal cavity is then filled with potting compound (epoxy), providing long-term waterproofing and strain relief for the electrical joint. The locking nut and penetrator ensure mechanical sealing at the cable entry point.

Deep-Sea Cable Penetrators – These aluminum-body penetrators are designed for high-pressure and full-ocean-depth applications, where robust sealing and structural integrity are critical. Ideal for permanent or demanding installations using the coupling tube.

Depth Rating: Up to 1,000 m / 3,281 ft

Deep-Sea M10 Gland Cable Penetrators – Featuring a threaded body and compression gland, these M10-style penetrators are well suited for modular setups and offer excellent strain relief. Perfect for coupling tube assemblies where flexibility and repositioning are required.

Depth Rating: Up to 1,000 m / 3,281 ft

Low-Depth M10 Gland Cable Penetrators – A lightweight and cost-effective solution for shallow or low-pressure systems. These are a good match for prototyping or temporary cable extensions using the coupling tube in environments down to 100 m.

Depth Rating: Up to 100 m / 328 ft

Sold Separately

The Subsea M10 Coupling Tube can also be used as an inline housing for modular underwater cable connections. In this setup, a single Deep-Sea Cable Connectors – M10 Bulkhead is required at one end of the tube. An underwater cable enters through the opposite end, sealed in place using the locking nut and potting compound (epoxy) to ensure waterproofing and strain relief. The bulkhead provides a standard M10 interface for attaching detachable cable plugs or dummy caps, allowing for modular connections between subsea equipment while preserving sealing integrity.

Deep-Sea Cable Connectors – Female Socket & Male Plug

Modular in-line connectors designed to terminate underwater cables with sealed male or female plug ends. These connectors allow the Deep-Sea Underwater Cable to form reliable, removable connections between subsea devices and enclosures.

Deep-Sea Cable Connectors – M10 Bulkhead

Threaded panel-mount connector installed into the Subsea M10 Coupling Tube. It forms the mating interface for external male plug connectors and enables removable cable connections to the tube assembly.

Deep-Sea Cable Connectors – Dummy Sealing Cap

Used to protect unused M10 bulkhead connectors when not in use. Prevents moisture ingress and maintains waterproof integrity during storage, transit, or standby.

Sold Separately

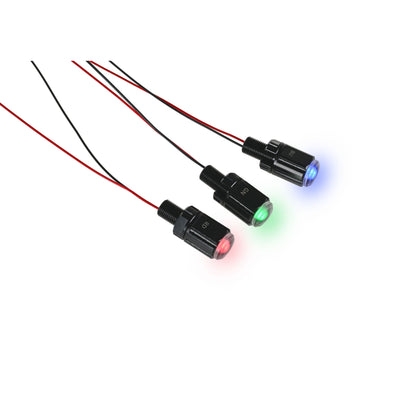

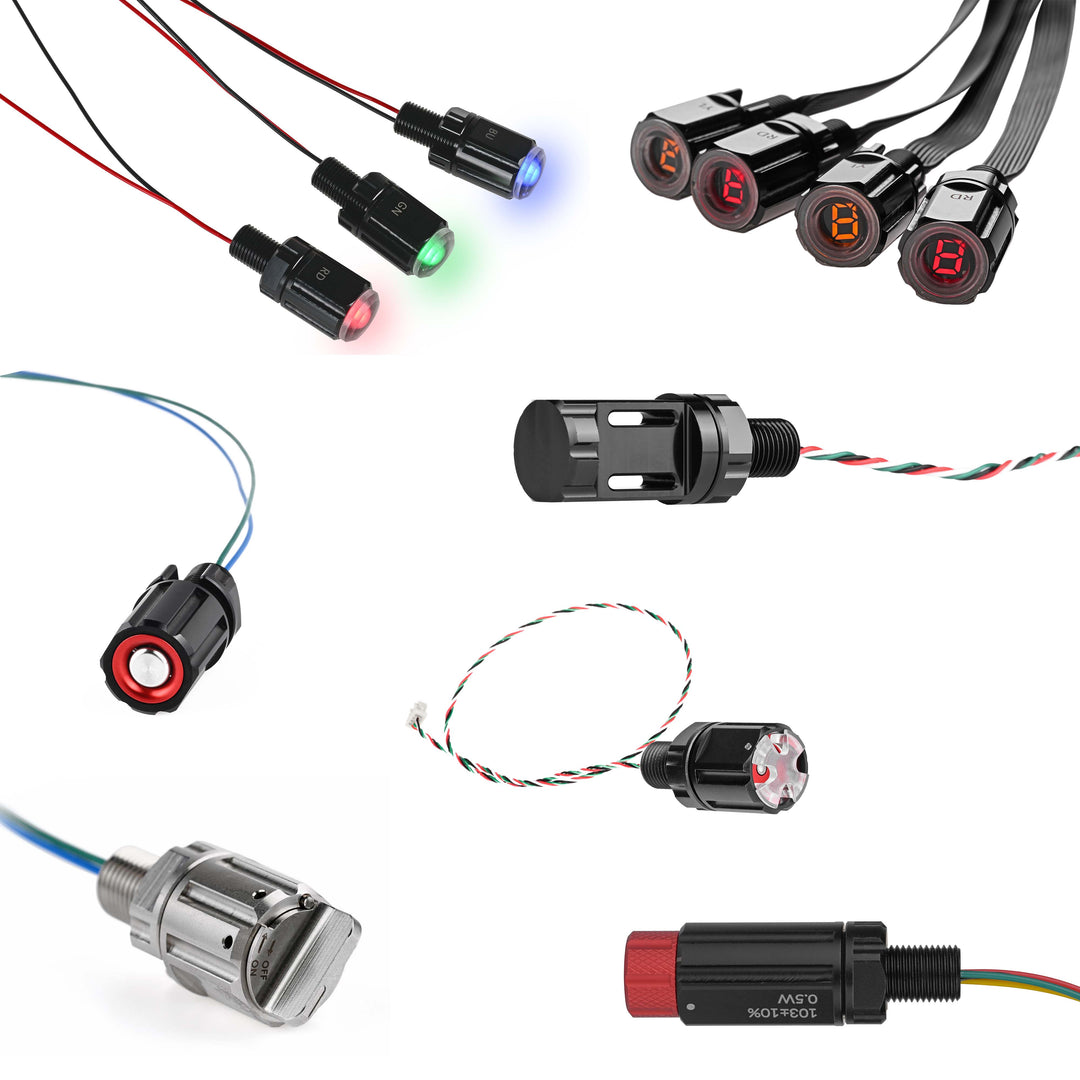

The Subsea M10 Coupling Tube is fully compatible with Blu-Sub’s range of M10-mounted subsea components. It allows these devices to be externally relocated from a bulkhead or enclosure to a more accessible or visible location. The tube provides internal space for spliced wiring and, once filled with epoxy, ensures a waterproof and strain-relieved electrical connection.

Subsea M10 Water Temperature Sensor

Monitors underwater temperature using a digital sensor head in a compact, epoxy-sealed M10 form factor.

Subsea M10 Depth Sensor

Measures pressure and calculates depth in real-time. Can be mounted directly to the coupling tube for external placement.

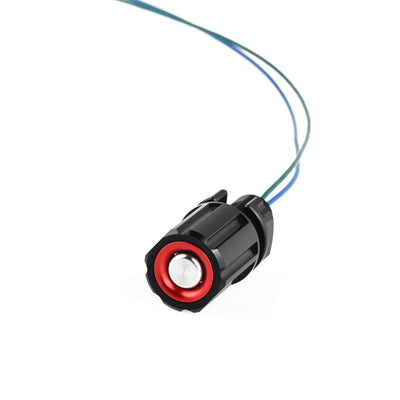

Subsea M10 Signal Indicator

Provides visual status feedback using a waterproof LED indicator housed in a rugged M10 shell, easily integrated into the coupling tube.

Subsea M10 7-Segment Display

Displays numeric or coded data underwater through a high-visibility LED screen mounted in an M10-compatible enclosure.

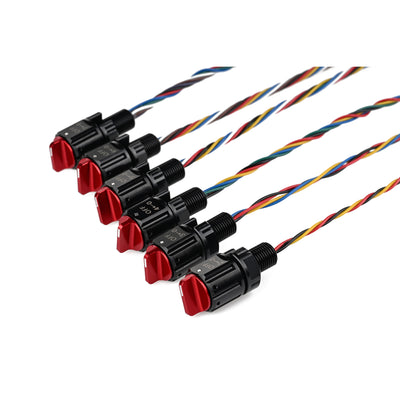

Subsea Switches & Potentiometers

A full lineup of M10-threaded input devices—such as the Subsea M10 Rotary Potentiometer, Tap Switch, Waveband Selector, and Pressure Trigger Switch—can be repositioned externally using the coupling tube for easier access and improved layout flexibility.

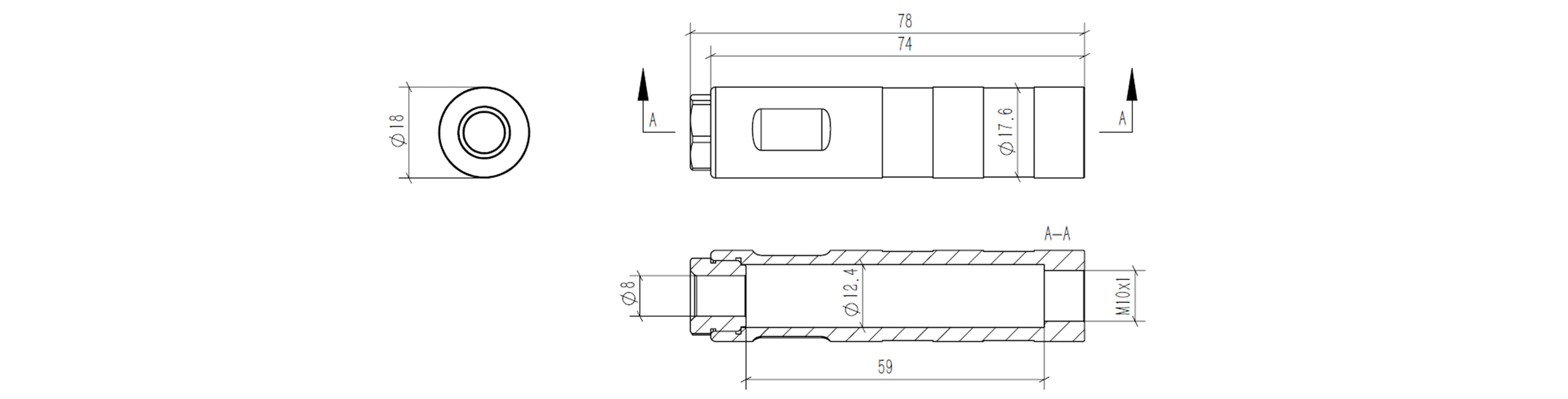

| Item | Subsea M10 Coupling Tube |

| Material | Aluminum, Black Anodized |

| Weight | 29 g |

| Thread Specification | M10×1 |

| Recommended Cable OD | 7–8 mm (or smaller with heat shrink/tape) |

| Locking Nut Included | Yes |

| Sealing Method | Cable enters via nut and is potted with adhesive |

| Primary Use Cases | External wiring of penetrators; underwater cable extension |

In some underwater equipment, one end of the watertight enclosure may be inaccessible by hand. In such cases, the cable from an indicator light or switch must be extended and repositioned. To achieve this, a Subsea M10 Coupling Tube and an extended underwater cable must be used and properly waterproofed.

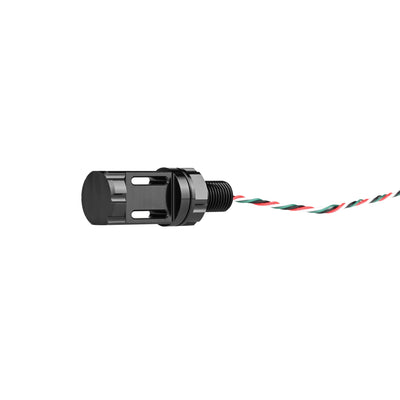

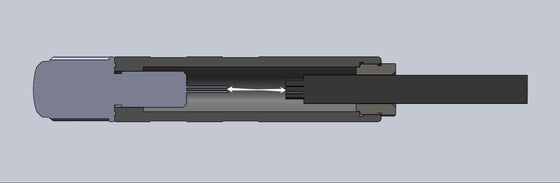

The Subsea M10 Coupling Tube consists of a threaded tube and a locking nut. The underwater cable passes through the locking nut into the tube, which is then filled with adhesive. The tube serves both as mechanical support and as a cavity for the potting compound, while the locking nut secures the cable, preventing excessive bending and ensuring full contact with the cured adhesive.

Specific method (take Subsea M10 Signal Indicator as an example):

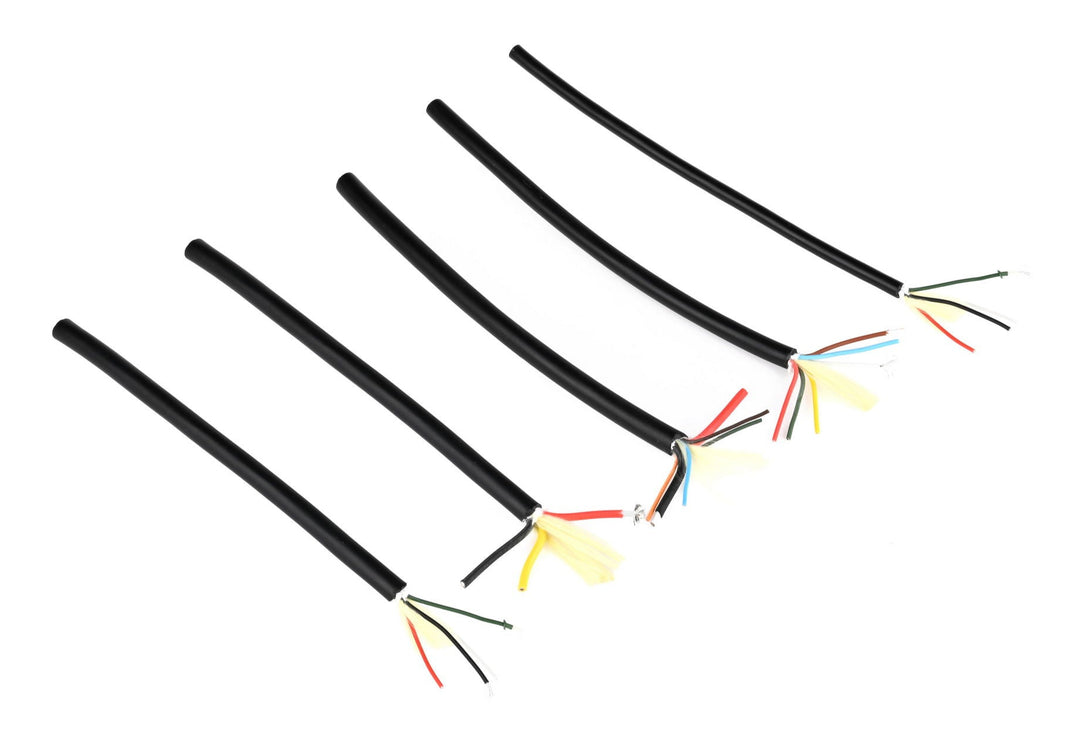

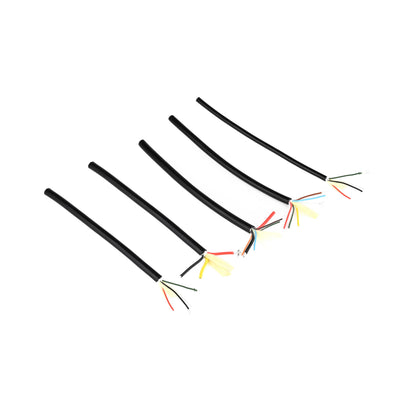

- Select an underwater cable with an outer diameter of 7–8 mm suitable for the M10×1 thread. Cut the cable to the required length and number of cores, and strip off the outer jacket.

If the cable’s outer diameter is less than 7 mm, it can still be used. In this case, wrap tape or a heat shrink tube around the section that enters the locking nut to ensure it fits snugly and remains centered. - Trim the indicator cable to an appropriate length and solder it to the extended underwater cable. Cover the soldered joint with a heat shrink tube.

- Clean all bonding surfaces with alcohol, including the inside of the Subsea M10 Coupling Tube and the exposed surfaces of the cables.

- Route the free end of the underwater cable through the coupling tube, then attach and secure the indicator onto the tube.

- Insert the cable end into the tube and fill the internal cavity with adhesive. Finally, screw on the locking nut to compress and hold everything in place.

- Allow the adhesive to fully cure. Do not move or disturb the assembly while it is curing.

- Refer to the image below for the correct assembly configuration. The cable must be fully embedded in the adhesive and properly centered to achieve a watertight seal.

Once these steps are completed, the bulkhead penetrator devices can be safely submerged and routed to alternative locations. For more detailed guidance, see our Waterproofing Procedure for Penetrator Devices.

What is it used for?

This component serves two primary purposes:

1. Converts internal bulkhead-mounted penetrator devices into external cable-mounted devices for easier access and wiring.

2. Extends underwater cables when the existing cable length is insufficient, such as with indicator lights or switches that need to be relocated away from the main housing.

How does it ensure waterproofing?

The Subsea M10 Coupling Tube includes a main tube and a locking nut. The cable is routed through the locking nut into the tube and sealed with adhesive. The locking nut secures the cable, prevents excessive bending, and ensures full contact between the cable and the cured adhesive for effective waterproofing.

Can I use it to extend pre-wired products like underwater lights?

Yes, the Subsea M10 Coupling Tube is ideal for extending the cables of pre-wired underwater devices. Simply select an appropriate cable diameter (7–8 mm is ideal for M10×1), strip and join the internal wires, apply heat shrink tubing, insert through the Subsea M10 Coupling Tube, and fill with adhesive before sealing with the locking nut.

What if my cable is smaller than 7 mm in diameter?

You can still use the Subsea M10 Coupling Tube. Wrap the cable section near the locking nut with tape or heat shrink tubing to increase its outer diameter, ensuring it fits snugly in the locking nut and stays centered during sealing.

Does the glue need to fully cure before use?

Yes, allow the adhesive to fully cure without moving the assembly. Full contact and a centered cable are critical for achieving reliable waterproof performance.