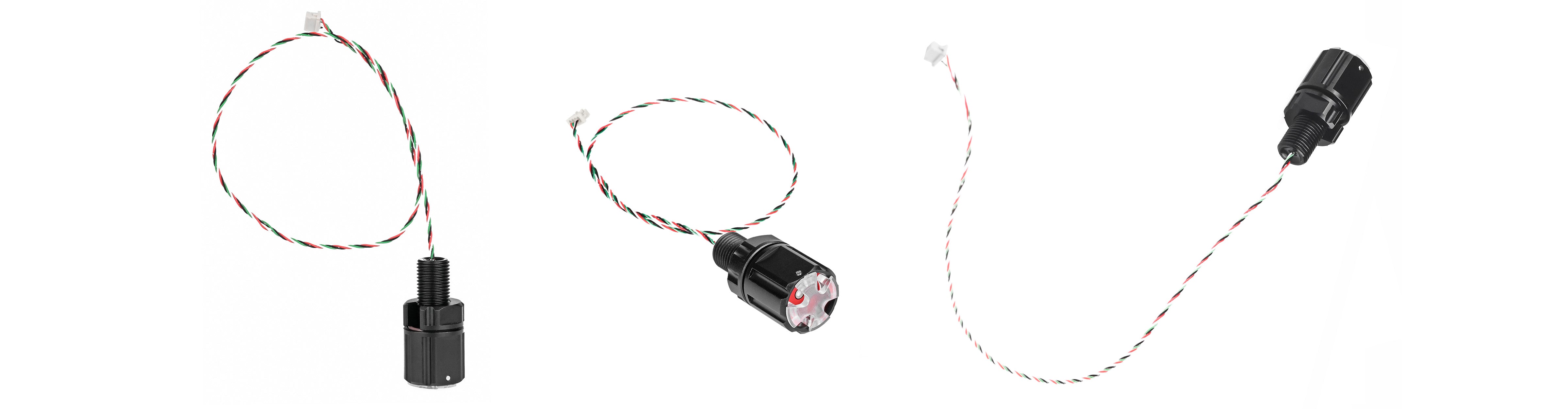

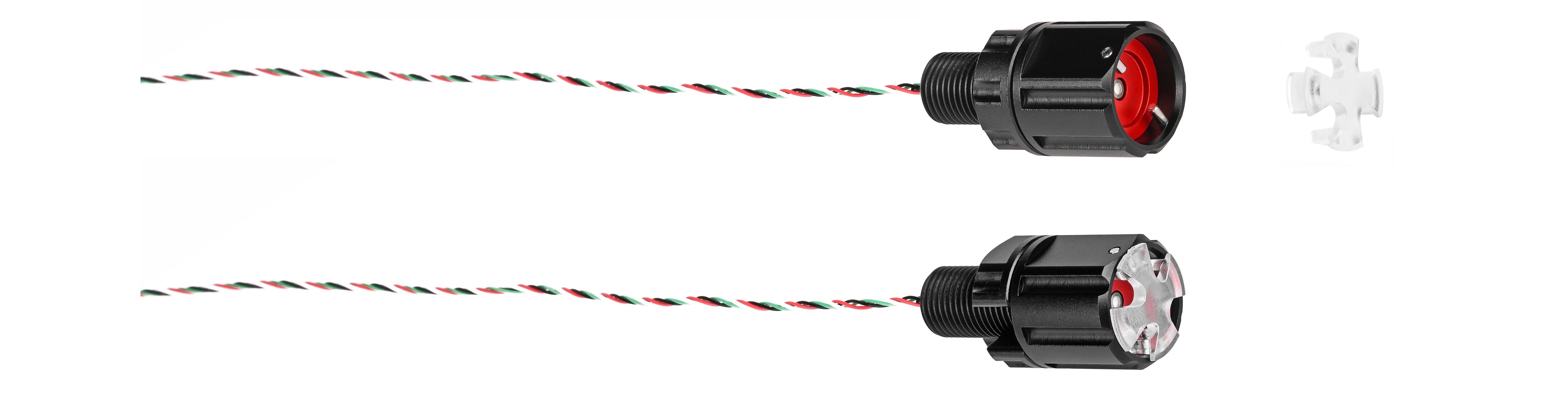

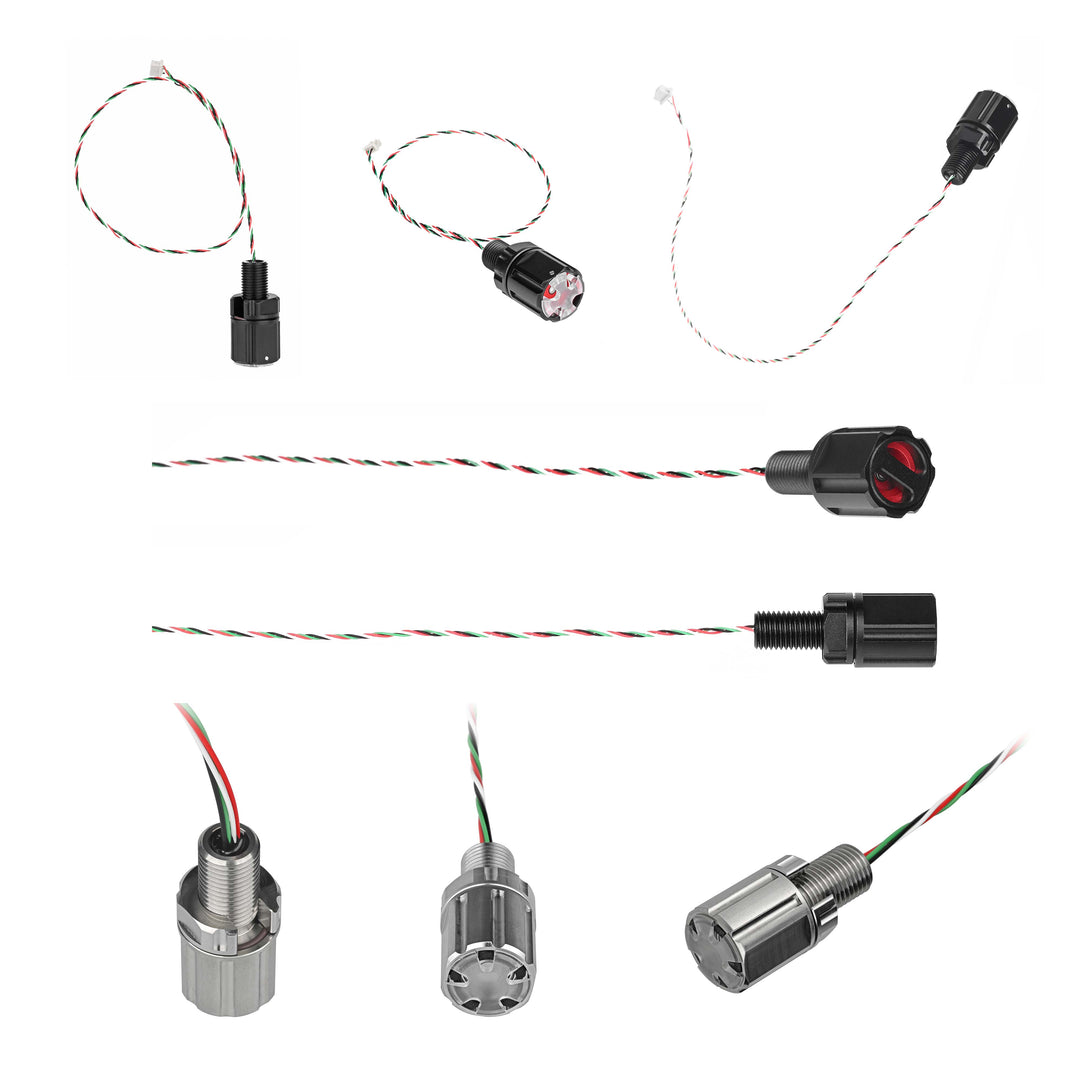

The Subsea M10 Depth Sensor is designed around the MS583730BA digital pressure sensor, offering high-resolution barometric readings in underwater applications. Its M10×1 threaded body enables secure integration into enclosure walls or sensor pods, with an included O-ring and nut for simple mounting. The compact form factor makes it an excellent choice for ROVs, underwater drones, and embedded sensor systems with tight space constraints.

Built for compatibility, this sensor uses I²C communication and includes clearly labeled DF13 wiring (VIN, GND, SDA, SCL), allowing developers to incorporate it into a wide range of control systems beyond ArduSub. Its low power requirements and high depth rating (300 m) make it a strong candidate for mobile and battery-powered systems. The replaceable protective cap helps safeguard the pressure-sensitive diaphragm during operation and cleaning, especially in environments with sand or particulates.

To maintain optimal performance, it is essential that sensors using the MS5837 chip be dried out of water for at least two hours daily. This prevents long-term signal drift and preserves measurement accuracy. Systems requiring uninterrupted submersion or lower maintenance intervals should instead consider the Subsea M14 Metal Diaphragm Depth Sensor (0–35 Bar / 0–350 m), which is more suited to continuous-use scenarios.

Sold Separately

The M10 sensor offers a balanced design with a removable cap and standard I²C interface. For smaller form factors or enhanced pressure durability, consider the additional options below.

Subsea M8 Depth Sensor (0–30 Bar / 0–300 m)

Compact I²C-compatible depth sensor with an M8 threaded body and fixed protective cap, suitable for embedded systems and tight space constraints.

Subsea M14 Metal Diaphragm Depth Sensor (0–35 Bar / 0–350 m)

High-reliability depth sensor featuring a stainless steel diaphragm and oil-filled sensing chamber, designed for continuous submersion and USART-based data output.

Sold Separately

All Blu-Sub depth sensors are designed for seamless installation into a range of subsea enclosures. Whether you're building a compact sensor pod or a deep-rated control system, each housing supports proper mounting and sealing of M8, M10, or M14 threaded sensors.

Subsea Watertight Enclosure Box

Compact aluminum housing rated to 300 m, pre-drilled with twenty M10 ports for direct integration with M10-threaded sensors. For M14 sensors, a custom-drilled port is required.

Subsea Enclosure Acrylic Tube

Transparent cast acrylic tube for 20–250 m depths, compatible with Blu-Sub aluminum end-caps. Select an end-cap with the correct hole size (M8, M10, or M14) for your chosen sensor.

Subsea Enclosure Aluminum Tube

Deep-rated aluminum tube for up to 1,000 m operation. Requires matching aluminum end-caps drilled with the appropriate threaded hole (M8, M10, or M14) for sensor mounting.

Sold Separately

The Subsea M10 Coupling Tube allows external mounting of this depth sensor when bulkhead access is limited. It provides internal space for wiring and can be sealed with epoxy for waterproofing and strain relief. Ideal for modular ROV or AUV layouts using standard M10×1 threads.

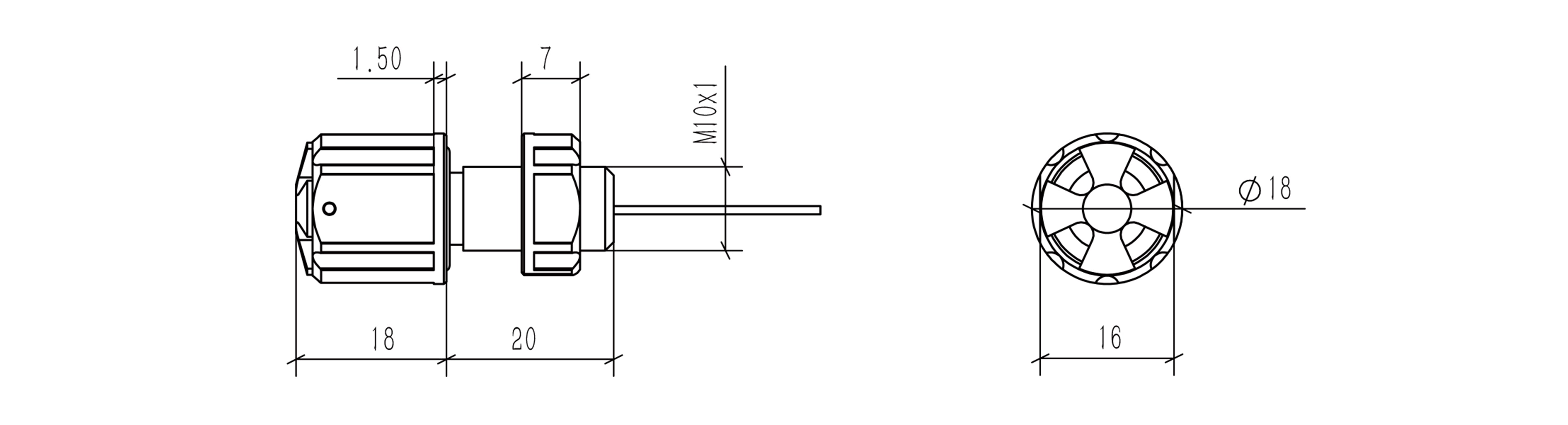

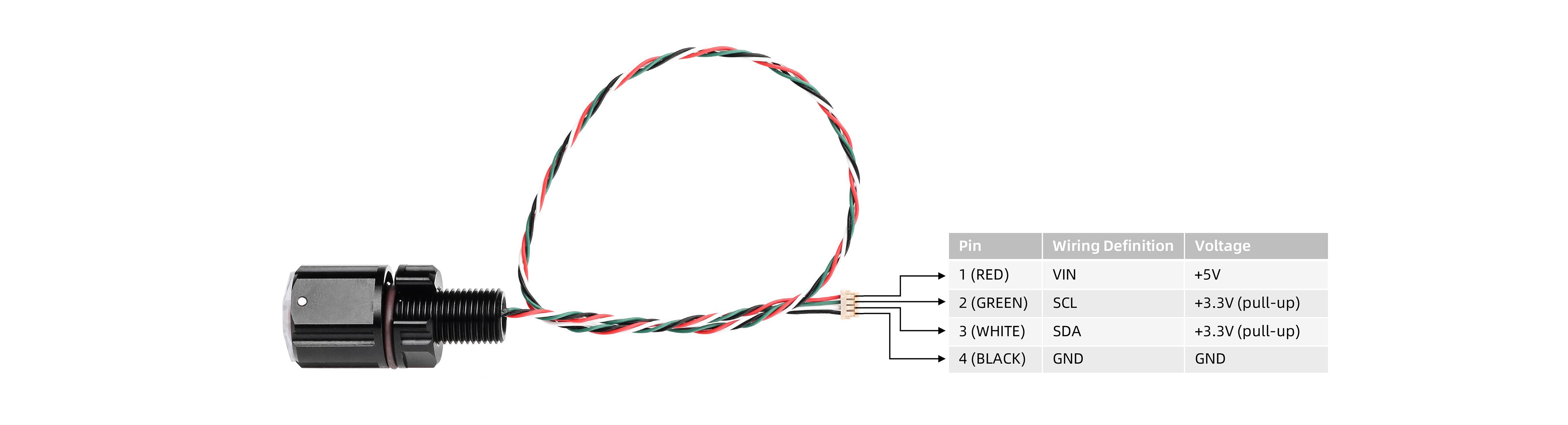

| Specification | Subsea M10 Depth Sensor (0–30 Bar / 0–300 m) |

|---|---|

| Material | Aluminum, Black Anodized |

| Thread | M10 × 1 |

| Voltage | 5 V |

| Peak Current | 1.5 mA |

| Communication | I²C (IIC) |

| I²C Logic Voltage (SDA/SCL) | 3.3 V |

| I²C Address | 0x76 (1110110 b) |

| Wiring Definition |

Red: VIN Green: SCL White: SDA Black: GND |

| Connector Type | DF13-4S-1.25C |

| Wire Length | Approx. 300 mm |

| Operating Pressure | 0–30 Bar |

| Operating Depth | 0–300 m |

| Overpressure | 50 Bar |

| Pressure Resolution | 0.2 mbar |

| Relative Accuracy | ±200 mbar |

| Operating Temperature | –20 ~ 85 °C |

| Temperature Accuracy | ±4 °C (0–60 °C) |

| Sensor Chip | MS5837-30BA |

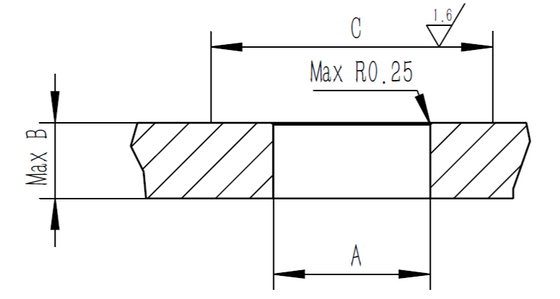

| Recommended Size | M10 Depth Sensor |

|---|---|

| Recommended Bulkhead Through Hole Size (A) | Ø10.1 ± 0.1 |

| Hatch Cover Thickness (B) | 13 mm |

| Surface Range (C) | 20 mm |

Can the wire be extended?

Yes, but care must be taken with I²C communication. Excessively long wires or shared buses may disrupt timing. This can be mitigated by using stronger pull-up resistors or incorporating an I²C relay/repeater chip.

How do I read data without using ArduSub? Are code examples available?

The sensor chip is widely adopted and well-documented. Numerous open-source code examples are available online for integrating the sensor into custom systems.

How should I clean the protective cover after removing it?

Rinse gently using warm or room-temperature water. Do not spray water directly or touch the white soft membrane during cleaning.

What if the white soft membrane is damaged?

If the membrane is punctured or broken, the sensor should no longer be used. Its waterproof integrity and accuracy may be compromised.

Can it be used in seawater and freshwater?

Yes. The sensor is designed for reliable operation in both seawater and freshwater environments.

What are the advantages compared to other manufacturers?

• High reliability: Built to strict design specifications for pressure sensor performance and long-term durability.

• Easy maintenance: The removable protective cover allows quick inspection and cleaning while protecting the delicate sensor membrane from debris like sand and grit.

Can the sensor be used without mounting it to an end cap?

Yes. The sensor can be fully submerged if properly sealed. For guidance, refer to the documentation on waterproofing penetrator-style devices.