Low-Depth M10 Gland Cable Penetrator is a compact, cost-effective sealing solution engineered for underwater cable pass-through applications at depths up to 100 meters (328 feet). It uses o-rings and mechanical compression to form a watertight seal around the cable sheath, enabling safe and reliable cable entry into shallow subsea enclosures.

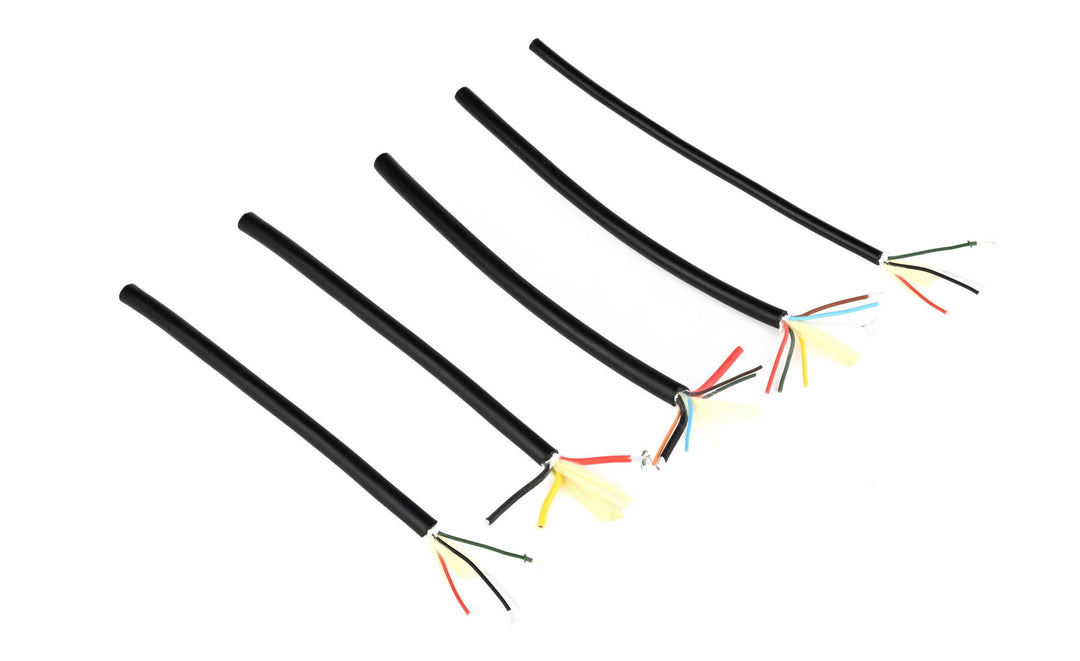

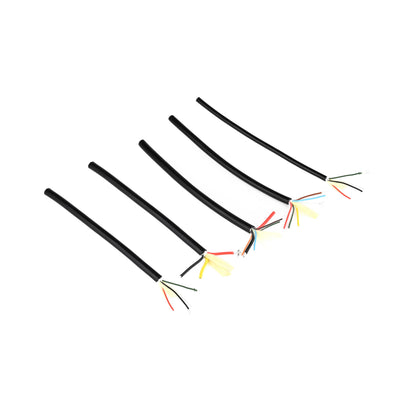

While optimized for Deep-Sea Underwater Cable, this penetrator can also accommodate many third-party subsea cables from other manufacturers. A compatibility guide is provided below to assist with model selection based on cable diameter. Please refer to this guide and contact us if you require support. We can also assist with special requirements or develop custom-sized components as needed.

This low-depth model offers a more economical alternative to Deep-Sea M10 Gland Cable Penetrators, which are pressure-rated between 300 to 1,000 meters. The Low-Depth version is ideal for sensor housings, ROVs, inspection systems, and other shallow-water applications requiring secure and waterproof cable access.

Compatibility Chart for Low-Depth M10 Gland Cable Penetrator with Deep-Sea Cable:

| 3-Core (16AWG) BS-SSC-3CORE-BLK-16A1 |

6-Core (24AWG) BS-SSC-6CORE-BLK-24A1 |

4-Core (28AWG) BS-SSC-4CORE-BLK-28A1 |

6-Core Mixed (2x16AWG / 4x26AWG) BS-SSC-6CORE-BLK-MXA1 |

4-Core Mixed (2x24AWG / 2x26AWG) BS-SSC-4CORE-BLK-MXA1 |

3-Core (20AWG) BS-SSC-3CORE-BLK-20A1 |

|---|---|---|---|---|---|

|

7.8 × 5.6 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BRA1 |

7.2 × 4.6 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BRA2 |

5.6 × 3.4 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BLA1 |

8.4 × 5.9 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BRA3 |

7.8 × 4.1 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BRA4 |

6.4 × 4.3 Copper (Nickel-Plated Brass) BS-SSC-GLPEN-NPB-BLA2 |

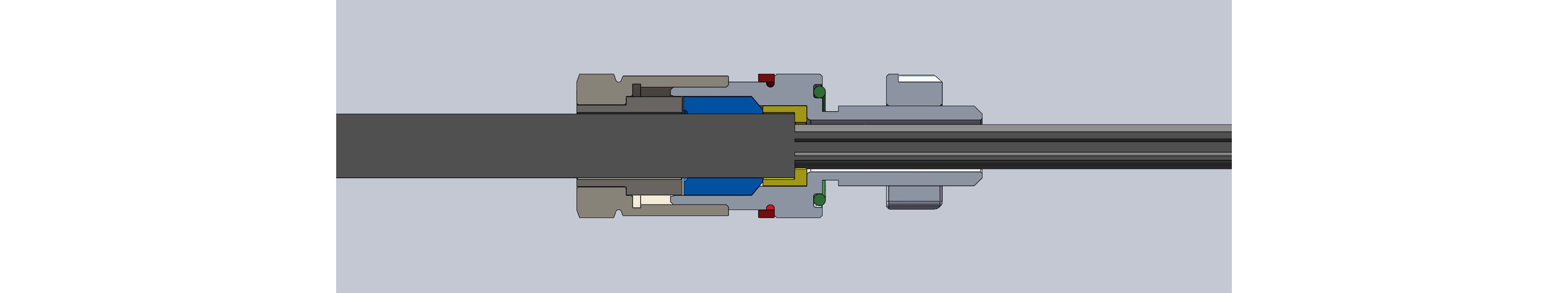

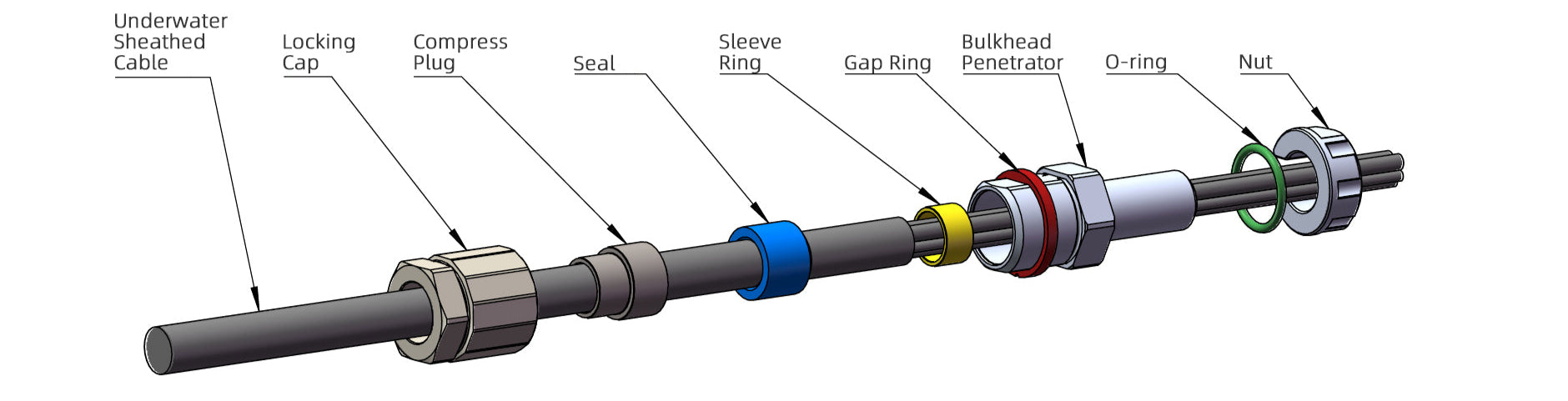

Seal Construction Theory:

The sealing mechanism uses a split compression plug and a sleeve ring, which are pressed inward by the locking cap to deform and expand the sealing element both radially and axially. This forms a watertight grip around the cable sheath while locking it mechanically into place. When the locking cap is properly tightened, the seal compresses until the cable sheath exhibits a visible reduction in diameter—indicating a secure hold and resistance to cable pullout. As external pressure increases with submersion, the cable sheath compresses inward, forcing the sealing sleeve to press more firmly into the beveled interior of the penetrator, enhancing the watertight seal under pressure.

Each penetrator model is supplied with a matched set of components: locking cap, split compression plug, sleeve ring, and sealing ring. These parts are tailored to accommodate different cable sheath diameters and wall thicknesses. The internal bore of the sleeve ring is sized to the cable's minimum sheath diameter, preventing pressure-driven cable migration. The split design of the compression plug ensures even sealing and prevents twisting or displacement during tightening. Optional custom sleeve rings may be used to reduce cost by integrating the sleeve directly into the penetrator body.

The thickness of the gap ring (washer) determines the depth of thread engagement, the compression pressure applied by the locking cap, and the final sealing force. It is important to follow the recommended gap ring thickness to ensure proper installation and consistent waterproofing performance.

Sold Separately

Low-Depth M10 Gland Cable Penetrators are designed to create a watertight seal around compatible Blu-Sub Deep-Sea Cables using a compression-based locking system. A compatibility guide is provided above to help identify which cable types are supported. These penetrators are also suitable for use with third-party cables—refer to the specifications for dimensional guidance, and feel free to contact us to confirm compatibility.

Blu-Sub offers several alternative cable penetrators for subsea power and communication cables, each suited for different installation and depth requirements:

Deep-Sea Cable Penetrators – Epoxy-sealed design ideal for permanent, high-pressure installations. Depth Rating: Up to 1,000 m / 3,281 ft

Deep-Sea M10 Gland Cable Penetrators – Similar threaded format with a longer body and robust strain relief for deepwater modular housing. Depth Rating: Up to 1,000 m / 3,281 ft

Mid-Depth M8 Gland Cable Penetrators – Slimmer profile suited for compact enclosures and tight mounting spaces. Depth Rating: Up to 300 m / 984 ft

Sold Separately

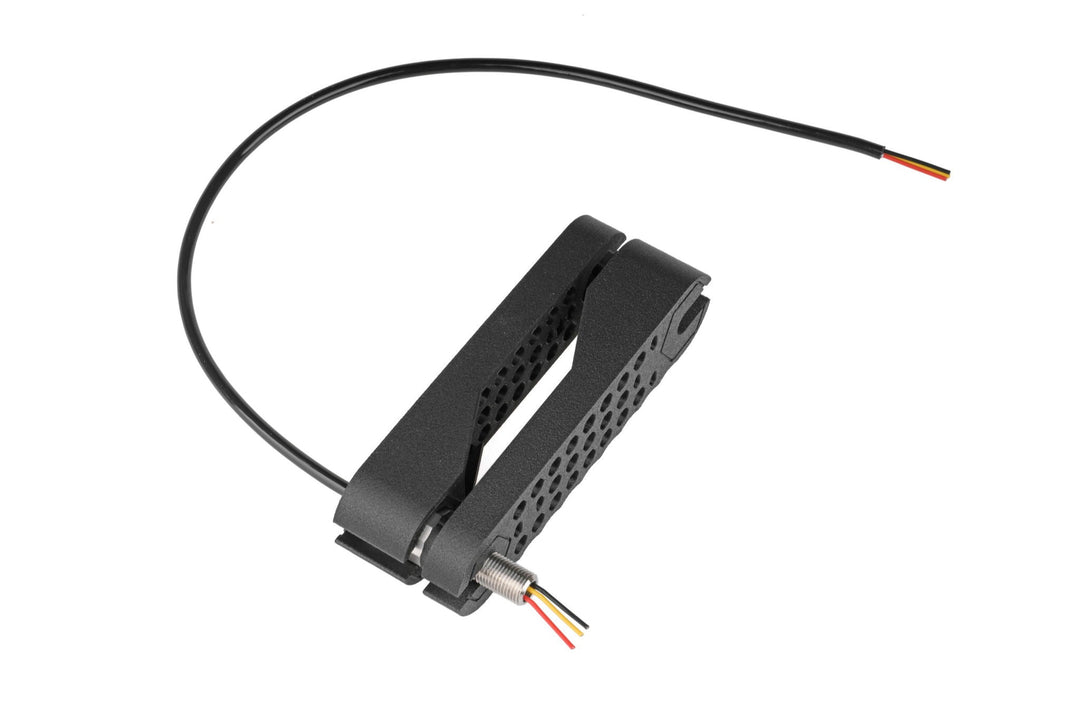

The Scratch-Proof Wrench Tool is designed to fit Blu-Sub Low-Depth M10 Gland Cable Penetrators, enabling safe and accurate installation without damaging the gland body. It is strongly recommended when working with copper and aluminum penetrators to avoid surface scratches and ensure sealing surfaces remain intact. The tool is also fully compatible with stainless steel versions, though metal wrenches may be used if preferred. Two tools are required to achieve proper alignment and sealing pressure during assembly.

Sold Separately

Subsea Aluminum End-Cap

Select versions include unthreaded M10 holes or blank positions that can be drilled to accept the Low-Depth M10 Gland Cable Penetrator. Installed using a rear locking nut to ensure a watertight seal.

Subsea Polymer Flange & End-Cap

User-drillable to accept M10 penetrators. Ideal for low-pressure, modular, or surface-rated systems requiring flexible cable access with secure sealing.

Subsea Watertight Enclosure Box

Pre-configured with 20 unthreaded M10 ports, allowing direct installation of Low-Depth M10 Gland Cable Penetrators using standard rear locking nuts for pressure-rated entry.

Subsea M10 Coupling Tube

Enables an inline sealed feedthrough using a single M10 threaded port. Compatible with the Low-Depth M10 Gland Cable Penetrator and includes an internal cavity for protected splices or terminations.

| Item | Main Material | Applicable Cable Specifications | Sleeve Ring (A × B) | Compression Plug (A) | Gap Ring Thickness (S) | O-ring | Waterproofing Depth | Weight |

|---|---|---|---|---|---|---|---|---|

|

Subsea M10 Low-Depth Gland Cable Penetrator 7.8 x 5.6 BS-SSC-GLPEN-NPB-BRA1 |

Copper w/ Nickel-Plated Brass |

3x16AWG BS-SSC-3CORE-BLK-16A1 |

7.8 x 5.6 | 7.8 | 3.0 | #3 Brown | 100m | ≈46g |

|

Subsea M10 Low-Depth Gland Cable Penetrator 7.2 x 4.6 BS-SSC-GLPEN-NPB-BRA2 |

Copper w/ Nickel-Plated Brass |

6x24AWG BS-SSC-6CORE-BLK-24A1 |

7.2 x 4.6 | 7.2 | 2.5 | #3 Brown | 100m | ≈46g |

|

Subsea M10 Low-Depth Gland Cable Penetrator 5.6 x 3.4 BS-SSC-GLPEN-NPB-BLA1 |

Copper w/ Nickel-Plated Brass |

4x28AWG BS-SSC-4CORE-BLK-28A1 |

5.6 x 3.4 | 5.6 | 4.0 | #2 Black | 100m | ≈46g |

|

Subsea M10 Low-Depth Gland Cable Penetrator 8.4 x 5.9 BS-SSC-GLPEN-NPB-BRA3 |

Copper w/ Nickel-Plated Brass |

2x16AWG+4x26AWG BS-SSC-6CORE-BLK-MXA1 |

8.4 x 5.9 | 8.4 | 3.5 | #3 Brown | 100m | ≈46g |

|

Subsea M10 Low-Depth Gland Cable Penetrator 7.8 x 4.1 BS-SSC-GLPEN-NPB-BRA4 |

Copper w/ Nickel-Plated Brass |

2x24AWG+2x26AWG BS-SSC-4CORE-BLK-MXA1 |

7.8 x 4.1 | 7.8 | 2.5 | #3 Brown | 100m | ≈46g |

|

Subsea M10 Low-Depth Gland Cable Penetrator 6.4 x 4.3 BS-SSC-GLPEN-NPB-BLA2 |

Copper w/ Nickel-Plated Brass |

3x20AWG BS-SSC-3CORE-BLK-20A1 |

6.4 x 4.3 | 6.4 | 4.5 | #2 Black | 100m | ≈46g |

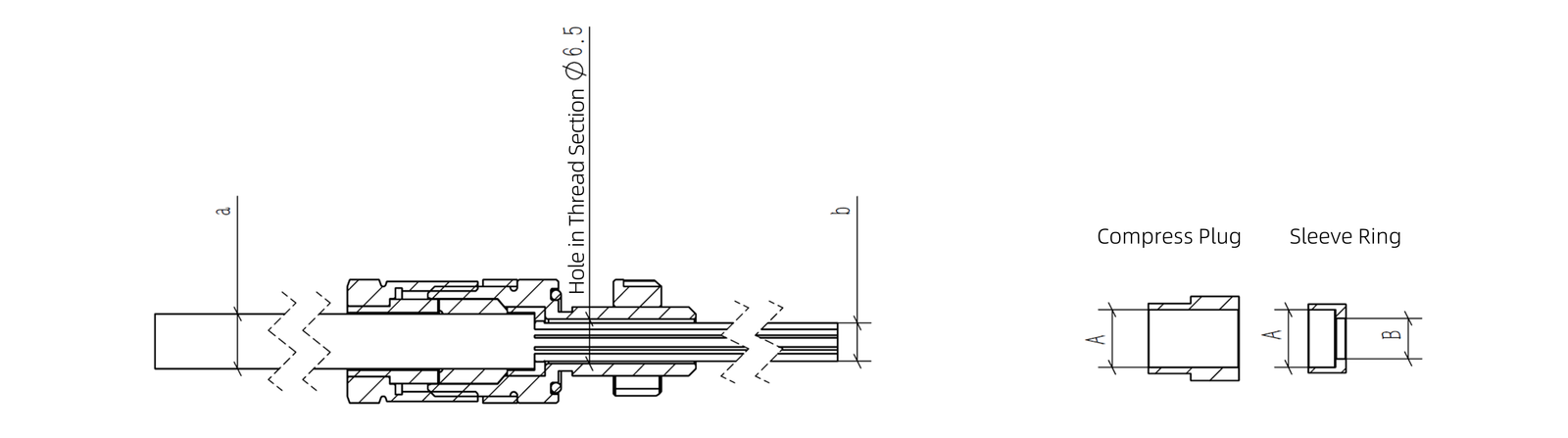

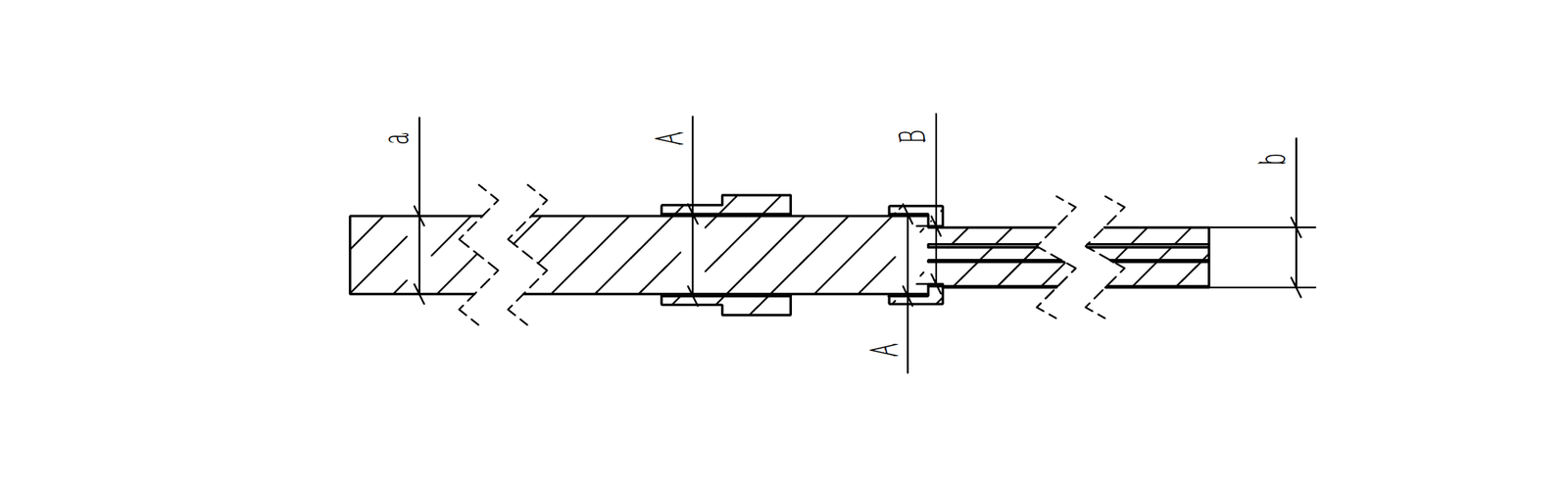

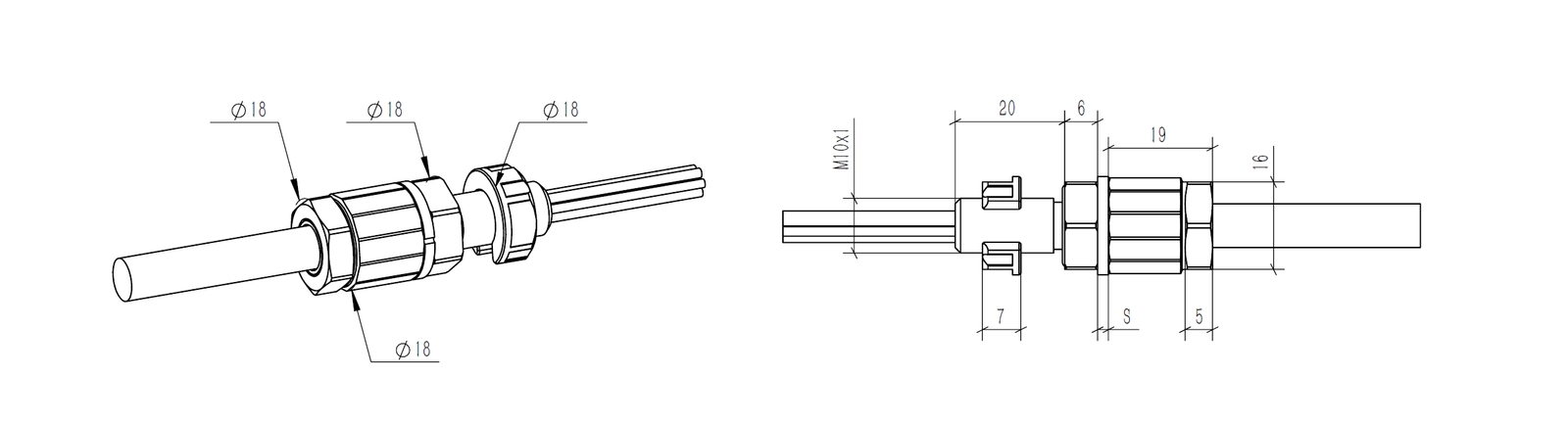

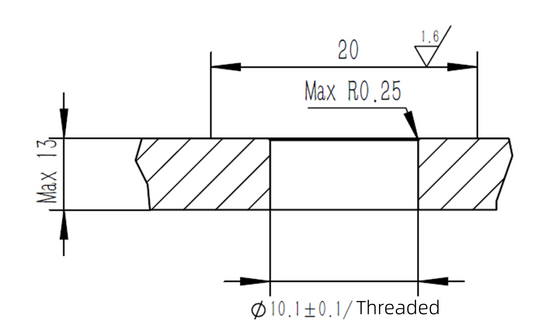

Dimension drawings provided below:

Tip: The surface of the copper gland penetrator will discolor after coming into contact with water. This is a natural result of oxidation, especially in marine or humid environments, and is purely cosmetic. The change in color does not affect sealing performance or structural integrity. See example image below.

To ensure a proper seal, select the correct model by evaluating two cable dimensions:

- Outer diameter (a): The outside of the cable sheath

- Inner diameter (b): The minimum opening required for internal conductors

Compare these to the AxB sleeve ring specs shown in the dimension drawings. A proper fit must meet:

- A ≥ a

- B ≥ b

- (A − a) ≤ 0.8 mm and (B − b) ≤ 0.8 mm

When your cable falls within this range, standard gap rings can be used. Note: sheath material and hardness also affect sealing reliability.

If your cable falls outside these guidelines, we recommend validation testing:

- Pull test to confirm retention

- Pressure test for at least two weeks

- Environmental testing (e.g., thermal cycling or pressure shocks)

Need help? We can support custom sizing. Contact us with your cable specs and reference the dimension drawings above.

Note: In the dimension drawings, "S" refers to the thickness of the gap ring.

Product: Low-Depth M10 Gland Cable Penetrators

Description: Compact, shallow-water-rated gland-style penetrators for M10 threaded ports. These provide a watertight seal for Deep-Sea Cables entering enclosures in low-depth ROV, AUV, or sensor applications.

Installation Guide:

- Cut the cable to the required length. Strip the sheath and core filler at the enclosure end, ensuring a flat cut at the sheath's end.

- Clean the outer jacket of the cable and all gland penetrator components with alcohol and a lint-free cloth.

- Thread the penetrator parts onto the cable in the correct order. Push the cable inward until the shear surface meets the sleeve ring. Hand-tighten the locking cap.

- Use a wrench and vise (or a scratch-proof wrench tool) to tighten the locking cap and penetrator body until snug against the included gap ring. Do not overtighten.

Notes:

- The sheath end must be flat and properly seated against the sleeve ring to ensure sealing.

- All parts—including cable jackets, seals, and penetrator threads—must be thoroughly cleaned with alcohol to remove dust, oil, or other contaminants.

- Aluminum and copper versions should not be clamped with a standard vise or metal wrench. Use a scratch-proof (non-marring) wrench to avoid deformation or surface damage.

- Wrenches may loosen slightly with repeated use. Tighten only until the gap ring is secure—do not overtighten or continue turning once seated.

- During final tightening, apply inward pressure on the cable to keep the shear surface tight against the sleeve ring.

- Tip: The surface of the copper gland penetrator will discolor after coming into contact with water. This is a natural cosmetic change and does not affect performance.

Can the sealing part be disassembled and assembled repeatedly?

It is not recommended to disassemble the sealing section repeatedly. If disassembly is necessary, limit it to no more than two times. Avoid reusing the same section of compressed cable — trim the cable sheath before reinstalling.

How is the waterproof depth guaranteed?

The mechanical design ensures that, when the locking cap is properly tightened, the internal compression creates a reliable seal rated for depths up to 100 m.

What are the advantages over glue-filled cable penetrators or Deep-Sea Cable Connectors?

This solution does not require potting or curing time. The seal is created by mechanical compression alone. It is more convenient, allows for disassembly, and provides a non-pluggable fixed cable exit — unlike Deep-Sea Cable Connectors, which are designed for repeated mating.

Is the depth rating theoretical?

No — the 100 m rating is based on real-world pressure testing. While not designed for deep-sea use, it offers reliable performance for shallow to moderate depth underwater projects.