This polymer flange is a single-piece end-cap and flange assembly, depth rated to 30 m based on sealed pressure testing (no holes, no vacuum evacuation). It includes a built-in safety factor to ensure reliable performance in shallow to mid-depth underwater deployments.

Installation is aided by the included Opening Stickers, which serve as drilling templates for adding cable penetrators, vents, or other devices. If neither end of the enclosure has an opening, internal air pressure may resist insertion of the flange. For easier assembly and proper pressure equalization, at least one opening—such as a vent port—is recommended.

The flange body includes dual radial O-ring grooves to maintain a watertight seal against the interior wall of compatible tubes. A small notch on the piston step is designed to assist with disassembly by allowing a tool to gently break the seal without damaging the flange or the enclosure tube.

Installation and Maintenance Tips: Whether installing into an aluminum or acrylic tube, it is critical to thoroughly lubricate all O-rings with a high-quality compound like O-Ring Lubricant – MOLYKOTE® 111 Compound before inserting the end-cap. Proper lubrication helps prevent damage to the O-rings, the end-cap, and the tube itself, and greatly reduces the risk of leaks. Do not attempt to force the end-cap into place if the O-rings are dry or not fully lubricated, as this can lead to deformation or tearing of the O-rings and may permanently damage the sealing surfaces.

To maintain sealing performance, avoid using adhesives or threadlockers, as these can chemically degrade the flange material. If the O-ring sealing surface is scratched, or if improper drilling damages the flange, it should be replaced. Drilling should be performed using a slow feed rate and a vertical guide or drill press—especially for holes larger than 10 mm—to avoid internal chipping. Improper drilling or physical damage is not covered under warranty.

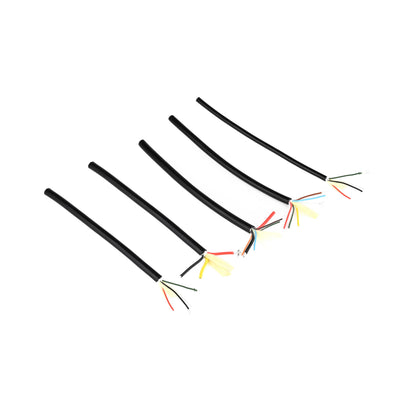

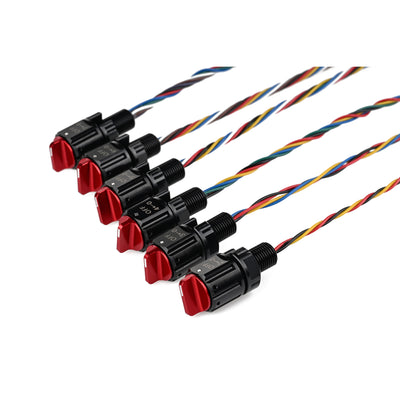

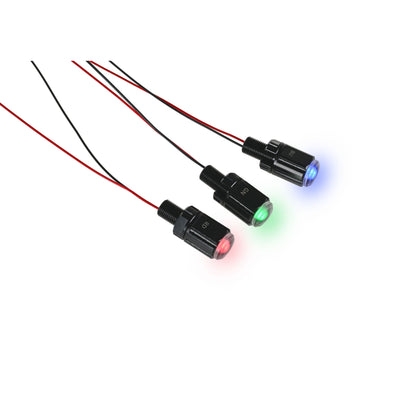

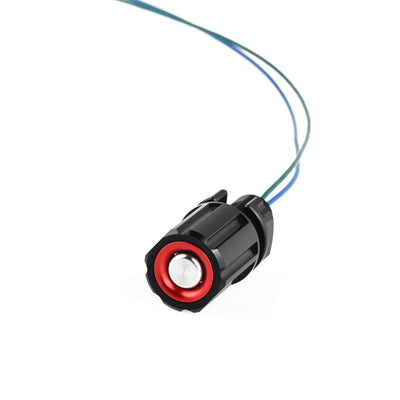

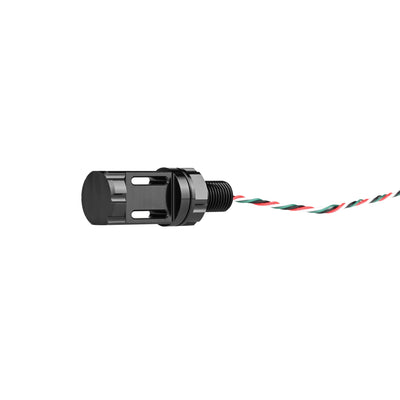

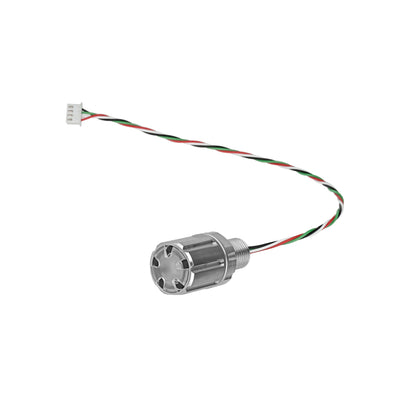

Sold Separately

The Subsea Enclosure Aluminum Tube is fully compatible with the Polymer Flange – 115 mm, which features an integrated flange and end-cap design for direct mounting without additional hardware.

While the Subsea Enclosure Aluminum Tube is engineered for deep-sea performance, pairing it with the Polymer Flange is best suited for shallow to moderate depth applications where reduced weight, ease of assembly, and corrosion resistance are priorities.

This configuration is depth-rated to 30 m / 98 ft under sealed test conditions and is ideal for low-depth marine deployments, prototyping, and budget-sensitive underwater systems.

Sold Separately

The Subsea Enclosure Acrylic Tube is fully compatible with the Polymer Flange – 115 mm, which integrates both the flange and end-cap into a single component for direct sealing—no separate flange is required.

Molded from black glass-filled Nylon, the flange offers durable watertight performance for shallow to mid-depth use. It is corrosion-resistant and ideal for cost-sensitive subsea projects.

This configuration is depth-rated to 30 m / 98 ft under sealed test conditions. It is recommended for enclosures that do not exceed moderate depths, especially where ease of machining and installation are priorities.

Sold Separately

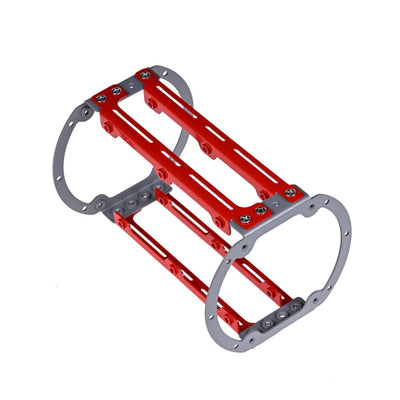

Electronic Tray Set for Enclosure Tube

Offers a structured and secure platform for mounting internal electronics, batteries, and PCB assemblies inside Blu-Sub enclosures. Designed for use with 85 mm, 115 mm, and 165 mm tubes, the tray system includes base mounts, shelf supports, and all required hardware. When used with the Subsea Polymer Flange & End-Cap, the base mount attaches directly to the polymer flange using screws—ensuring stable and precise support for internal components. Compatible with both acrylic and aluminum tubes, the tray system enables efficient internal layout of subsea electronics.

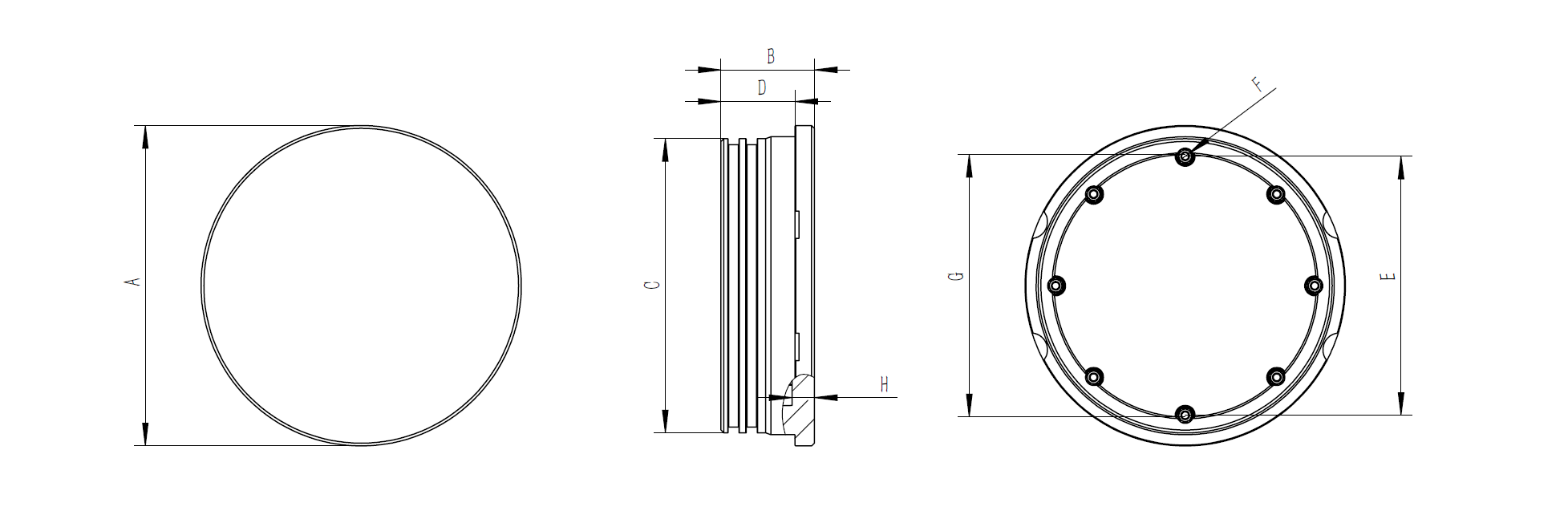

| Spec | 115 mm Polymer Flange |

|---|---|

| Material | Nylon + Glass Fiber |

| Pressure Resistance Depth | 30 meters (tested, no holes) |

| Weight | 161 g |

| Outer Diameter A | Ø115 mm |

| Height B | 33.5 mm |

| Piston Diameter C | Ø105.6 mm |

| Piston Length D | 26.5 mm |

| Inner Mounting Hole Circle E | Ø93 mm |

| Inner Mounting Hole F | M3 |

| Maximum Inner Wall Diameter G | Ø94 mm |

| End Face Thickness H | 8 mm |

*The listed pressure-resistant depth is based on test data under sealed conditions (without openings or vacuum evacuation) and includes a built-in safety factor. For single deployments at maximum depth, the duration should not exceed 300 hours. For extended or repeated use at full depth, we recommend selecting a more robust enclosure configuration such as the Subsea Enclosure Aluminum Tube, paired with the Subsea Aluminum Flange and Subsea Aluminum End-Cap.

A dimension drawing is provided below for reference.

Can the polymer flange be used at full depth rating?

While the polymer flange is rated for shallow to moderate depths, it may not be suitable for extreme depths compared to aluminum or glass counterparts. Always test under controlled conditions before use in critical deployments.

Is this compatible with Blu-Sub aluminum tubes?

Yes — the polymer flange is designed to be compatible with Blu-Sub aluminum subsea tubes of corresponding diameters.

Does the polymer flange include mounting hardware?

No — mounting hardware such as screws or penetrator fittings must be sourced separately depending on your specific installation setup.

Is the polymer flange transparent?

No — the flange is opaque and is not intended for optical applications. It is best suited for non-visual sealing and structural support.

Can I use this flange in corrosive environments?

Yes — the polymer material offers good resistance to corrosion in marine and freshwater environments, making it a lightweight and durable alternative to metal flanges for certain applications.

Can I apply thread adhesive or sealant to this flange?

No — most polymer materials are incompatible with thread adhesives or sealants. These chemicals can weaken the material and lead to cracks or leaks over time.

Can I reuse a flange if the O-ring groove or sealing surface is scratched?

No — if the sealing surface is damaged in any way, the flange should not be reused. A scratched groove may result in sealing failure and water ingress.

Does this flange require O-ring lubrication?

Yes — all O-rings should be lubricated before use with a high-quality compound such as MOLYKOTE® 111 O-Ring Lubricant. This ensures smooth insertion, reduces risk of tearing, and helps maintain a watertight seal.

Why does the flange resist insertion if there are no holes in the enclosure?

With no vent holes, internal air pressure can build up and resist the flange being fully seated. Adding a small hole—such as a vent port—allows pressure to equalize and improves installation ease.

What is the purpose of the notch on the piston step?

The notch is designed for tool-assisted disassembly. It allows a small prying tool to break the seal gently, helping you remove the flange without damaging the tube or O-rings.

Can I request a replacement if I scratch the flange during drilling?

No — damage resulting from improper drilling or installation is not covered under warranty. Please ensure all drilling is done carefully with appropriate tools and techniques.

What type of drill bit should I use?

Use a sharp, standard twist drill bit with a vertical drill press or guide. Drill slowly with steady pressure to avoid cracking or chipping, especially for holes larger than 10 mm.

Can I insert the flange without O-rings?

While possible, inserting without O-rings is not recommended. It may scratch the interior of the tube and compromise future sealing performance. Always use properly lubricated O-rings for a smooth, secure fit.