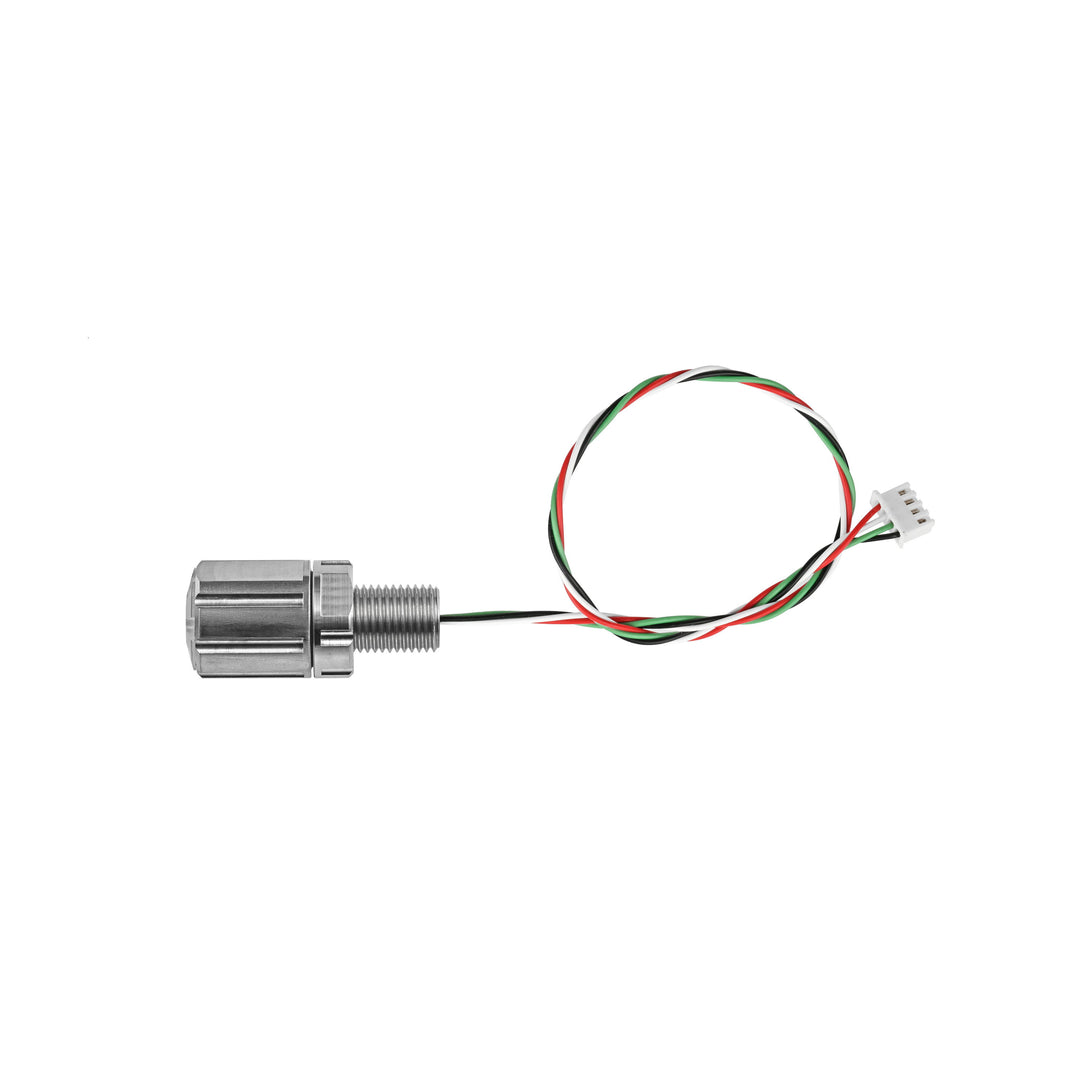

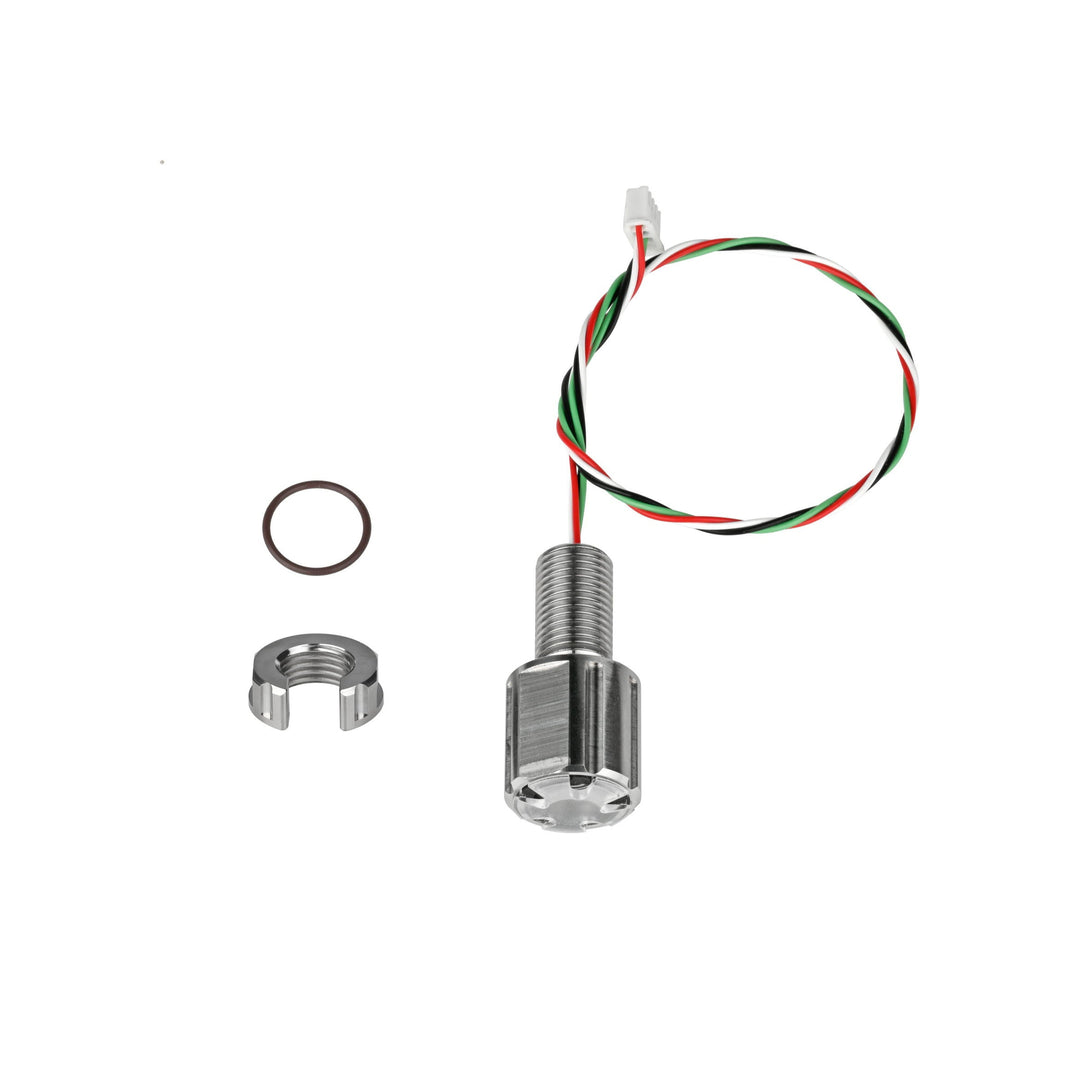

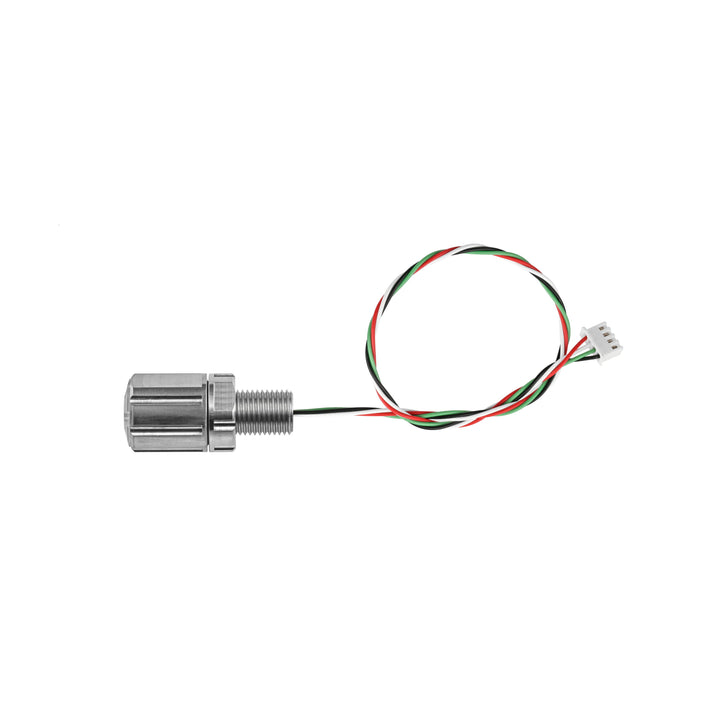

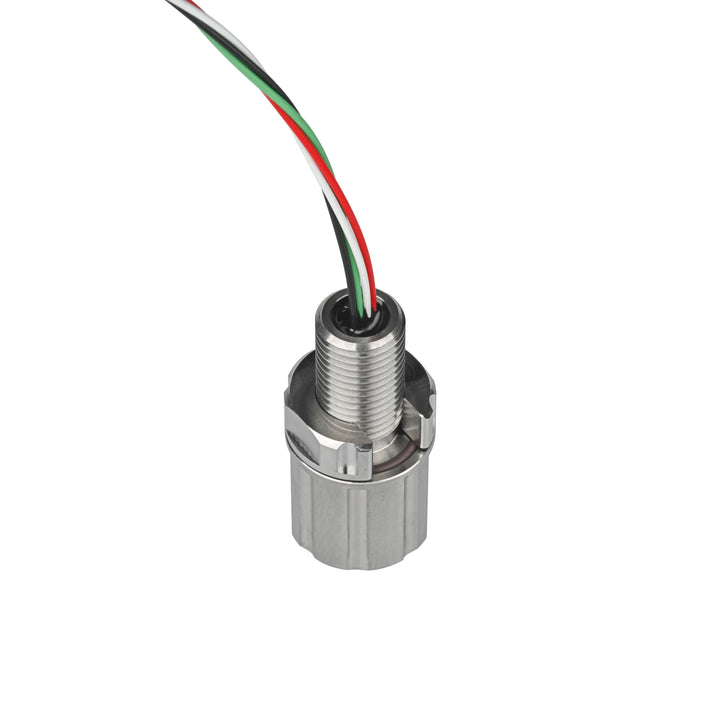

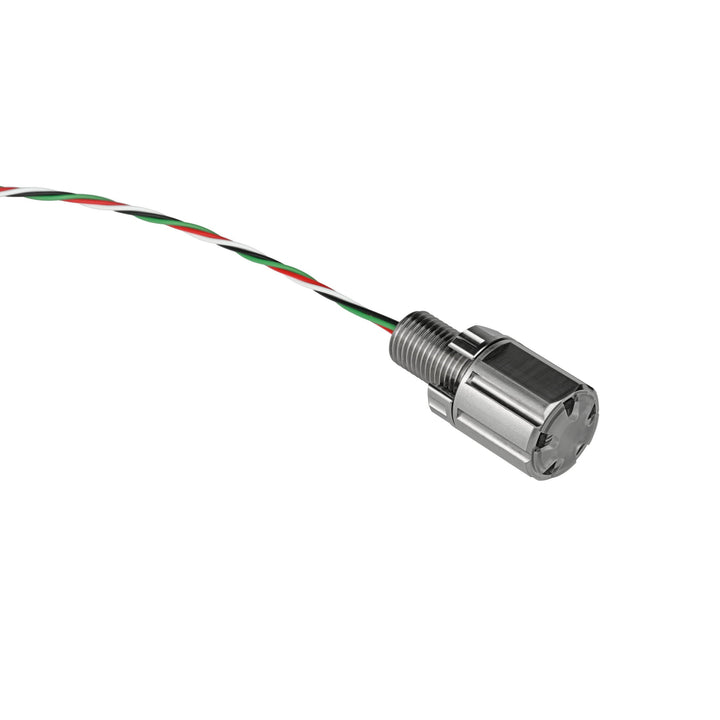

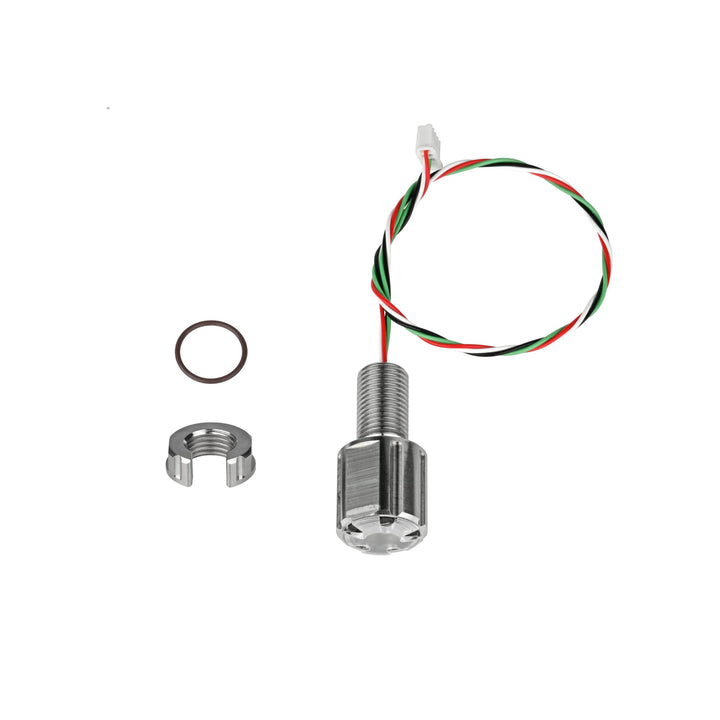

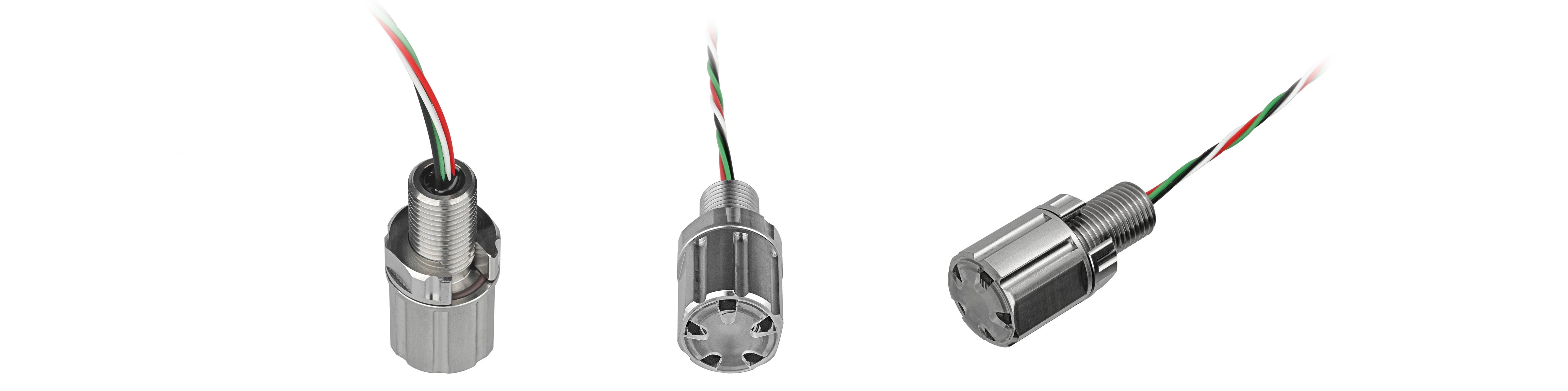

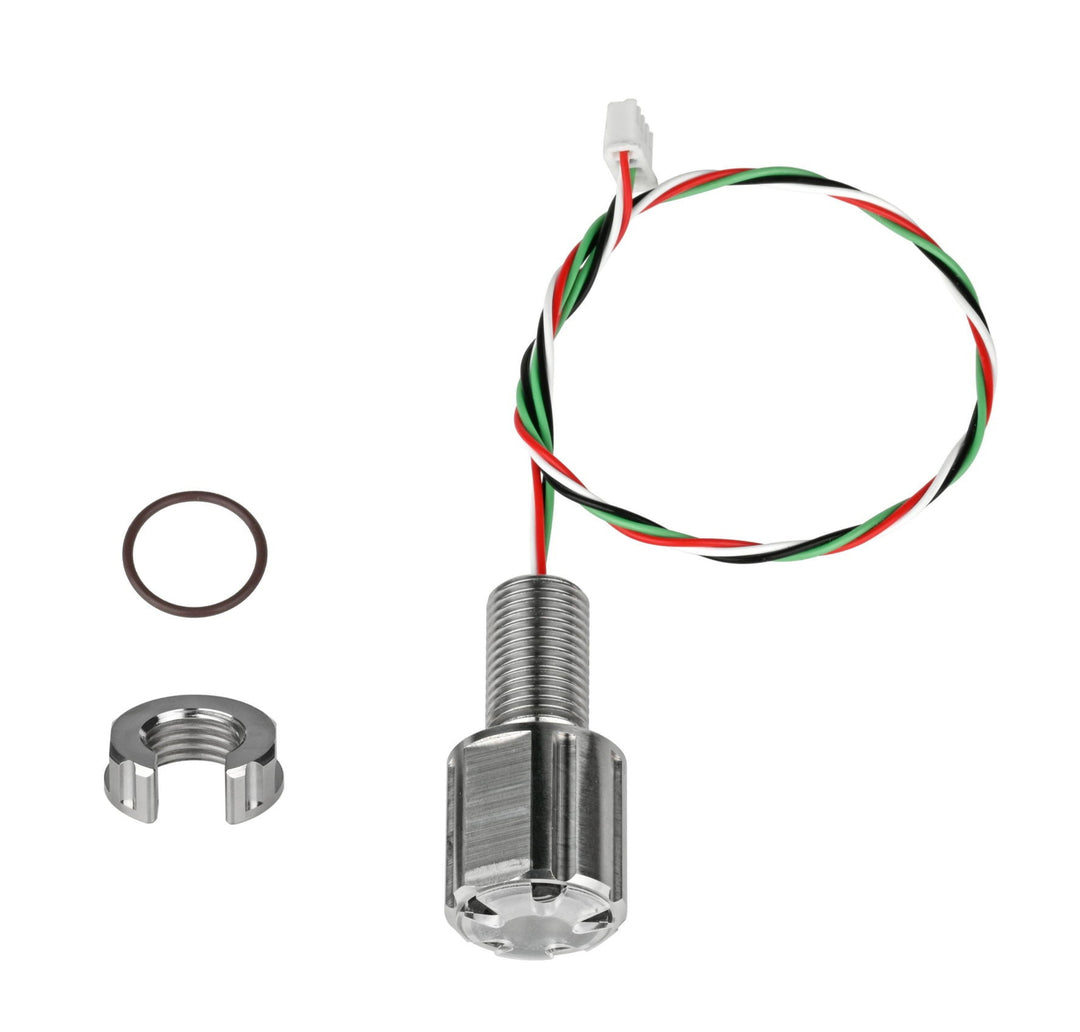

The Subsea M14 Metal Diaphragm Depth Sensor is engineered for long-term submersion and durability in demanding underwater environments. It features a rugged stainless steel diaphragm that transmits external water pressure to the internal sensing circuit via a filled silicone oil chamber. This construction enables maintenance-free operation without the need for daily drying—ideal for continuous-deployment scenarios.

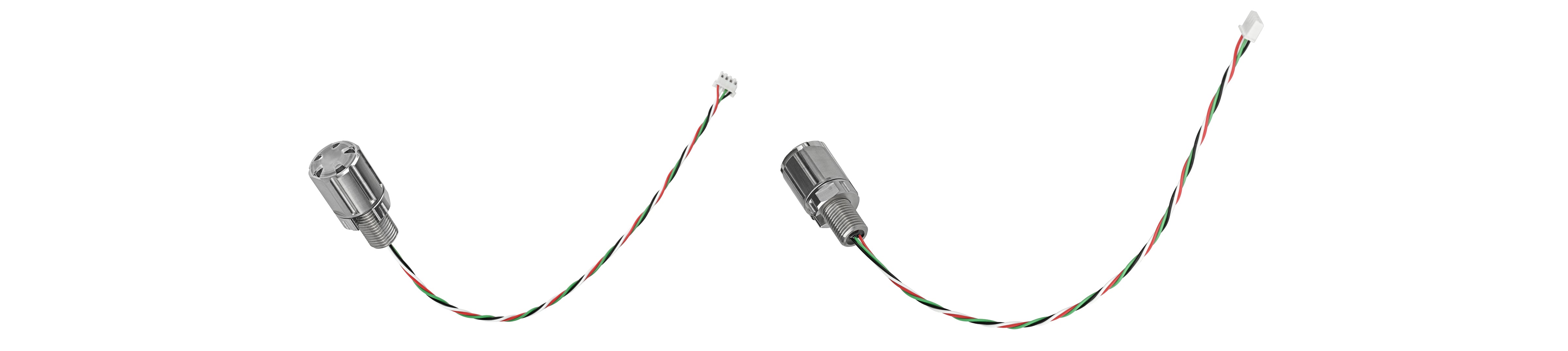

At its core is an integrated solver board that gathers 24-bit pressure and temperature data, applies temperature compensation, and outputs solved depth and temperature readings in real time. These outputs are transmitted via a serial interface using TTL-level USART communication (5 V logic, 115200 bps). Unlike I²C-based depth sensors that interface directly with Pixhawk or similar ArduSub systems, this sensor communicates over UART and requires a microcontroller or companion computer capable of reading TTL serial data. A standard 4-pin XH2.54 connector and 300 mm pigtail are included for straightforward integration.

This architecture offers enhanced accuracy and reliability, especially for high-pressure or long-duration use cases where robustness is critical. The sealed internal oil and diaphragm design also insulates the sensing elements from physical contamination or salinity drift. For applications where high durability and no daily maintenance are priorities, this sensor provides a robust upgrade path compared to more compact I²C-based options.

Sold Separately

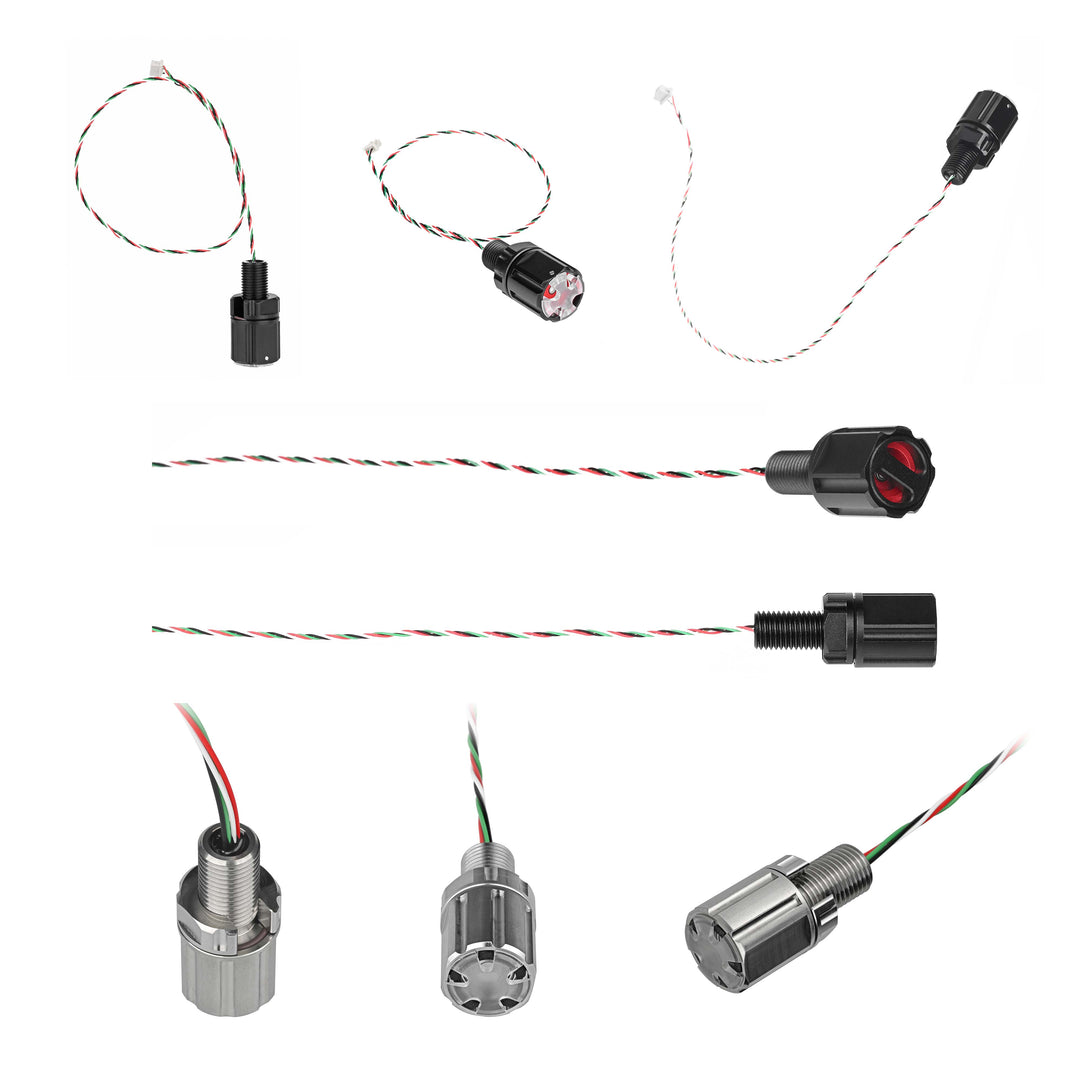

This sensor is ideal for long-term submersion and high-reliability applications. For compact, cost-effective deployments, two other Blu-Sub depth sensors are available using the MS5837 chip platform.

Subsea M8 Depth Sensor (0–30 Bar)

Ultra-compact I²C-based depth sensor with a fixed protective cap and M8 threaded body, designed for Pixhawk/ArduSub integration in space-constrained systems.

Subsea M10 Depth Sensor (0–30 Bar)

Mid-size I²C-compatible sensor with a removable protective cap and M10 threaded housing, ideal for modular builds and easy maintenance access.

Sold Separately

The Subsea M14 Metal Diaphragm Depth Sensor installs into a variety of Blu-Sub subsea enclosures using an appropriately sized M14 mounting hole. Each housing must provide proper sealing, bulkhead thickness, and internal clearance for the sensor body and wiring.

Subsea Watertight Enclosure Box

Compact aluminum enclosure rated to 300 m, pre-drilled with twenty M10 ports—ideal for M10 sensors, indicators, or switches. To install an M14 sensor, custom drilling is required.

Subsea Enclosure Acrylic Tube

Transparent cast acrylic body rated to 250 m, compatible with Blu-Sub aluminum end-caps. Choose end-caps with a properly sized M14 hole for secure sensor mounting and sealing.

Subsea Enclosure Aluminum Tube

Rugged aluminum enclosure rated to 1,000 m. Use with matching aluminum end-caps drilled for an M14 hole to support the depth sensor. Ideal for long-term or deep-water deployments.

| Specification | M14 Depth Sensor |

|---|---|

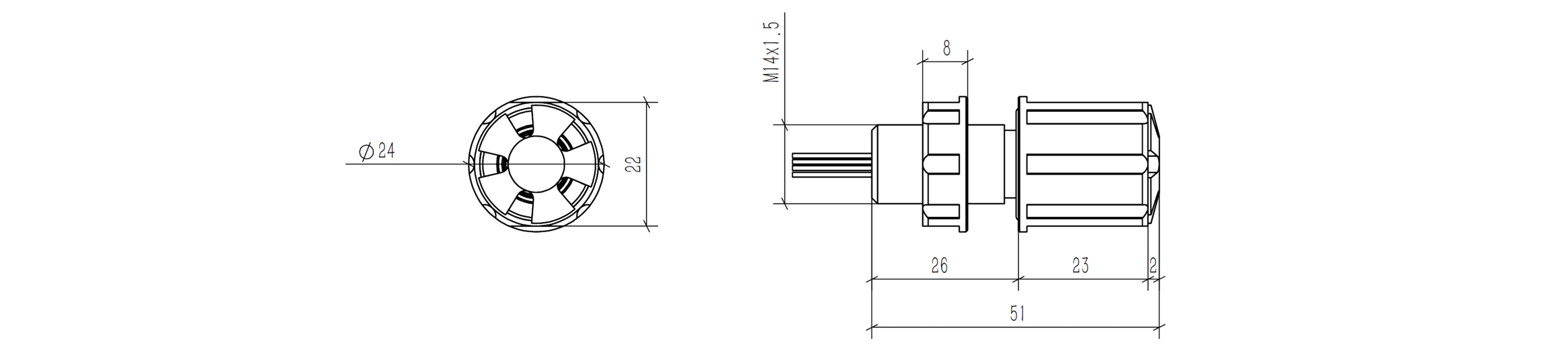

| Thread | M14 × 1.5 |

| Material | Stainless Steel |

| Voltage | 5 V |

| Rated Current | 20 mA |

| Communication Mode | USART (TTL) |

| Baud Rate | 115200 |

| Pressure Range | 0–35 Bar |

| Overpressure | 2 × Pressure Range |

| Intrinsic Error | ±0.2% FS (±0.72 m) |

| Total Error Range | ±1% FS (3.6 m) |

| Operating Temperature | -10 ~ 80 ℃ |

| Temperature Accuracy | ±2 ℃ |

| Wire Length | Approx. 300 mm |

| Connector Type | XH2.54–4Pin |

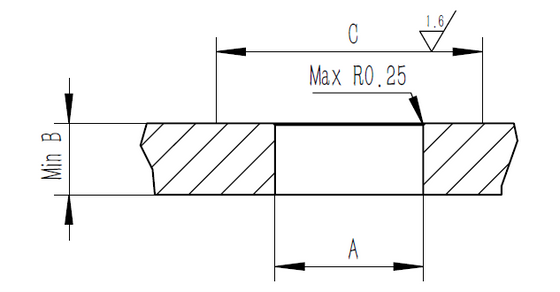

| Recommended Size | M14 Depth Sensor |

|---|---|

| Recommended Bulkhead Through Hole Size (A) | Ø14.1 ± 0.1 |

| Hatch Cover Thickness (B) | 18 mm |

| Surface Range (C) | 26 mm |

| Label | Wire | Name | Function Description |

|---|---|---|---|

| 1 | Red | + | Power supply positive (5 Vdc) |

| 2 | White | TX | Serial port transmit (TXD) |

| 3 | Green | RX | Serial port receive (RXD) |

| 4 | Black | - | Power supply negative (GND) |

- Communication Interface: TTL

- Baud Rate: 115200bps (fixed)

- Data Bits: 8

- Stop Bits: 1

- Parity Bit: None

| External Controller | M14 Depth Sensor |

|---|---|

| 5V | 5V |

| RXD | TXD |

| TXD | RXD |

| GND | GND |

- Connect the sensor to the controller and apply power (5 V).

- Ensure TX and RX lines are connected properly.

- Upon successful connection, the sensor outputs real-time depth and temperature data.

The sensor outputs a string:

T=XX.XXD=XX.XX\r\n- T: Temperature in degrees Celsius (°C)

- D: Depth in meters (m)

\r\n: End of each data line- Example:

T=25.27D=1.21means 25.27 °C and 1.21 m

| Serial Command | Description | Default Value |

|---|---|---|

!Fxxxx\r\n |

Set the sensor to calculate with a specific density value. "xxxx" represents the set liquid density. Freshwater: 997 kg/m³ | Saltwater: 1029 kg/m³ |

997 |

!Dxx.xx\r\n |

Reserved command for depth output offset adjustment. "xx.xx" is a floating-point offset. |

0 |

!Txx.xx\r\n |

Reserved command for temperature output offset adjustment. "xx.xx" is a floating-point offset. |

0 |

!!\r\n |

Pause sensor output. Serial port outputs all parameters. | None |

!R\r\n |

Reset the calculation board. | None |

!r\r\n |

Restore all initial settings. | None |

!C\r\n |

Clear all offset settings. | None |

!!\r\n):FluidDensity: 997

Doffset: 0.00

Toffset: 0.00

!D0.55applied to a measured value of -0.55 → Output = 0.00!D-0.10applied to a measured value of 0.10 → Output = 0.00!T1.00applied to 25.00 °C → Output = 26.00 °C!T-1.00applied to 25.00 °C → Output = 24.00 °C

The sensor captures depth and temperature with high accuracy. After power-on reset, the initial air depth reading can be used as a zero offset and applied to future underwater measurements. This effectively zeroes the depth reading relative to the air baseline.

Temperature calibration is not built-in but can be corrected using

!Txx.xx\r\n by referencing a known external temperature source.

Is there a built-in solver board?

Yes. The sensor contains an internal solver board that captures 24-bit pressure and temperature data, applies temperature compensation, and outputs real-time depth and temperature readings over a TTL serial interface.

Can the wires be extended?

The sensor uses TTL serial communication, which is not ideal for long cable runs. If extended wiring is needed, use a level shifter to convert to RS-232 or RS-485 to reduce bit error rate (BER).

Does the sensor require calibration? What data is output from the serial port?

The sensor outputs depth and temperature values directly over serial. Calibration can be done at the surface if needed, but the output is already processed and requires no additional decoding or compensation.

What if the metal diaphragm is scratched or dented?

If the diaphragm is deformed—such as from wrench damage or pitting—it should not be used, as this may compromise both data accuracy and sealing integrity.

Can I apply pressure with my finger to test the sensor?

No. Manual pressure is uneven and may deform the sensitive metal diaphragm, especially with fingernails. Avoid any direct pressure testing.

Is it directly compatible with ArduSub?

No, the sensor uses TTL serial output and is not plug-and-play with ArduSub systems. Integration requires custom firmware or additional interfacing.