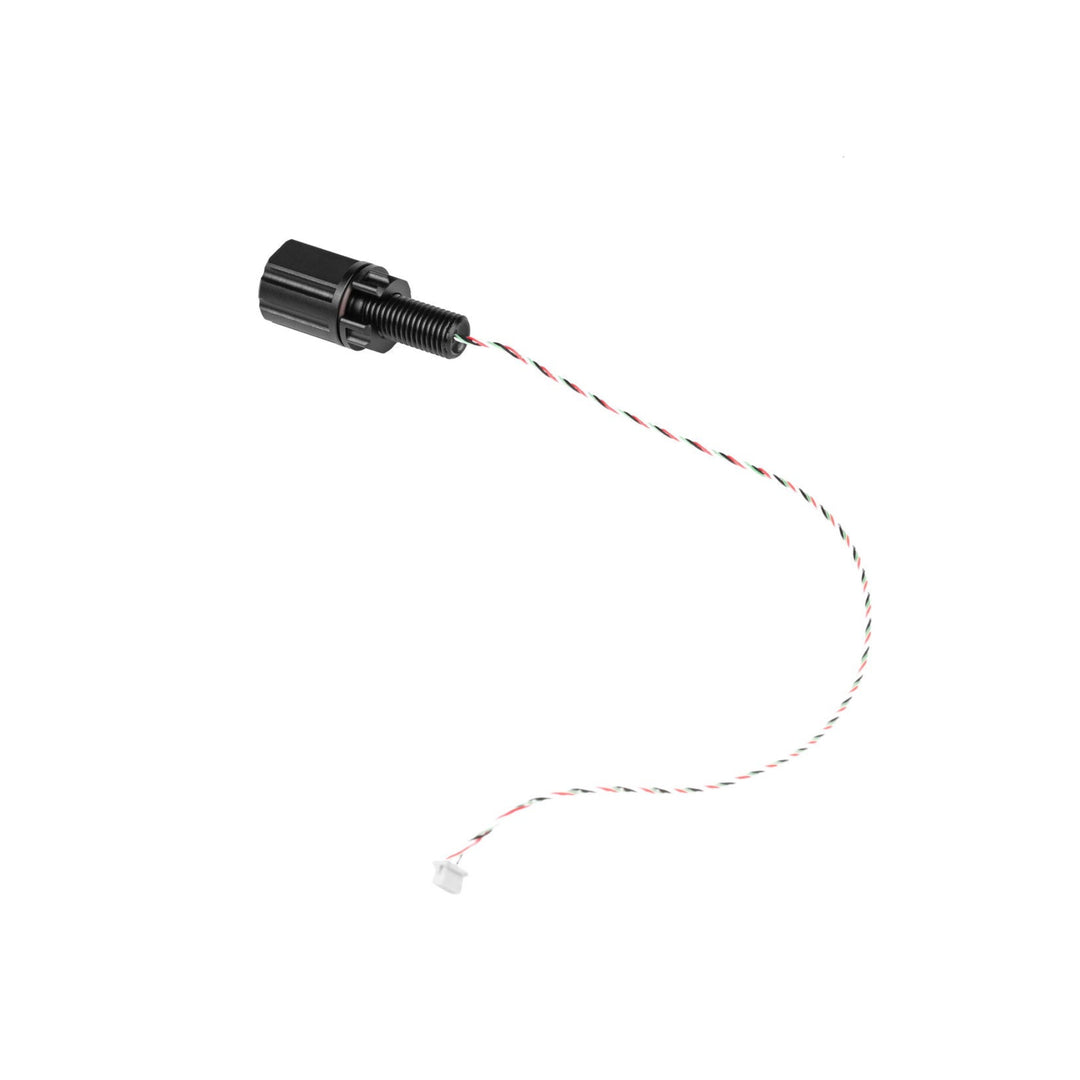

The Subsea M8 Depth Sensor is built around the MS583730BA digital pressure chip, delivering high-resolution barometric readings for subsea depth applications. Its compact M8 threaded housing is ideal for use in smaller enclosures or sensor arrays where space and weight are at a premium. The included O-ring and nut support secure bulkhead installation in tight marine platforms such as ROVs, mini-submersibles, and sensor nodes.

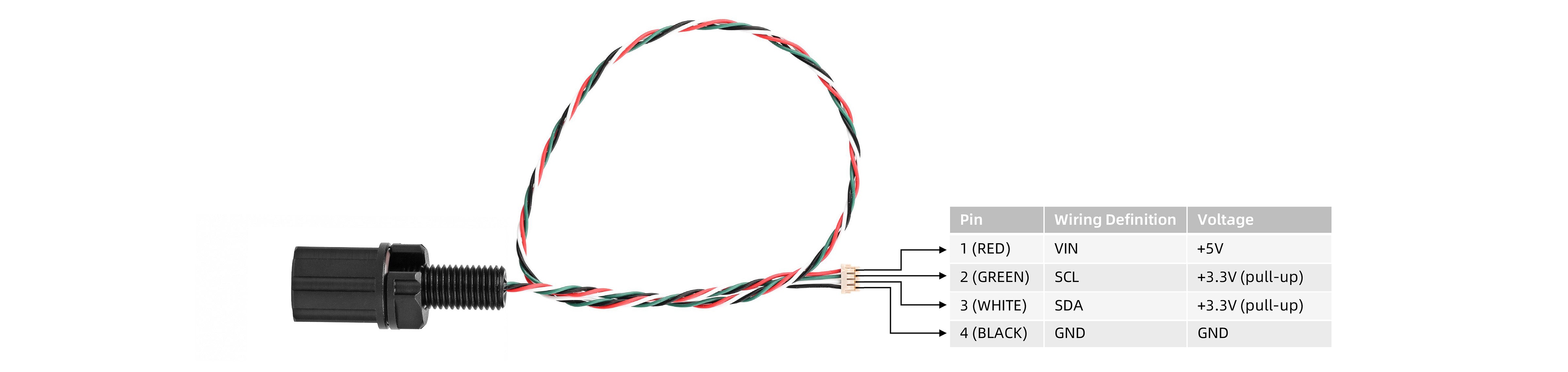

Like its larger counterpart, the M8 sensor communicates via I²C and uses a DF13-4S connector with standard logic-level wiring (VIN, GND, SDA, SCL), making it suitable for ArduSub, Pixhawk, and custom embedded systems. It operates efficiently on 5 V with minimal current draw, making it especially suitable for mobile systems. Unlike the M10 version, the protective cap on this model is fixed and not designed for removal or field cleaning.

To ensure long-term accuracy, all MS5837-based sensors—including this model—must be removed from water and dried for at least two hours per day, as recommended by the chip manufacturer. For deployments requiring continuous immersion or greater mechanical durability, consider the Subsea M14 Metal Diaphragm Depth Sensor (0–35 Bar / 0–350 m). For a removable-cap version in a larger housing, see the Subsea M10 Depth Sensor (0–30 Bar / 0–300 m).

Sold Separately

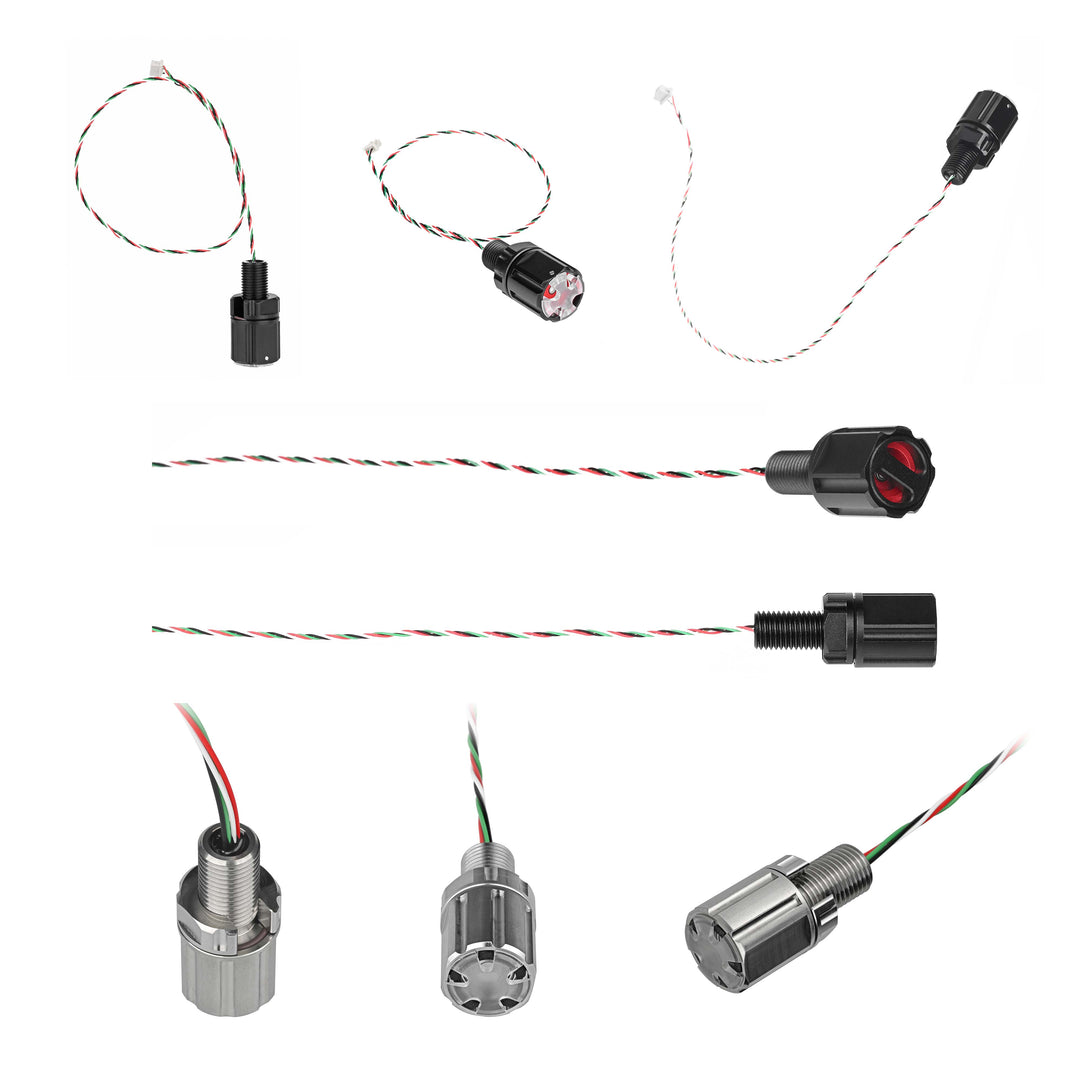

While the M8 sensor is ideal for compact installations and embedded platforms, Blu-Sub also offers larger models with enhanced durability, higher pressure ratings, and alternate communication options.

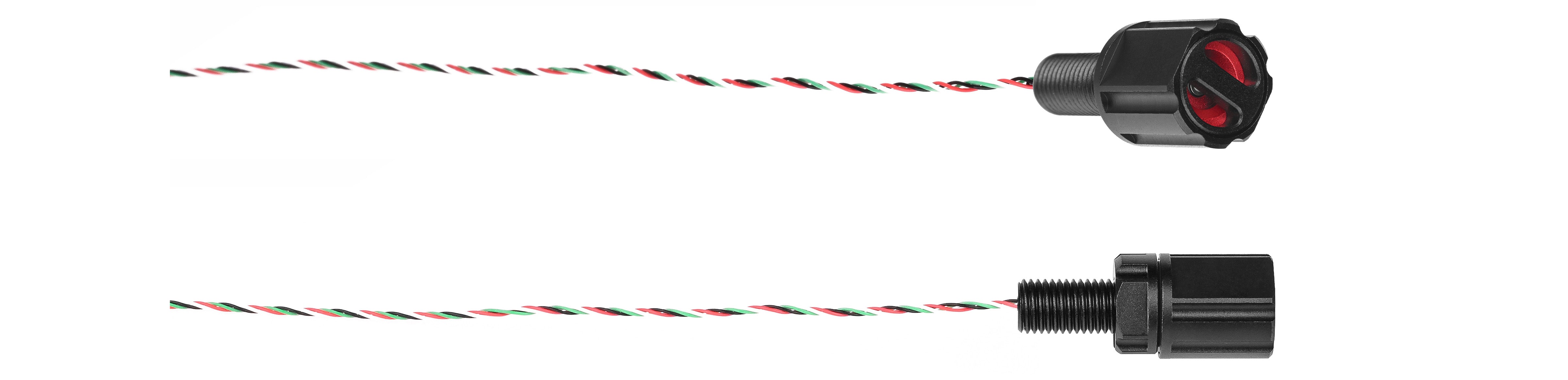

Subsea M10 Depth Sensor (0–30 Bar / 0–300 m)

I²C-based depth sensor with a removable protective cap and M10 threaded body, offering easier field servicing and rugged enclosure mounting.

Subsea M14 Metal Diaphragm Depth Sensor (0–35 Bar / 0–350 m)

High-durability sensor with a stainless steel diaphragm and oil-filled core, designed for long-term submersion and high-pressure deployments using USART communication.

Sold Separately

The Subsea M8 Depth Sensor installs easily into a variety of Blu-Sub subsea enclosures using a standard M8 mounting hole. Each housing supports secure sealing and reliable operation at depth. Ensure the selected enclosure provides adequate panel thickness and internal clearance for the sensor body and wiring.

Subsea Watertight Enclosure Box

Compact aluminum enclosure rated to 300 m, pre-drilled with twenty M10 ports—ideal for sensors, switches, or signal indicators. A custom-drilled port is required for M8 sensors.

Subsea Enclosure Acrylic Tube

Transparent cast acrylic body rated to 250 m, compatible with Blu-Sub aluminum end-caps. Select an end-cap with an M8 hole to accommodate this sensor.

Subsea Enclosure Aluminum Tube

Rugged aluminum housing rated to 1,000 m. Use with matching aluminum end-caps that include an M8 hole for proper sensor installation and sealing.

| Specification | Subsea M8 Depth Sensor (0–30 Bar / 0–300 m) |

|---|---|

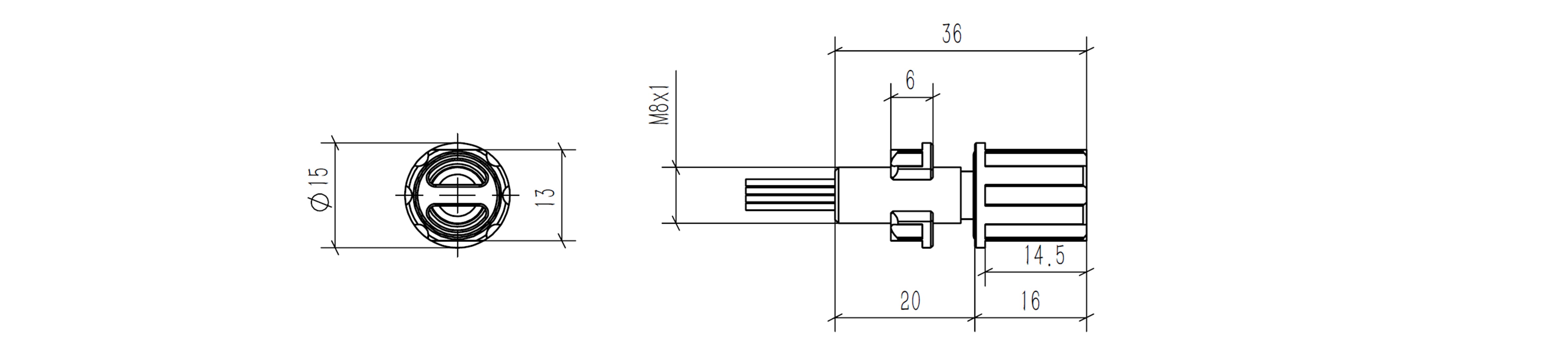

| Thread | M8×1 |

| Voltage | 5 V |

| Peak Current | 1.5 mA |

| Communication Methods | IIC |

| IIC Logic Voltage (SDA and SCL) | 3.3 V |

| IIC Address | 0x76 (1110110 b) |

| Wiring Definition | Red: VIN, Green: SCL, White: SDA, Black: GND |

| Connector Type | DF13-4S-1.25C |

| Wire Length | Approx. 300 mm |

| Operating Pressure | 0–30 Bar |

| Operating Depth | 0–300 m |

| Overpressure Pressure | 50 Bar |

| Pressure Resolution | 0.2 mbar |

| Relative Accuracy | ±200 mbar |

| Operating Temperature | -20 ~ 85 ℃ |

| Temperature Accuracy | ±4 ℃ (0–60 ℃) |

NOTE: On the M8 version, the protective cover is fixed and cannot be removed. This does not affect performance or functionality.

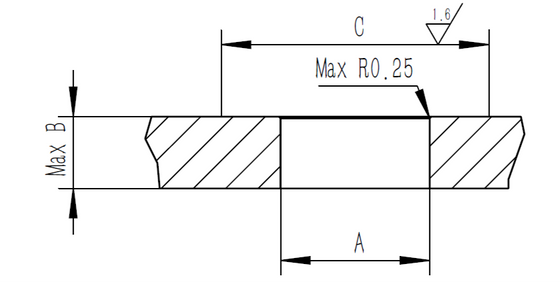

| Recommended Size | M8 Depth Sensor |

|---|---|

| Recommended Bulkhead Through Hole Size (A) | Ø8.1 ± 0.1 mm |

| Hatch Cover Thickness (B) | 14 mm |

| Surface Range (C) | 17 mm |

What's the difference between this and the M10 version?

The M8 and M10 sensors use the same pressure sensor chip and have identical performance. The only differences are the thread size and that the M8 version has a fixed (non-removable) protective cover.

Can the wire be extended?

Yes, but long wire runs or multiple I²C devices on the same bus may affect timing. This can be mitigated by using stronger I²C pull-up resistors or adding an I²C repeater chip.

How do I read data without using ArduSub? Are code examples available?

The sensor chip is commonly used and well-documented. Open-source sample code is widely available for integrating the sensor into your own system.

What if the white soft membrane is damaged?

If the membrane is broken or punctured, the sensor should no longer be used, as this compromises its sealing and accuracy.

Can it be used in seawater and freshwater?

Yes. The sensor is suitable for use in both seawater and freshwater environments.

What are the advantages compared to other manufacturers?

• High reliability: Built to precise specifications to maximize sensor lifespan and measurement accuracy.

• Durable design: The built-in protective cover helps prevent damage from debris such as sand or rocks, protecting the sensitive sensor membrane.

Can the protective cover be removed?

No, the protective cover on the M8 depth sensor is fixed and not designed to be removed.