Metric Sealing Plug (Blank) components are precision-machined plugs used to seal unused penetrator ports on subsea enclosures. They help ensure the pressure housing remains watertight by blocking off ports not currently used for cables, sensors, or connectors. Available in standard metric thread sizes — M6x1, M8x1, M10x1, M14x1.5, and M16x1.5 — they are compatible with a wide range of common subsea interface ports.

These sealing plugs are tested to withstand pressures at depths up to 1,000 meters. The included brown O-rings provide durable sealing performance across -25 to 60 °C in air and -4 to 40 °C in water. The typical design lifetime is up to 3 years or 300 open/close cycles, depending on installation and usage conditions.

Sold Separately

Subsea Aluminum End-Cap

Designed with pre-drilled ports or blank locations that support direct installation of Blu-Sub Metric Sealing Plug (Blank) products in standard thread sizes such as M6, M8, M10, M14, and M16.

Subsea Polymer Flange & End-Cap

Can be user-drilled to accept Blu-Sub Metric Sealing Plug (Blank) units in a range of metric thread sizes for shallow-water or modular assemblies.

Subsea Watertight Enclosure Box

Includes 20 pre-drilled M10 ports for fast integration of Blu-Sub Metric Sealing Plug (Blank) components in sealed electronic housing builds.

| Bulkhead Size | Material | Appearance | O-ring Size | O-ring Material |

|---|---|---|---|---|

| M6x1 Metric Sealing Plug (Blank) | 6061 Aluminum | Black Anodized | Ø7 x 1.5 | FKM75 Brown Fluorine Rubber |

| M8x1 Metric Sealing Plug (Blank) | 6061 Aluminum | Black Anodized | Ø10 x 1.5 | FKM75 Brown Fluorine Rubber |

| M10x1 Metric Sealing Plug (Blank) | 6061 Aluminum | Black Anodized | Ø12 x 1.5 | FKM75 Brown Fluorine Rubber |

| M14x1.5 Metric Sealing Plug (Blank) | 6061 Aluminum | Black Anodized | Ø17 x 1.5 | FKM75 Brown Fluorine Rubber |

| M16x1.5 Metric Sealing Plug (Blank) | 6061 Aluminum | Black Anodized | Ø20 x 1.5 | FKM75 Brown Fluorine Rubber |

| Performance Characteristics | Metric Sealing Plug (Blank) |

|---|---|

| Maximum Rated Depth | Related to actual sealing and scenario / Sample testing up to 1,000 meters |

| Design Lifetime | Related to actual sealing and scenario / Sample testing up to 3 years or 300 cycles |

| Temperature Rating (air) | Related to actual sealing and scenario / Samples testing from -25 to 60°C |

| Temperature Rating (water) | Related to actual sealing and scenario / Samples testing from -4 to 40°C |

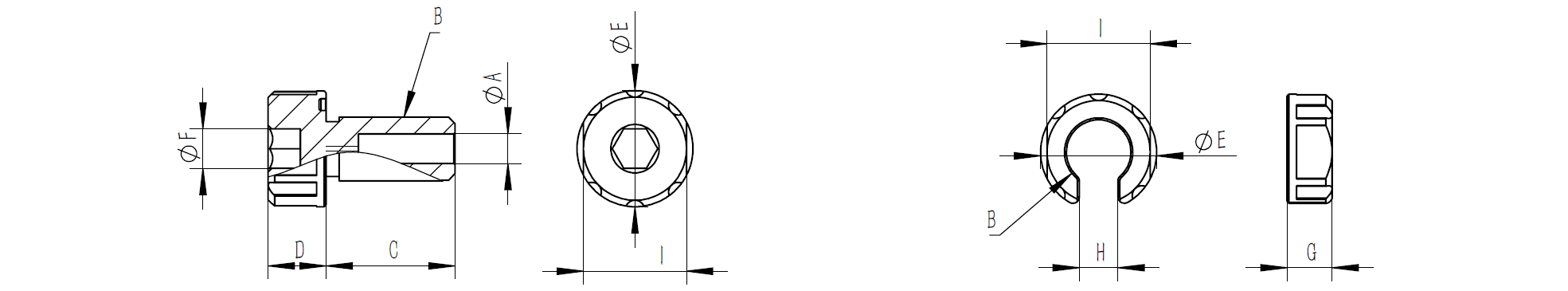

| Bulkhead Size | M6x1 | M8x1 | M10x1 | M14x1.5 | M16x1.5 |

|---|---|---|---|---|---|

| Seal Sizes (A) | 2.5 | 4 | 5 | 8.5 | 10 |

| Bulkhead Thread (B) | M6x1 | M8x1 | M10x1 | M14x1.5 | M16x1.5 |

| Bulkhead Thread Length (C) | 10 | 20 | 20 | 26 | 26 |

| Assembled Height from Endcap (D) | 9 | 9 | 9 | 9 | 9 |

| Overall Outer Diameter (E) | 13 | 15 | 18 | 24 | 30 |

| Width between Opposite Sides of Hex Socket (F) | 6 | 6 | 6 | 6 | 6 |

| Nut Height (G) | 4 | 6 | 7 | 8 | 9 |

| Nut Slot Width (H) | 3.5 | 4.5 | 6 | 9 | 10 |

| Width between Opposite Sides of Wrench Groove (I) | 12 | 13 | 16 | 22 | 27 |

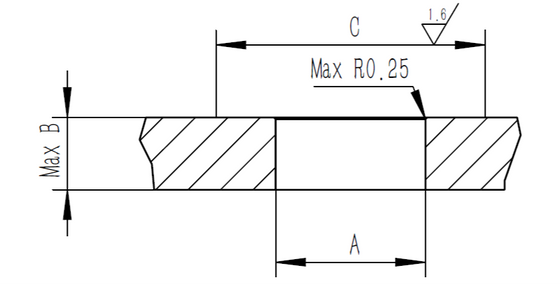

| Recommended Size | M6x1 | M8x1 | M10x1 | M14x1.5 | M16x1.5 |

|---|---|---|---|---|---|

| Recommended Bulkhead Through Hole Size (A) | Ø6.1 ± 0.1 | Ø8.1 ± 0.1 | Ø10.1 ± 0.1 | Ø14.1 ± 0.1 | Ø16.1 ± 0.1 |

| Hatch Cover Thickness (B) | 6 mm | 14 mm | 13 mm | 18 mm | 17 mm |

| Surface Range (C) | 15 mm | 17 mm | 20 mm | 26 mm | 32 mm |

Installation Guidance

- Attention: The top hex socket is intended only for light tightening or loosening during initial positioning. It is not suitable for applying high torque. To achieve proper installation torque, use a suitable wrench on the flat sides of the bulkhead.

- For tightening, hold the opposite flats of the bulkhead and torque the nut properly.

- In compact spaces, a pair of snap ring pliers can help rotate the blank via the internal semi-circle groove.

- Washers or anti-slip pads are recommended between nut and enclosure wall to prevent loosening.

- Do not use gasket-like friction pads.

- Loctite threadlocker is advised on threads — avoid getting any on the gasket or sealing surfaces.

- Note: While the external black anodizing is preserved, interior threads or machined faces that contact enclosure walls may exhibit bare aluminum depending on installation — this does not affect sealing or performance.

Do I need special tools to install or remove the blank?

Not necessarily. The top groove is designed for use with snap ring pliers or similar tools. However, for proper torque, it's recommended to use a wrench on the opposite flat sides of the bulkhead.

Should I apply thread locker during installation?

Yes, applying Loctite thread locker is recommended to prevent loosening. Avoid getting the adhesive on the gasket or sealing surfaces.

Is the hex socket suitable for final tightening?

No, the hex socket is only intended for quick tightening or loosening. Final torque should be applied using a wrench on the flat sides of the bulkhead.

Can I use this with Blu-Sub aluminum or acrylic end caps?

Yes, as long as the thread size and through-hole dimensions match, it is compatible with both aluminum and acrylic end caps.