Blu-Sub Cable Penetrators are specialized bulkhead-style fittings used to feed electrical cables into and out of pressure-sealed underwater enclosures. Designed for watertight integrity and mechanical reliability, each penetrator includes a central bore for threading cables and a matching nut to lock the unit in place. The design supports both flat surface installations and end-cap interfaces.

For optimal sealing, a marine-grade epoxy such as Loctite Epoxy Marine is recommended. In non-load-bearing applications, sulfur-based adhesives like 3M2131 may be used as an alternative.

An open-end nut is included with each penetrator to assist with cable threading, alignment, and secure fitting. The nut is designed to be tightened with a standard wrench, and the bulkhead body includes a raised step to help prevent wrench damage to enclosure surfaces. In cramped spaces where traditional tools won’t fit, snap ring pliers may be used to rotate the head via its semi-circular groove.

To enhance mechanical stability and prevent loosening under vibration or pressure, use a washer or anti-slip pad between the nut and the bulkhead wall. Avoid friction-reducing materials like rubber gaskets on the nut side, as they may compromise the seal. If additional thread locking is needed, apply Loctite Threadlocker sparingly, ensuring it does not come into contact with the O-ring or sealing surfaces.

These cable penetrators are fully compatible with Blu-Sub end caps and subsea enclosures, using standard metric thread sizing. Each penetrator is sold individually and requires sealing by the user before underwater deployment.

Deep-Sea Cable Penetrator Compatibility Guide:

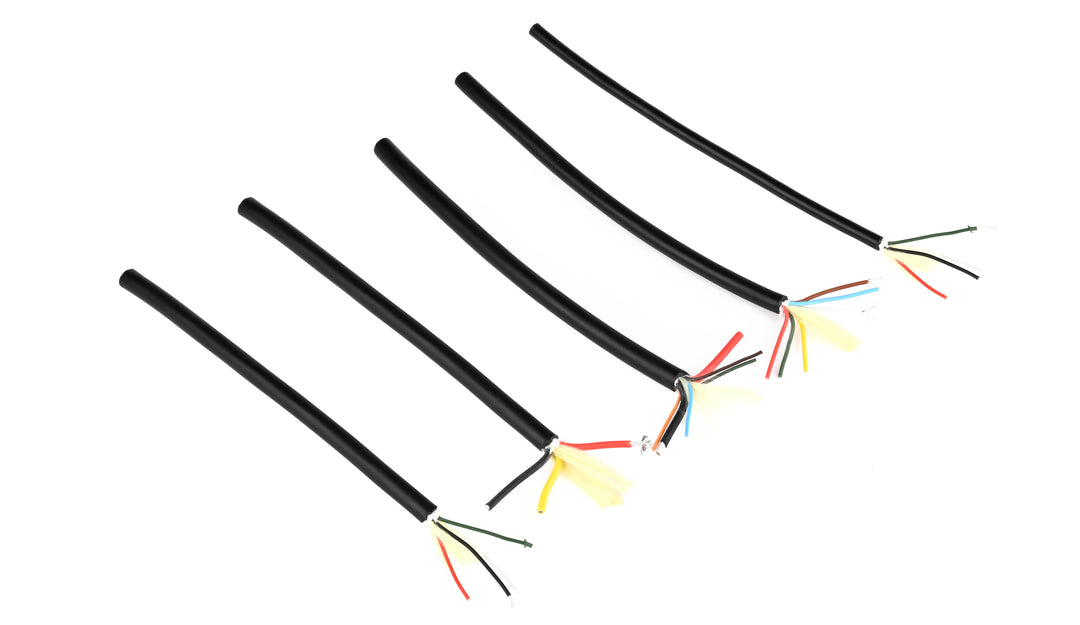

| Deep-Sea Underwater Cable | 3-Core (16AWG) BS-SSC-3CORE-BLK-16A1 |

6-Core (24AWG) BS-SSC-6CORE-BLK-24A1 |

4-Core (28AWG) BS-SSC-4CORE-BLK-28A1 |

6-Core (2x16 / 4x26AWG) BS-SSC-6CORE-BLK-MXA1 |

4-Core (2x24 / 2x26AWG) BS-SSC-4CORE-BLK-MXA1 |

3-Core (20AWG) BS-SSC-3CORE-BLK-20A1 |

|---|---|---|---|---|---|---|

| Compatible Deep-Sea Cable Penetrator | M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-08A1 |

M6x1 Aluminum BS-SSC-CBLPN-BLK-06A1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

M10x1 Aluminum BS-SSC-CBLPN-BLK-10A1 |

M8x1 Aluminum BS-SSC-CBLPN-BLK-08A1 |

Sold Separately

Blu-Sub offers a range of cable penetrators to meet different installation methods, enclosure types, and underwater depth requirements:

Deep-Sea M10 Gland Cable Penetrators – Threaded M10 design with a compression gland for removable, modular sealing. Ideal for deepwater enclosures requiring strain relief. Depth Rating: Up to 1,000 m / 3,281 ft

Low-Depth M10 Gland Cable Penetrators – A compact and cost-effective solution for shallow water and low-pressure systems. Depth Rating: Up to 100 m / 328 ft

Mid-Depth M8 Gland Cable Penetrators – Slim-profile gland suitable for tight mounting areas or small form-factor enclosures. Depth Rating: Up to 300 m / 984 ft

Sold Separately

Subsea Aluminum End-Cap

Select models feature pre-drilled ports or blank positions that can be tapped or drilled to accommodate various penetrator thread sizes (e.g., M6, M8, M10).

Subsea Polymer Flange & End-Cap

Can be easily user-drilled to support different Blu-Sub penetrator sizes, making it ideal for custom shallow-water assemblies.

Subsea Watertight Enclosure Box

Includes 20 pre-drilled M10 ports for fast integration of cable penetrators, connectors, and sensors in a sealed box configuration.

Subsea M10 Coupling Tube

Designed for in-line cable splicing and external mounting of penetrator-based devices such as signal indicators, sensors, or switches. One end features a single M10 threaded port, with the interior cavity used for sealing and strain relief.

| Bulkhead Size | Material | Appearance | O-ring Size (mm) | O-ring Material |

|---|---|---|---|---|

| M6x1 Cable Penetrator | 6061 Aluminum | Black Anodized | Ø7 x 1.5 | FKM75 Brown Fluorine Rubber |

| M8x1 Cable Penetrator | 6061 Aluminum | Black Anodized | Ø10 x 1.5 | FKM75 Brown Fluorine Rubber |

| M10x1 Cable Penetrator | 6061 Aluminum | Black Anodized | Ø12 x 1.5 | FKM75 Brown Fluorine Rubber |

| M14x1.5 Cable Penetrator | 6061 Aluminum | Black Anodized | Ø17 x 1.5 | FKM75 Brown Fluorine Rubber |

| M16x1.5 Cable Penetrator | 6061 Aluminum | Black Anodized | Ø20 x 1.5 | FKM75 Brown Fluorine Rubber |

| Performance Characteristics | Cable Penetrator |

|---|---|

| Maximum Rated Depth | Related to actual sealing and scenario / Sample testing up to 1000 meters |

| Design Lifetime | Related to actual sealing and scenario / Sample testing up to 1 year or 100 cycles |

| Temperature Rating (air) | Related to actual sealing and scenario / Samples testing from -25 to 60°C |

| Temperature Rating (water) | Related to actual sealing and scenario / Samples testing from -4 to 40°C |

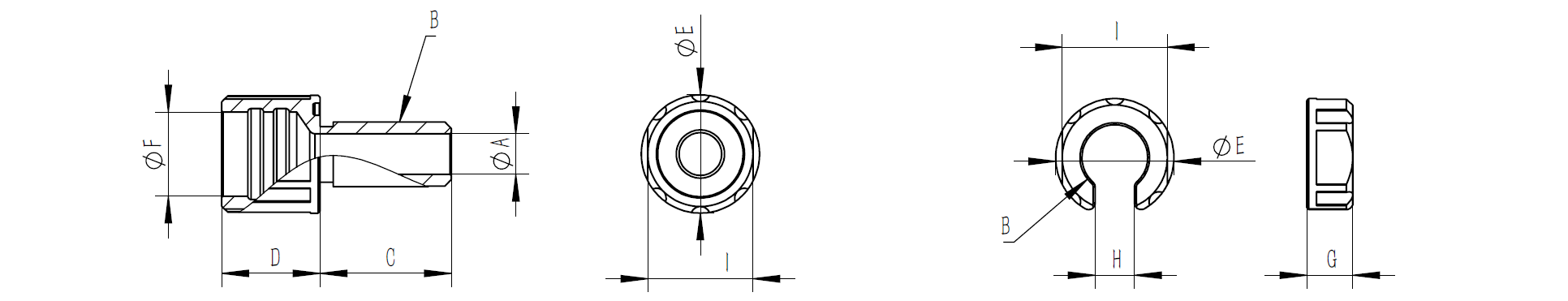

| Bulkhead Size | M6x1 Cable Penetrator | M8x1 Cable Penetrator | M10x1 Cable Penetrator | M14x1.5 Cable Penetrator | M16x1.5 Cable Penetrator |

|---|---|---|---|---|---|

| Seal Sizes (A) | 3.3 | 4.6 | 6.5 | 9 | 11 |

| Bulkhead Thread (B) | M6x1 | M8x1 | M10x1 | M14x1.5 | M16x1.5 |

| Bulkhead Thread Length (C) | 10 | 20 | 20 | 26 | 26 |

| Assembled Height from Endcap (D) | 14 | 14 | 15 | 18 | 18 |

| Overall Outer Diameter (E) | 13 | 15 | 18 | 24 | 30 |

| Inner Bore Diameter (F) | 9 | 10 | 13 | 19 | 23 |

| Nut Height (G) | 4 | 6 | 7 | 8 | 9 |

| Nut Slot Width (H) | 3.5 | 4.5 | 6 | 9 | 10 |

| Width between Opposite Sides of Wrench Groove (I) | 12 | 13 | 16 | 22 | 27 |

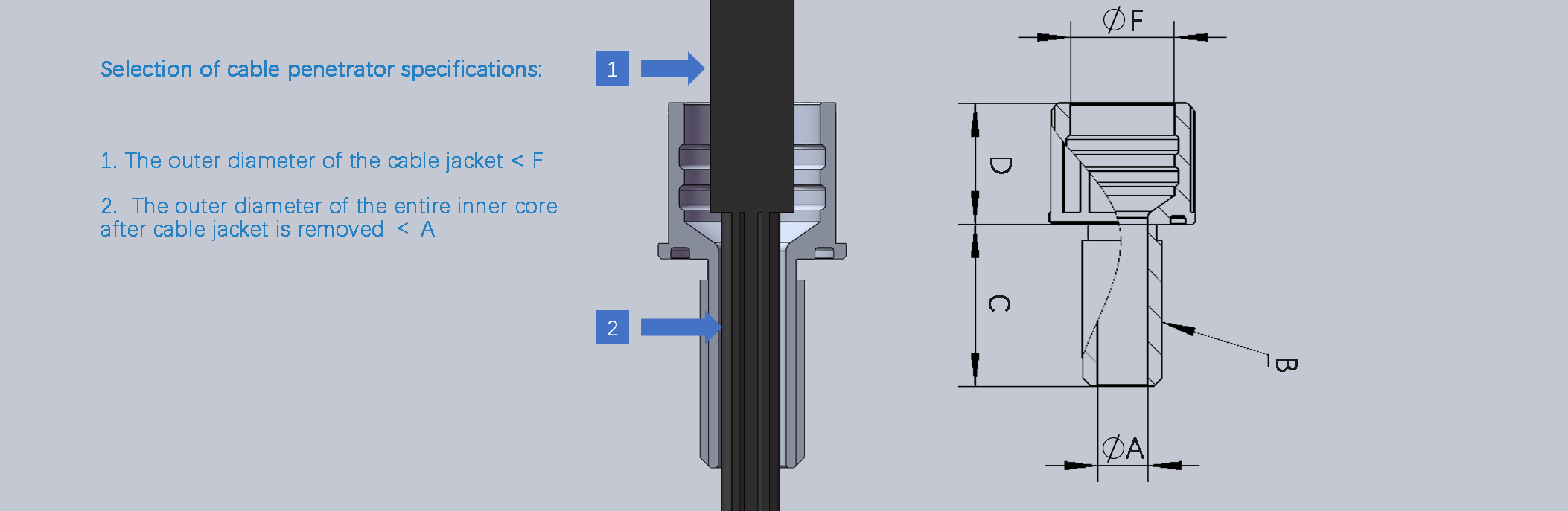

| Recommended Size | M6x1 Cable Penetrator | M8x1 Cable Penetrator | M10x1 Cable Penetrator | M14x1.5 Cable Penetrator | M16x1.5 Cable Penetrator |

|---|---|---|---|---|---|

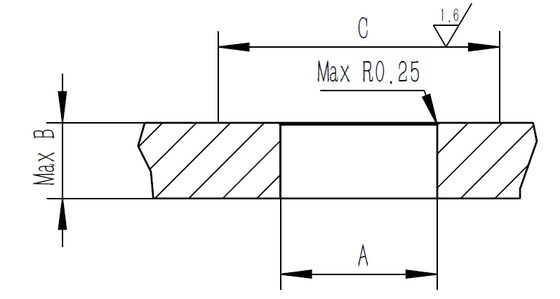

| Recommended Bulkhead Through Hole Size (A) | Ø6.1 ± 0.1 | Ø8.1 ± 0.1 | Ø10.1 ± 0.1 | Ø14.1 ± 0.1 | Ø16.1 ± 0.1 |

| Hatch Cover Thickness (B) | 6 mm | 14 mm | 13 mm | 18 mm | 17 mm |

| Surface Range (C) | 15 mm | 17 mm | 20 mm | 26 mm | 32 mm |

What type of sealing material is recommended?

For strong, permanent seals, use epoxy resin such as Loctite Epoxy Marine. For non-load-bearing or removable installations, sulfur-based adhesives like 3M2131 are also suitable.

How do I install or remove the cable penetrator?

Use a wrench on the flat sides of the bulkhead for proper torque. If the workspace is tight, you can use snap ring pliers to engage the semi-circular groove at the head for positioning or adjustment.

Do I need to apply thread locker?

Applying Loctite thread locker between the nut and the bulkhead is recommended to prevent loosening. Be careful not to let thread glue contact the O-ring or sealing surface.