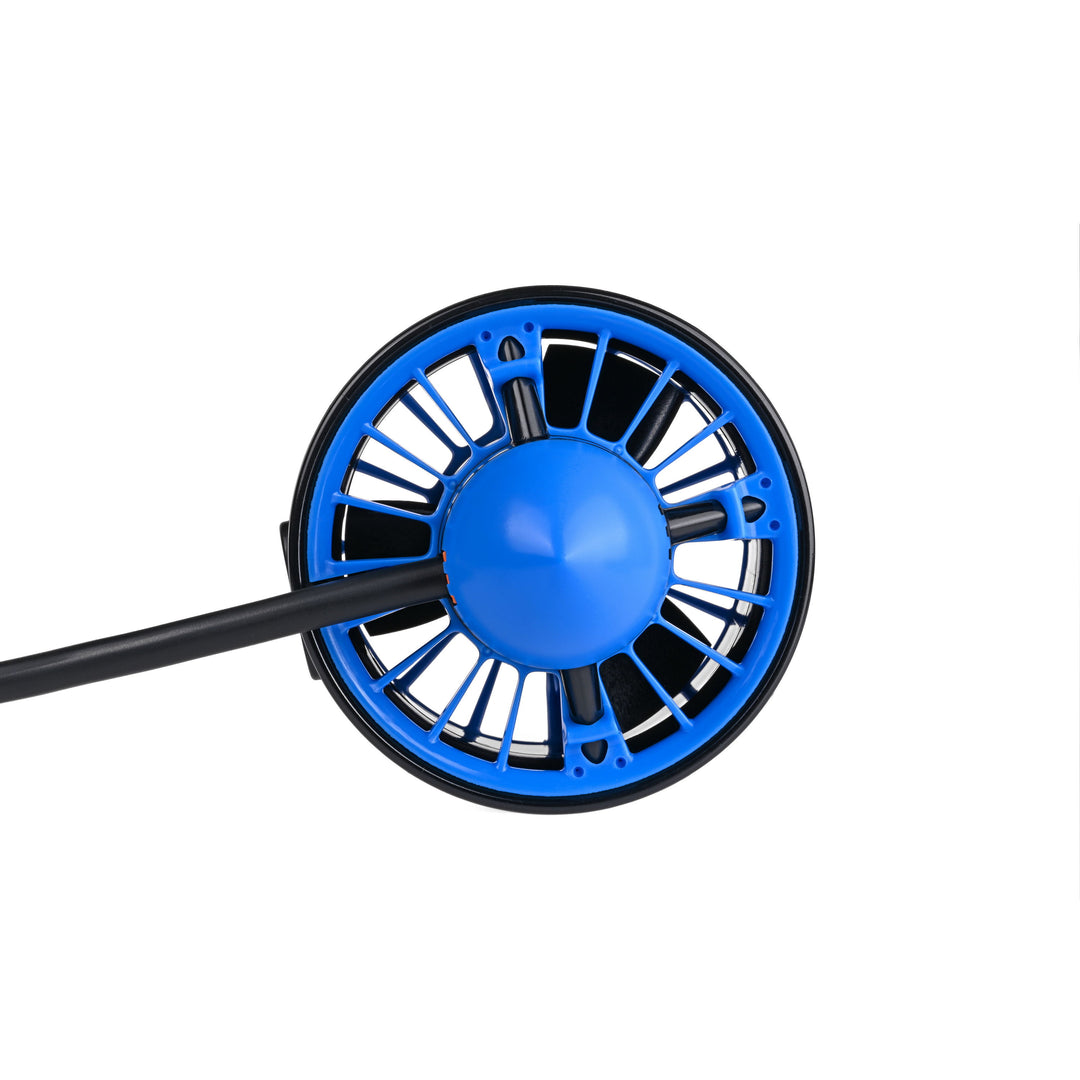

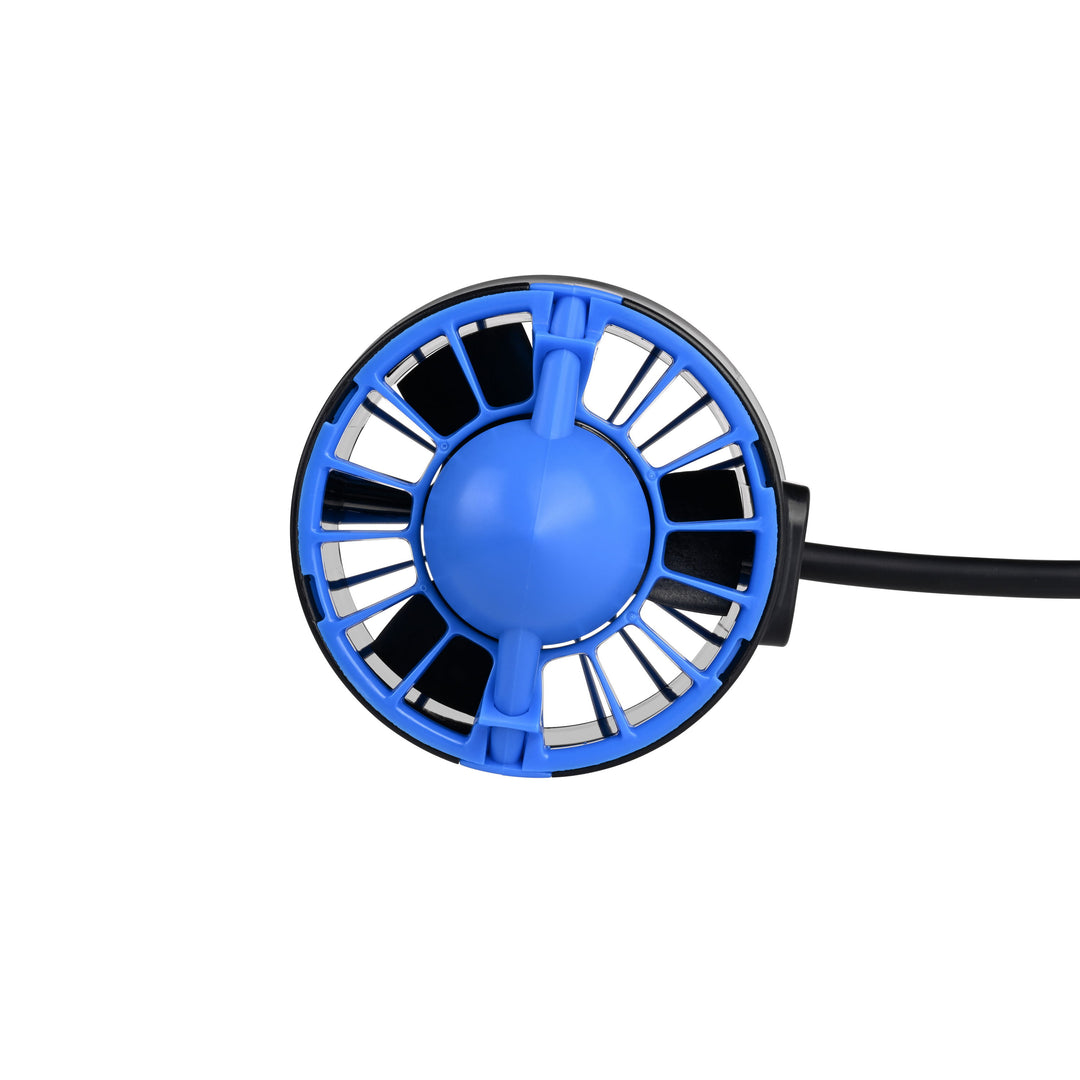

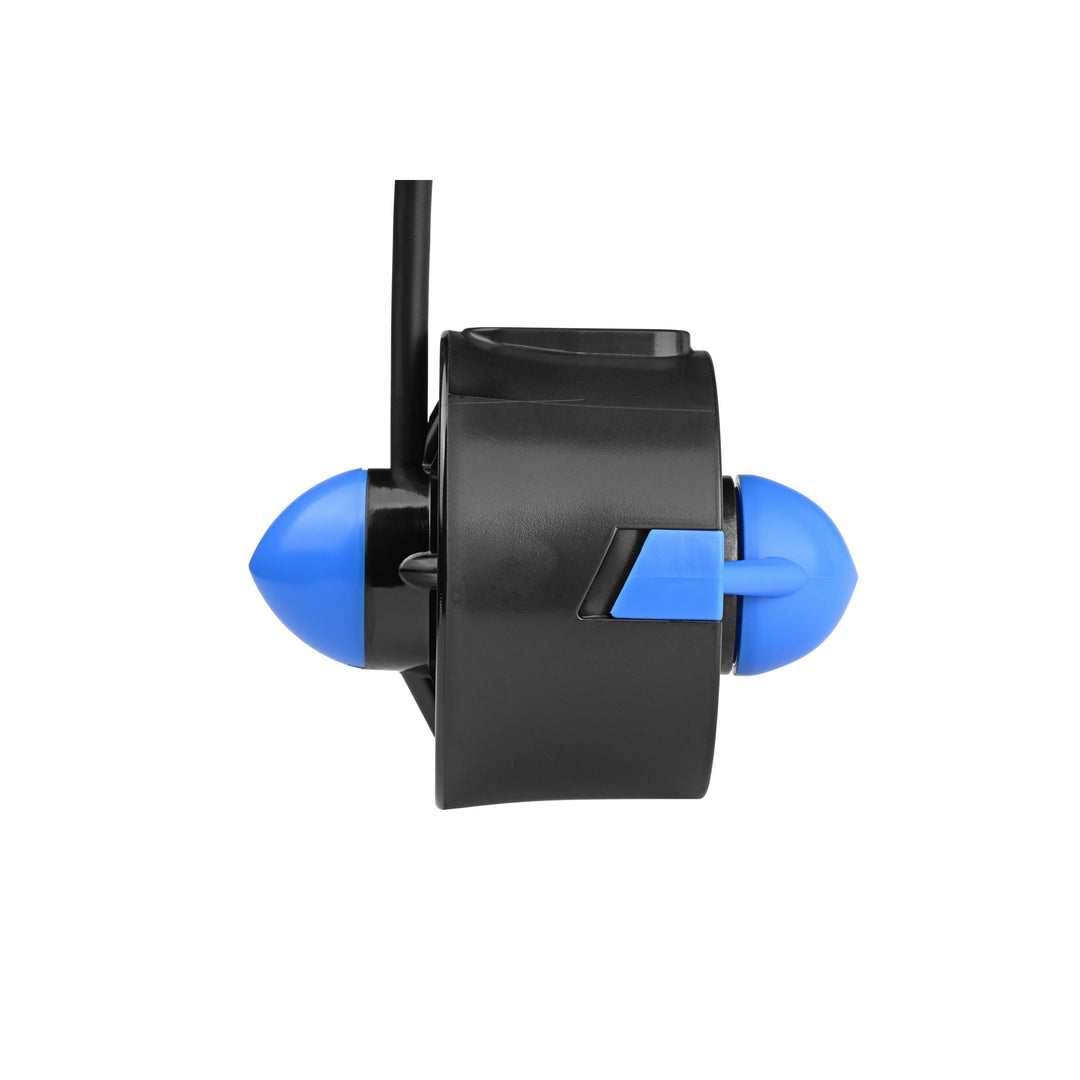

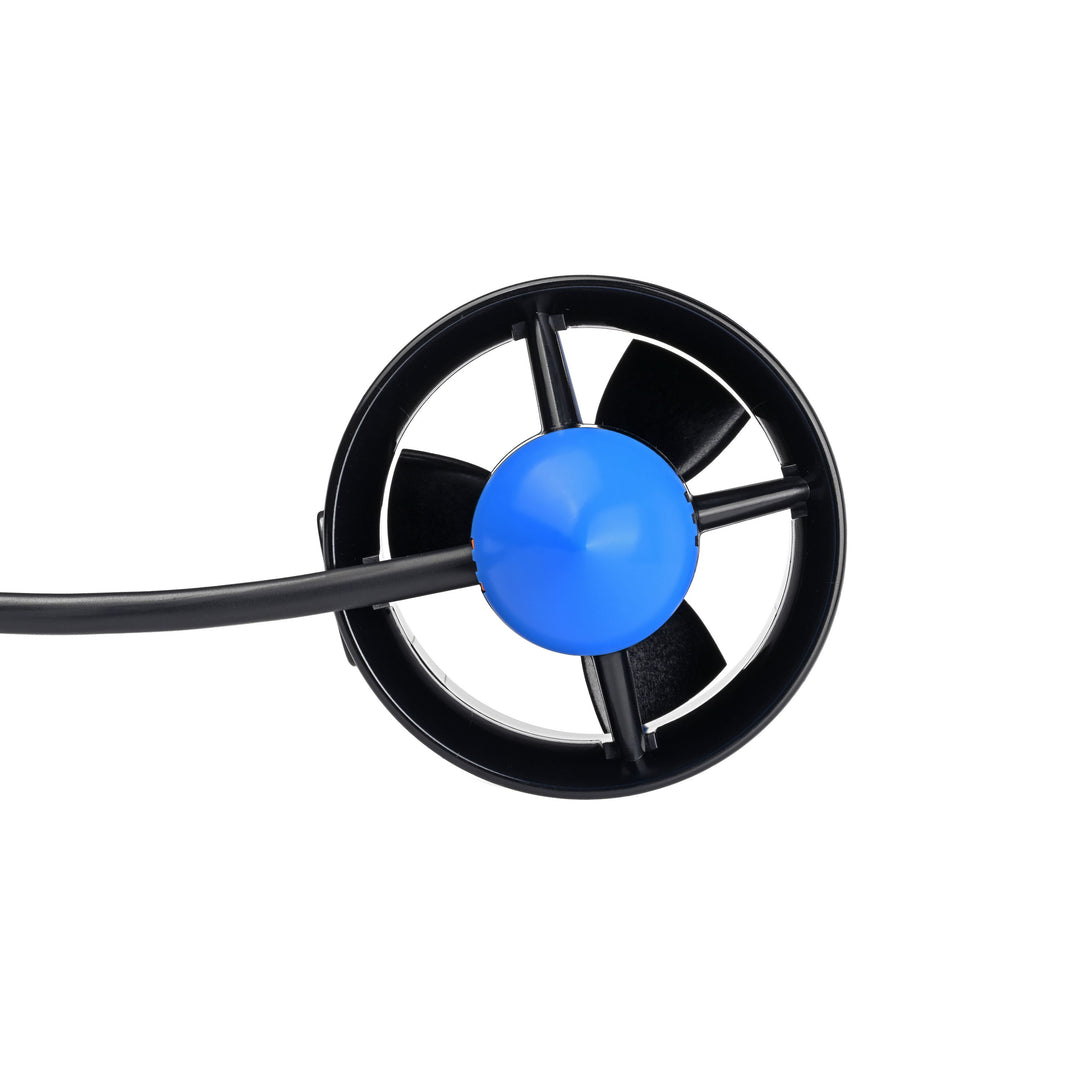

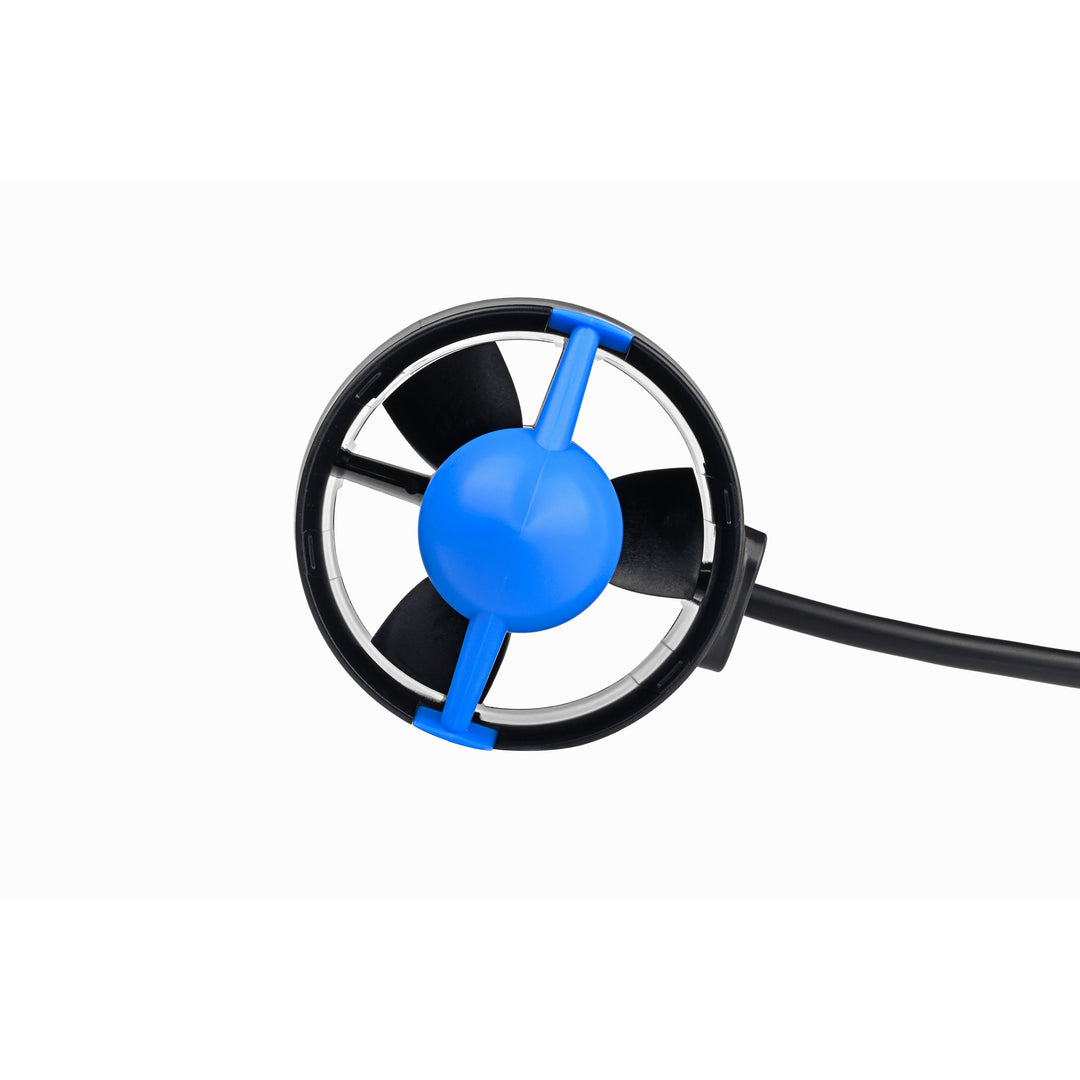

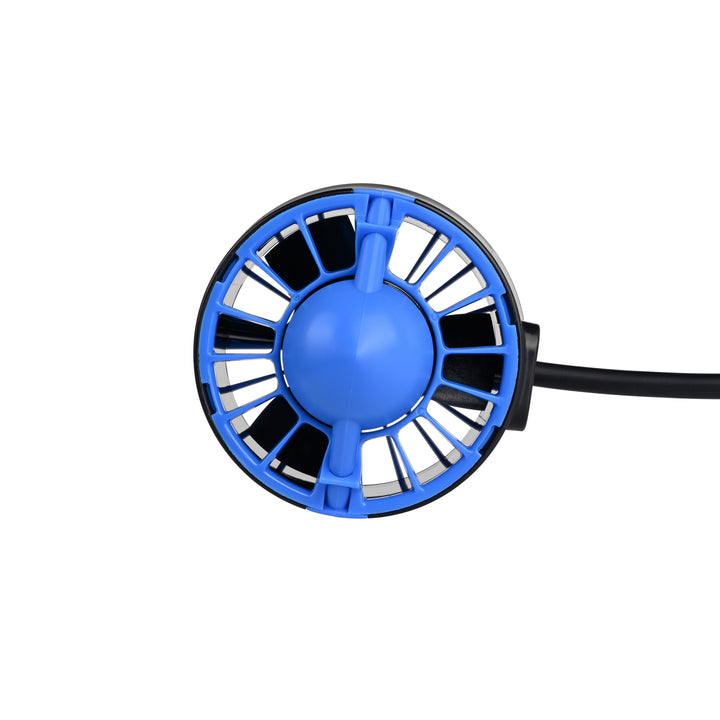

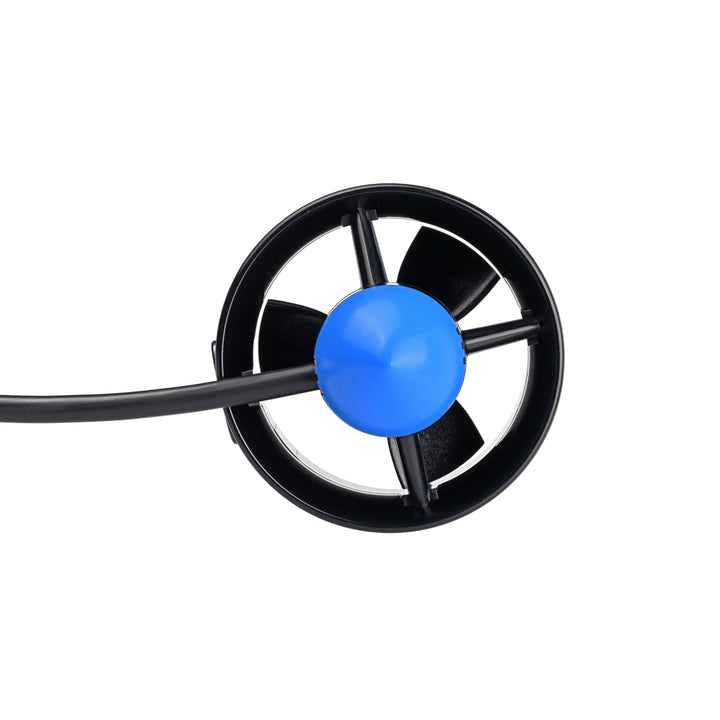

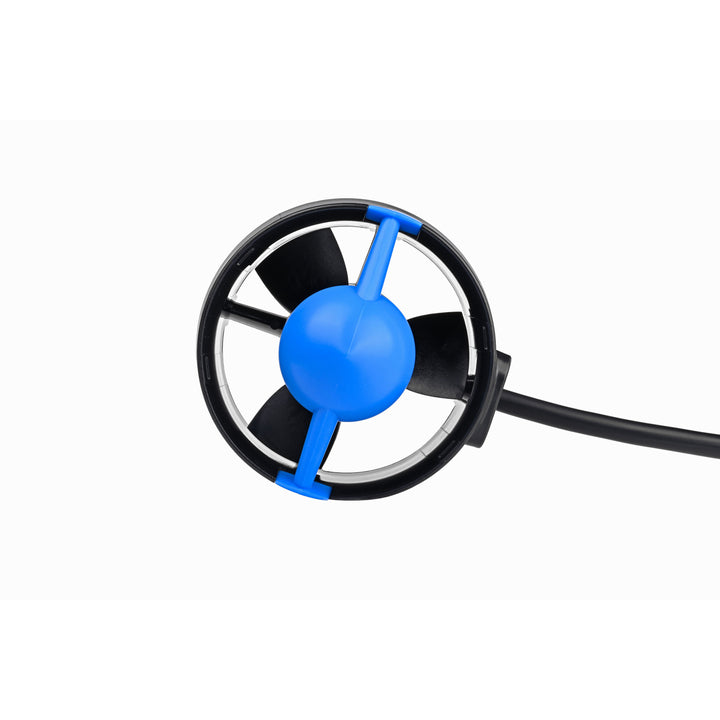

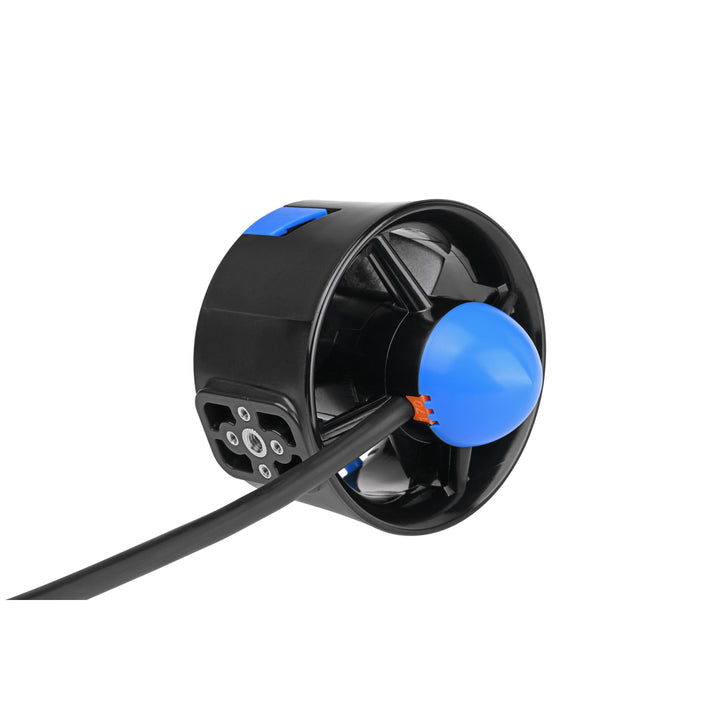

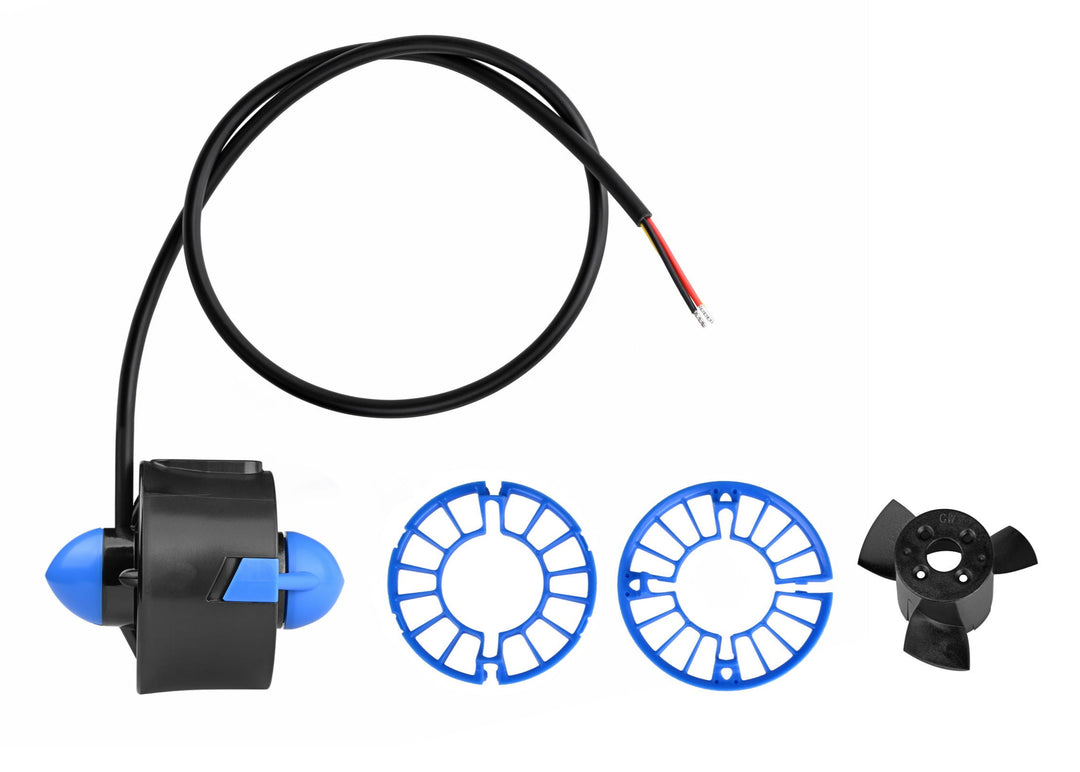

The Blu-Thrust Z80 Thruster is a compact, high-efficiency propulsion system designed for underwater vehicles operating at depths of up to 300 m / 984 ft. Its rugged construction features a selectively resin-encapsulated, electrically isolated brushless outrunner motor that allows direct water contact around the rotor for cooling, while protecting the stator windings and electrical interfaces through a combination of encapsulation and protective coatings. This approach delivers direct-drive thrust with minimal mechanical complexity and robust corrosion resistance in typical subsea operating environments.

The thruster is available in two variants with identical external dimensions and comparable thrust performance:

- Standard Version (Blu-Thrust Z80): Features a 3-core motor cable for external ESC connection. Ideal for integration with custom control electronics. A standalone external ESC board will be available soon for this model.

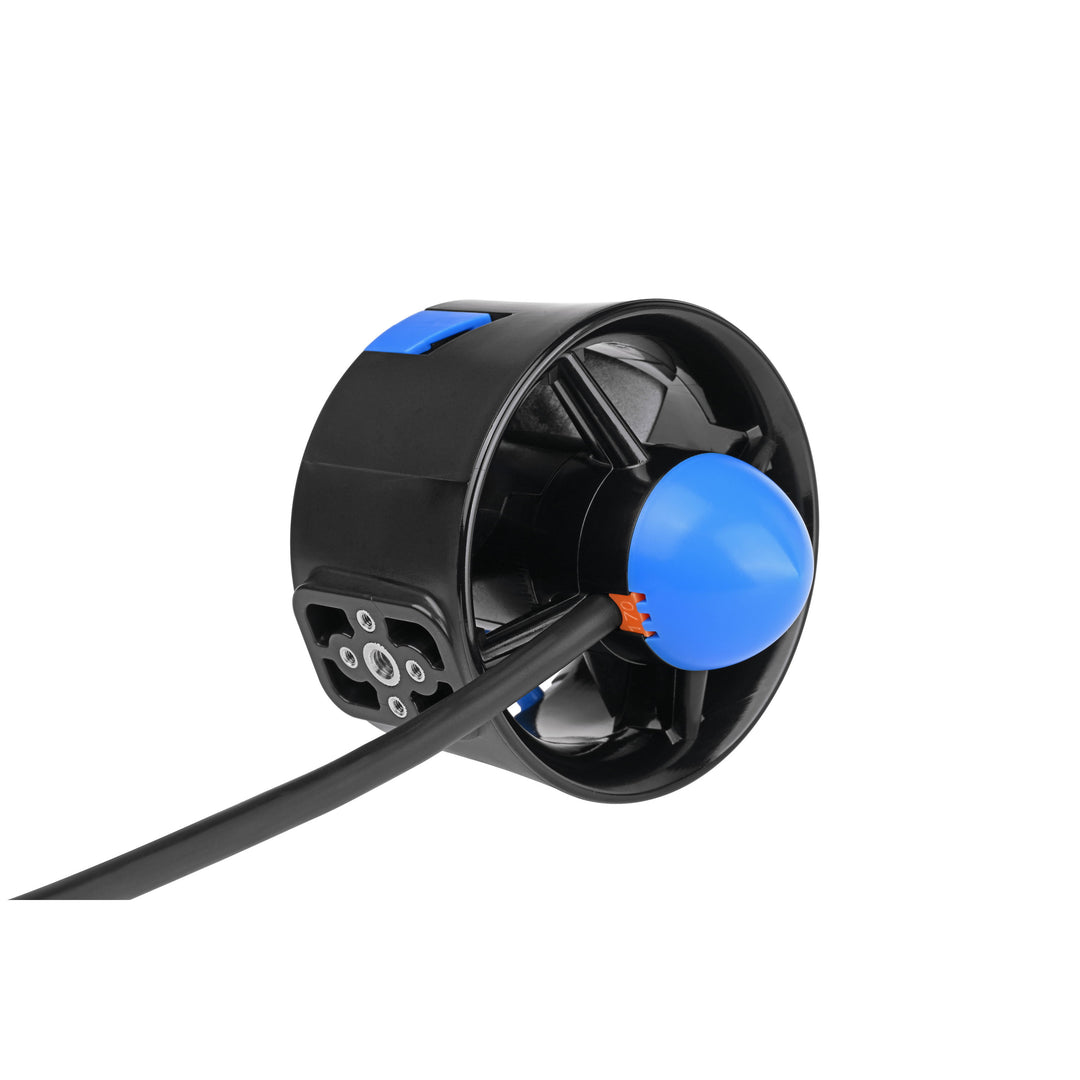

- Built-In ESC Version (Blu-Thrust Z80E): Incorporates an integrated trapezoidal ESC inside the thruster housing, simplifying wiring to Power (+), Power (–), and Signal. The grey housing allows quick visual identification, and the ESC’s exterior placement supports effective heat transfer to the surrounding water.

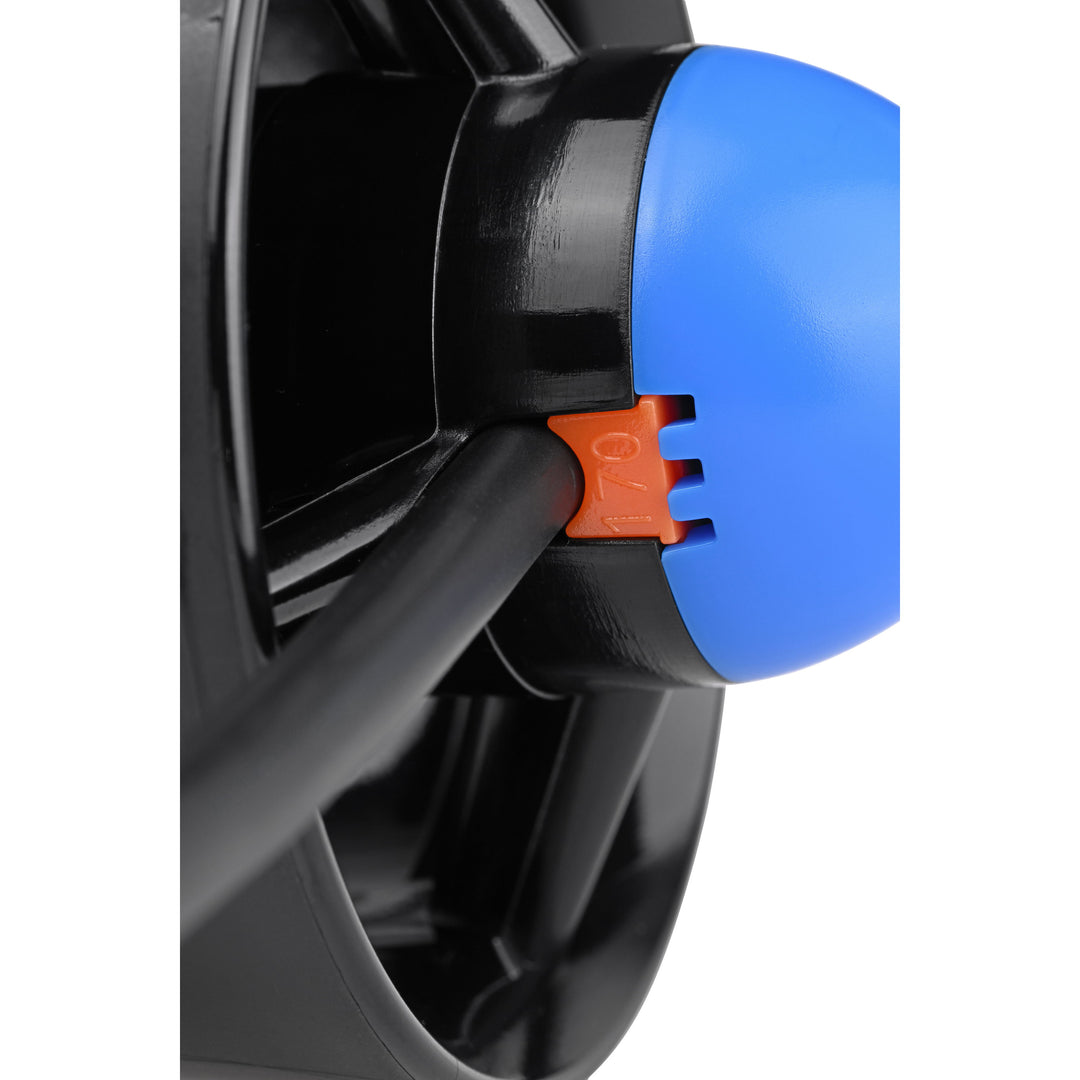

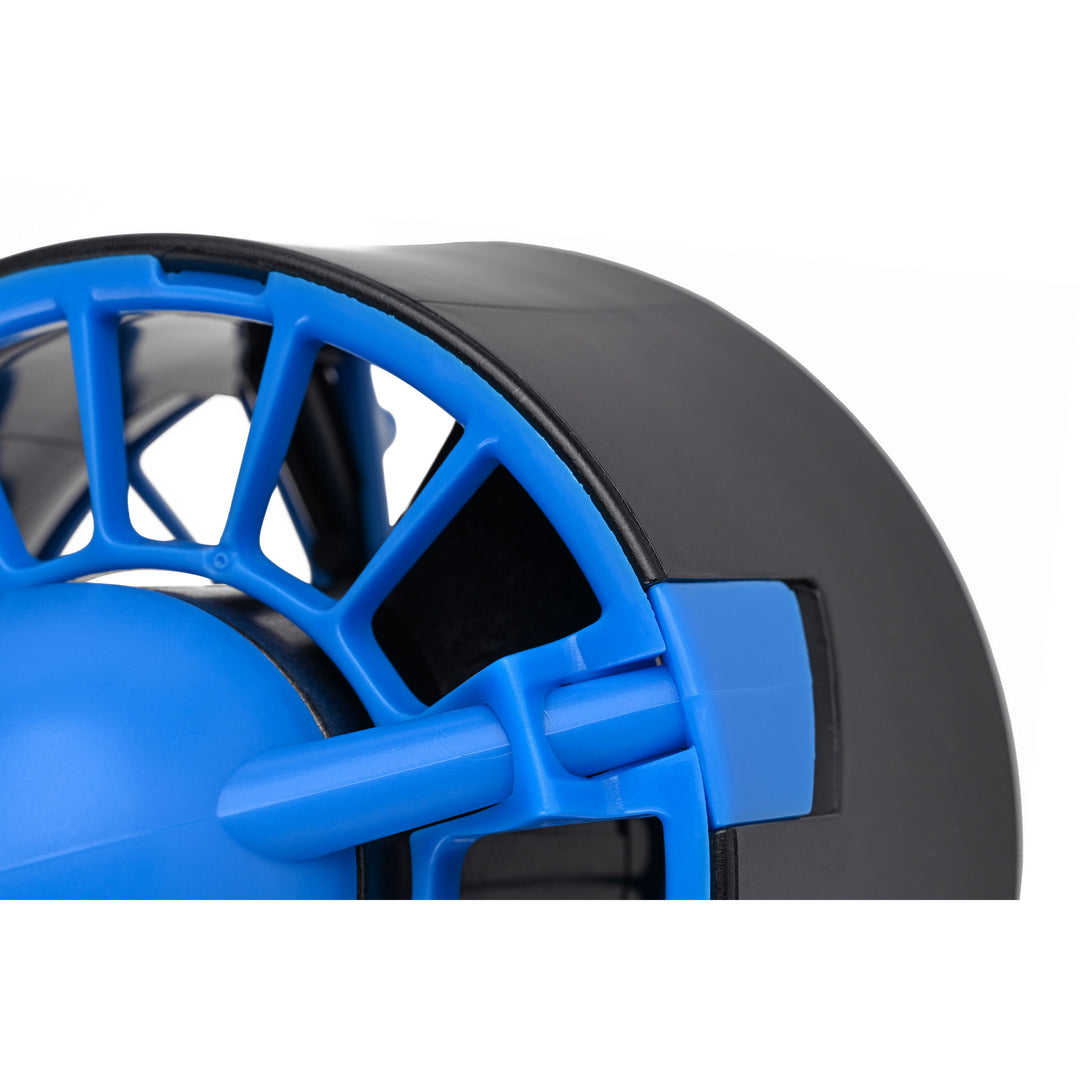

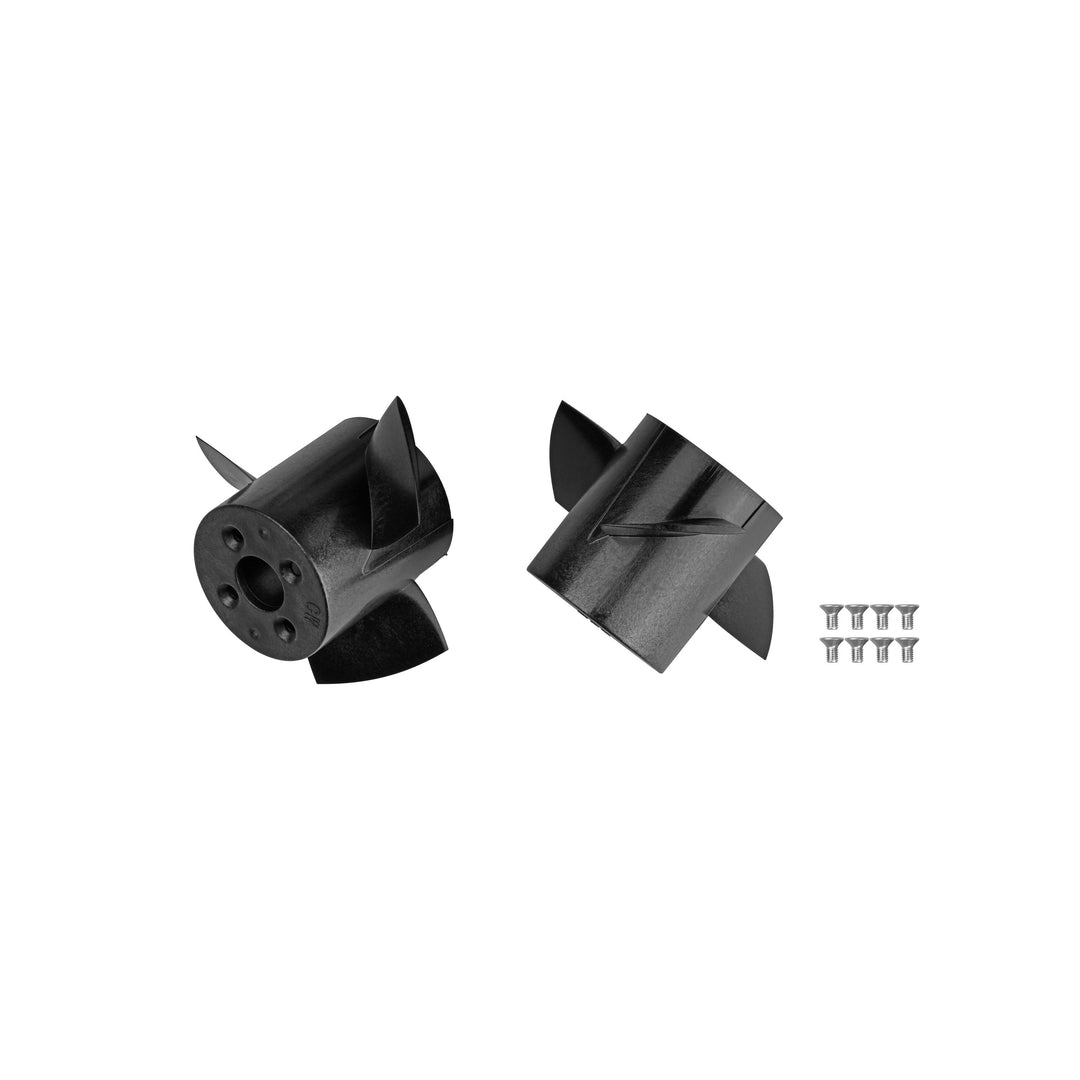

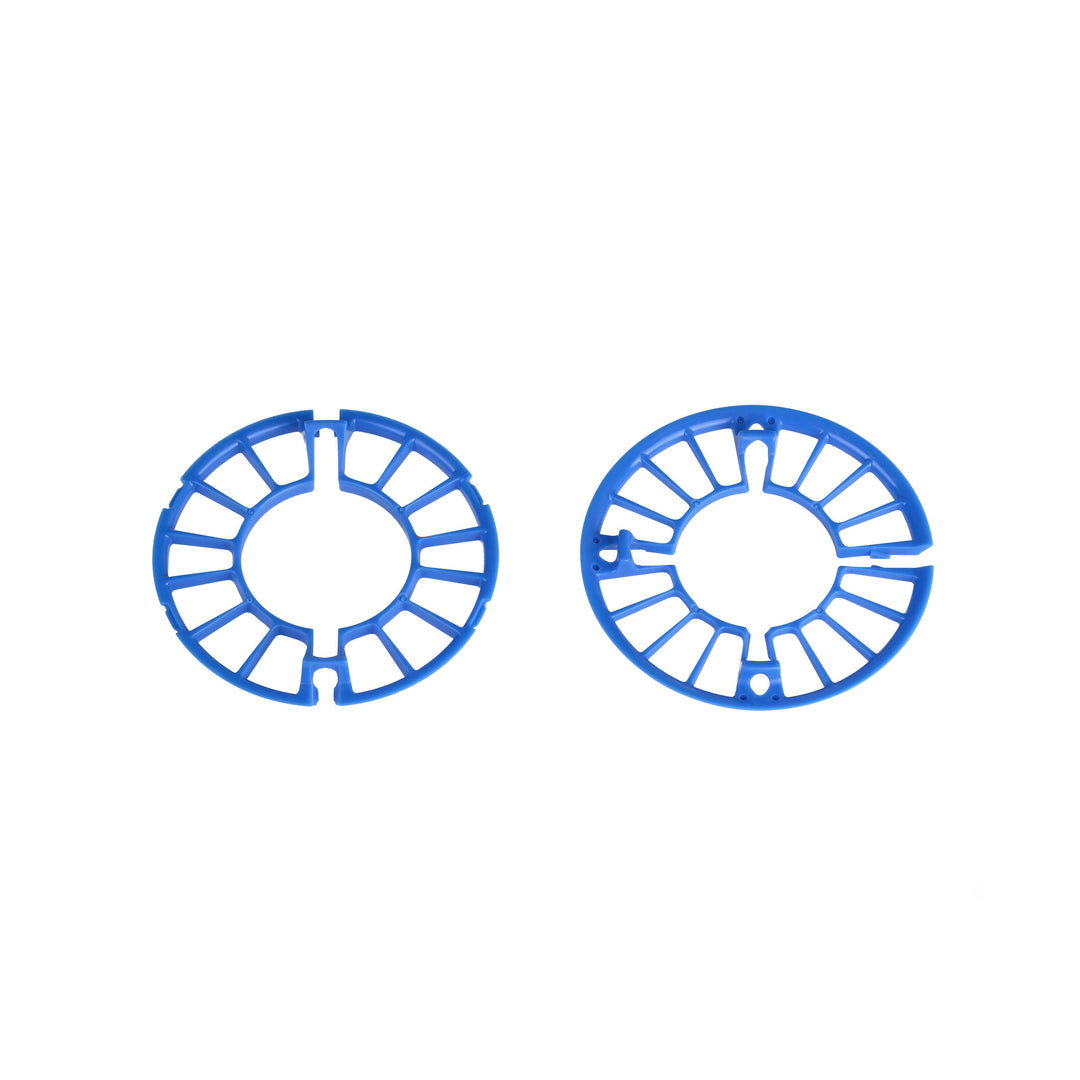

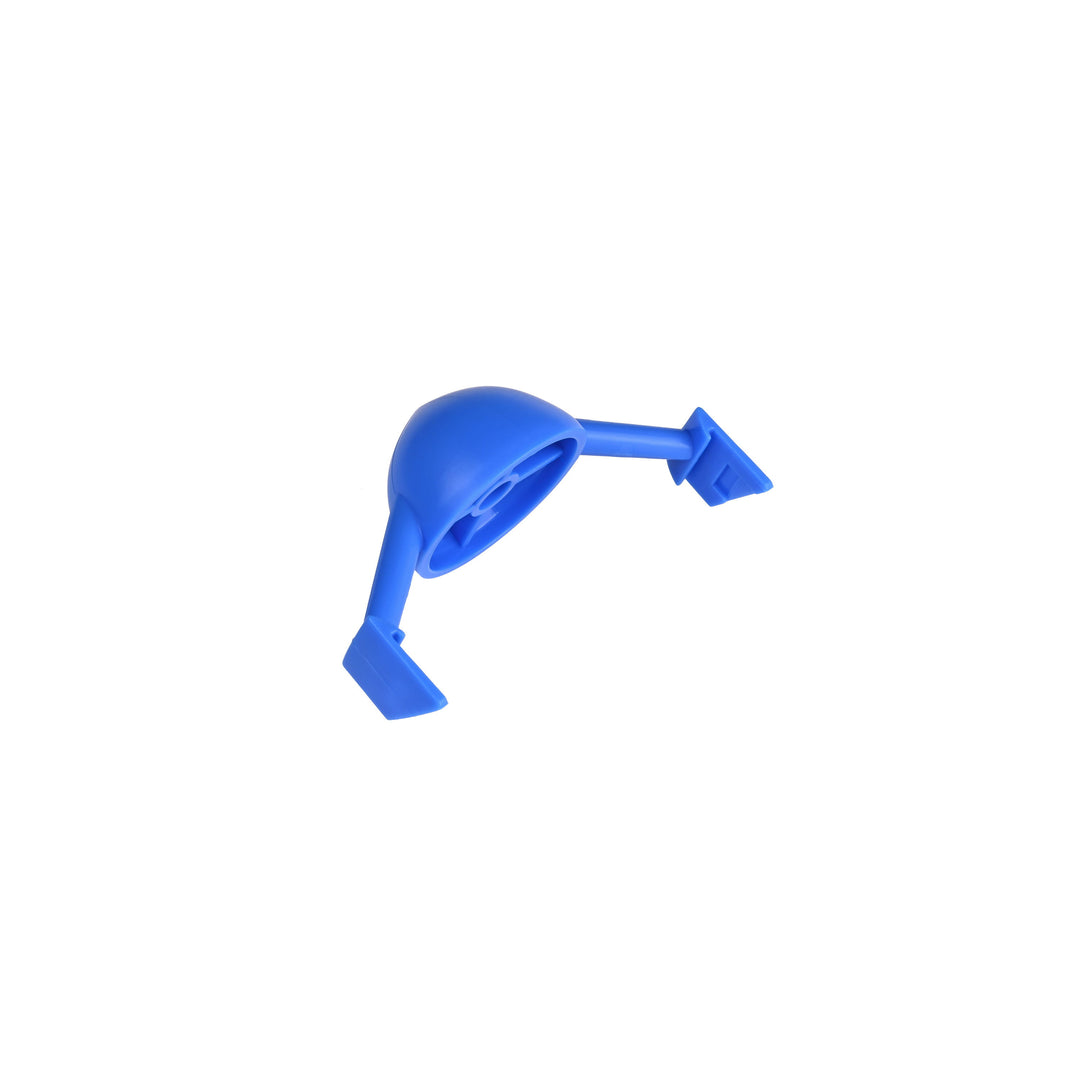

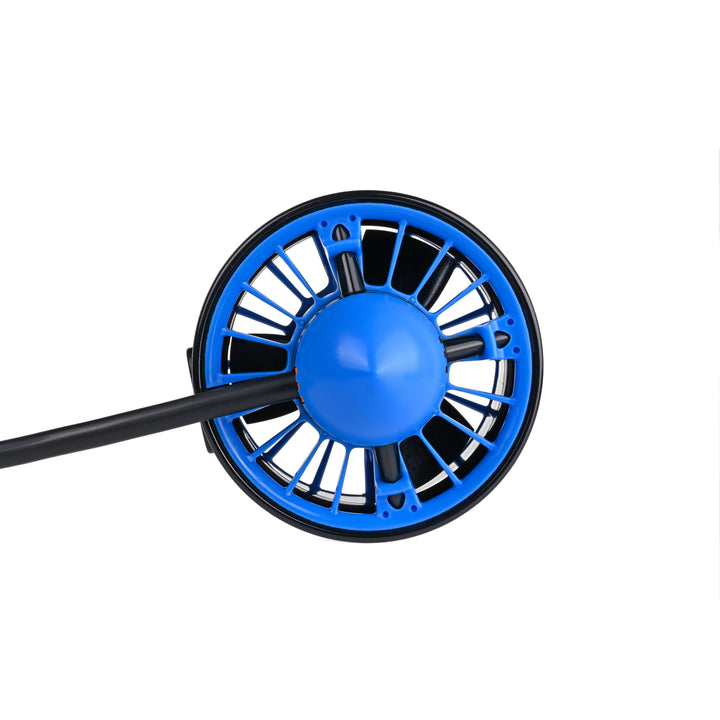

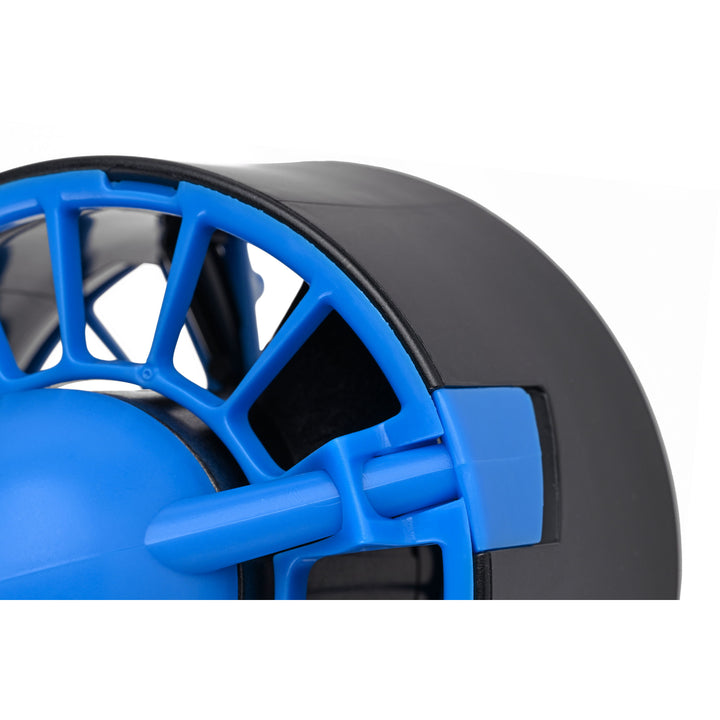

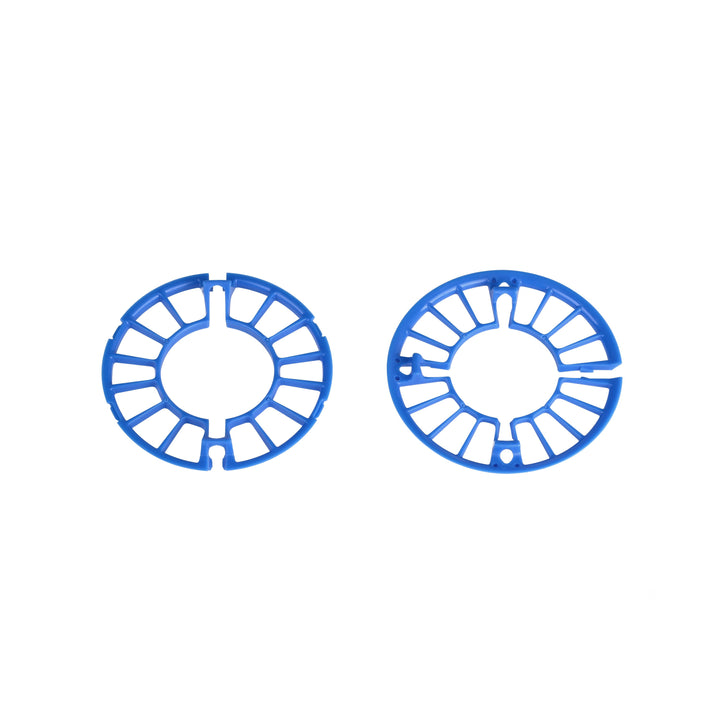

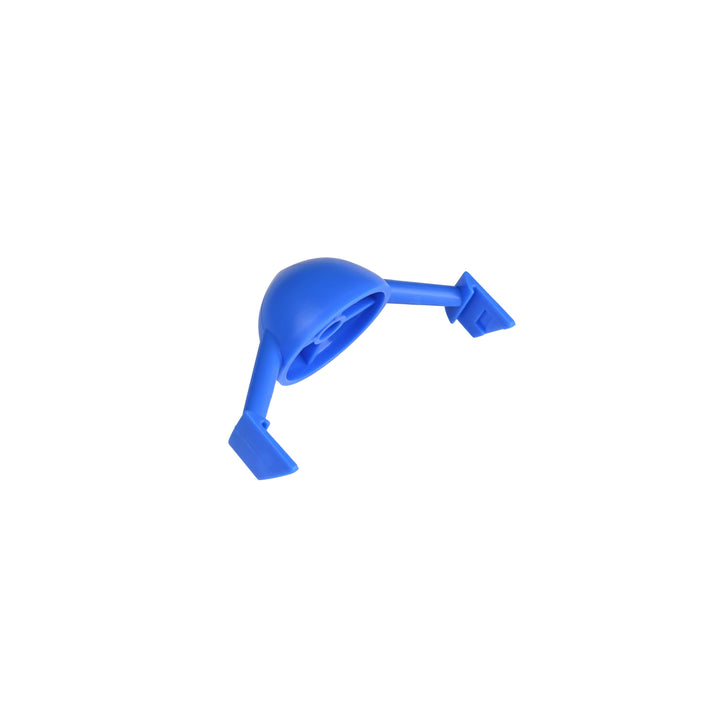

Each thruster includes a tool-free snap-on rear cap and a front weed-guard assembly designed for fast inspection and cleaning between dives. The front weed guard meets IP2X finger-protection requirements. Additional snap-on caps are available separately if replacements are required.

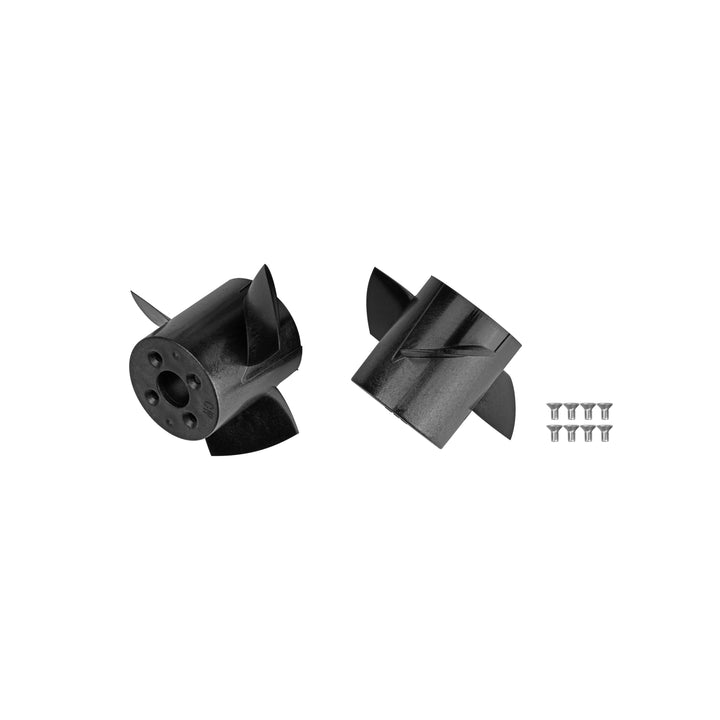

The optimized propeller and thrust-duct geometry provide strong forward and reverse performance, supported by simulation, real-world trials, and in-water testing. Each unit may retain minor water residue from testing and handling.

Durability testing has demonstrated >200 hours of continuous rotation under controlled fresh-water indoor conditions. The Blu-Thrust Z80 operates across a wide voltage input range (10 – 25.2 VDC). At 24 V, it delivers up to 5.3 kgf of forward thrust with just over 11 A of current under the stated test conditions. When the weed guard is installed, power consumption increases and thrust decreases; the guard is intended to improve protection in debris-prone environments and can be removed when maximum thrust is the priority.

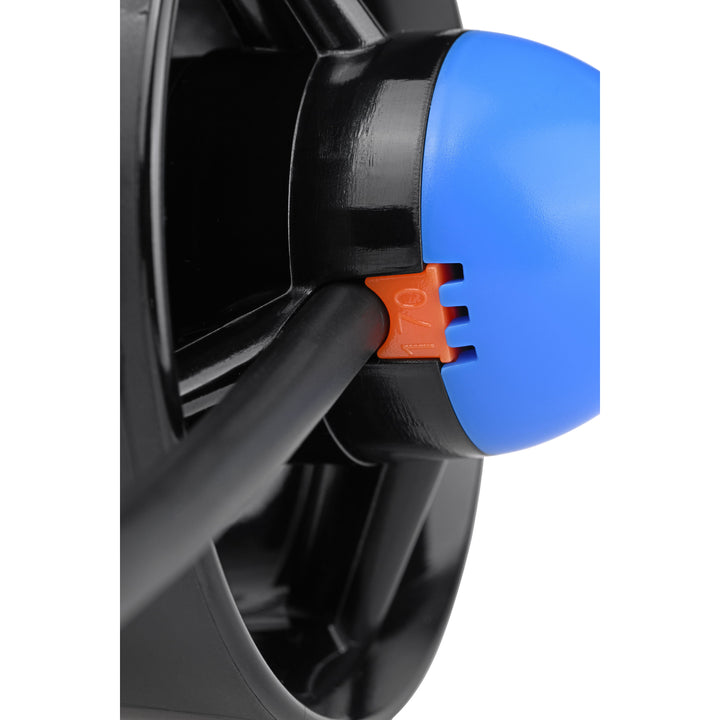

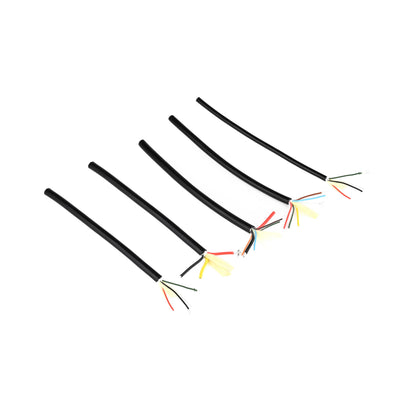

Wiring is straightforward using the included Deep-Sea 3-Core (16 AWG) Underwater Cable, which is pressure-rated for 300 m operation when installed with a compatible gland penetrator. The unit mounts via four M3 holes and a central M6 hole spaced at 19 mm, and is compatible with standard gland cable penetrators for watertight integration into your housing system. Suitable for both saltwater and freshwater environments, the thruster should be rinsed with clean water after use to help reduce corrosion risk.

Additional protection features include resilience against foreign object entry and impact. While the unit tolerates limited sand exposure, abrasive particles may accelerate wear—so fresh-water flushing is recommended after use in sediment-rich conditions. Its polycarbonate and stainless-steel construction is designed for durability under load and sustained immersion when operated within appropriate limits.

Note: A compatible cable penetrator is required to waterproof and secure the cable connection to your enclosure. This product uses the Deep-Sea 3-Core (16 AWG) Underwater Cable. Choose a penetrator below that matches your depth and housing requirements. Penetrator options are listed further below.

Sold Separately

Note: A compatible cable penetrator is required to waterproof and secure the cable connection to your enclosure. The Blu-Thrust Z80 Thruster is supplied with a Deep-Sea 3-Core (16 AWG) Underwater Cable, pressure-rated for 300 m / 984 ft operation when paired with the correct penetrator. Choose an option below that matches your depth rating and housing requirements.

Both the standard (non-ESC) and built-in ESC versions use the same 3-core cable type. The non-ESC version provides three motor phase wires for external ESC connection, while the built-in ESC version uses Power + / Power – / Signal wiring for direct control. A standalone external ESC board for the standard version will be available soon.

Blu-Sub offers several compatible cable penetrators designed to work with this thruster’s subsea power and signal cable, each suited for different underwater applications:

Deep-Sea Cable Penetrators – Standard, high-pressure design for deepwater, full-depth deployments. Depth Rating: Up to 1,000 m / 3,281 ft

Deep-Sea M10 Gland Cable Penetrators – M10-threaded penetrators with compression glands for secure strain relief and modular housing integration. Depth Rating: Up to 1,000 m / 3,281 ft

Low-Depth M10 Gland Cable Penetrators – Cost-effective, compact solution for shallow-water or low-pressure applications. Depth Rating: Up to 100 m / 328 ft

Sold Separately

About the Cable:

The Blu-Thrust Z80 Thruster is supplied with a Deep-Sea 3-Core (16 AWG) Underwater Cable, a rugged subsea cable designed for power and signal transmission to propulsion systems. Both thruster versions (standard non-ESC and built-in ESC) use the same cable type, with only the internal wiring configuration differing. A standalone external ESC board will soon be available for the non-ESC version, enabling plug-and-play installation using the same connector standard.

For modular setups, quick-disconnect capability, or extended cable runs, the following compatible connection options are available:

Deep-Sea Cable Connectors – Female Socket & Male Plug

Inline plug-and-socket connectors that allow the thruster’s cable to be terminated with sealed ends for removable, watertight propulsion connections.

Deep-Sea Cable Connectors – M10 Bulkhead

Panel-mounted connector designed for thruster cable pass-through on enclosure walls or end-caps. Requires a matching plug to form a sealed, high-pressure connection.

Deep-Sea Cable Connectors – Dummy Sealing Cap

Protects unused thruster cable connectors during storage, transport, or inactive operation by sealing off exposed ends against water ingress.

Subsea M10 Coupling Tube

Enables secure inline splicing of thruster cables using penetrators and potting compound.

Sold Separately

The Blu-Thrust Z80 Thruster is supplied with a Deep-Sea 3-Core (16 AWG) Underwater Cable, pressure-rated for 300 m / 984 ft when paired with a compatible cable penetrator. Once the cable is routed into your housing through the chosen penetrator, the thruster can be secured to your ROV frame or mounting structure using its built-in M3 and M6 mounting holes. Both the standard and built-in ESC versions share identical mounting dimensions and enclosure compatibility.

Subsea Watertight Enclosure Box

Compact aluminum enclosure rated to 300 m, pre-drilled with twenty M10 ports for penetrator installation—ideal for direct thruster cable pass-through without modification.

Subsea Enclosure Acrylic Tube

Transparent cast acrylic body rated to 250 m, compatible with Blu-Sub aluminum flanges and end-caps. Choose end-caps with penetrator ports to route thruster cables cleanly into the enclosure.

Subsea Enclosure Aluminum Tube

Rugged aluminum tube enclosure rated to 1,000 m. Use with matching deepwater-rated end-caps featuring penetrator ports for thruster cable integration in high-pressure environments.

| Item | Blu-Thrust Z80 Thruster (Z80 Standard & Z80E Built-In ESC Versions) |

| Material & Appearance |

Standard: PC Black + Blue Built-In ESC: PC Grey Propellers: PC + Glass Fiber Black Weed Guard & Snap-On Cap: PC Blue 316 Stainless Steel Inserts |

| Weight |

Thruster: 500 g Propeller Set: 34.2 g Weed Guard: 13.3 g Snap-On Cap: 14.3 g |

| Maximum Rated Depth | 300 m / 984 ft |

| Mechanical Endurance (Test Reference) | >200 hours (controlled freshwater testing) |

| Max Power |

Without Weed Guard: 300 W With Weed Guard: 335 W |

| 6S Full Throttle Current |

Forward: 11.9 A Reverse: 12.4 A With Weed Guard FWD: 13.2 A With Weed Guard REV: 13.3 A |

| 6S Full Throttle Thrust |

Forward: 5.6 kgf Reverse: 5.3 kgf With Weed Guard FWD: 3.2 kgf With Weed Guard REV: 3.1 kgf |

| Power Supply Voltage Range | 10 – 25.2 VDC |

| Rated Voltage | 24 V / 6S Battery |

| 24V Thrust Parameters |

FWD: 5.3 kgf / 266 W / 11.1 A REV: 4.6 kgf / 254 W / 10.6 A |

| Temperature Range |

Air: –25 °C to 60 °C Water: –10 °C to 40 °C |

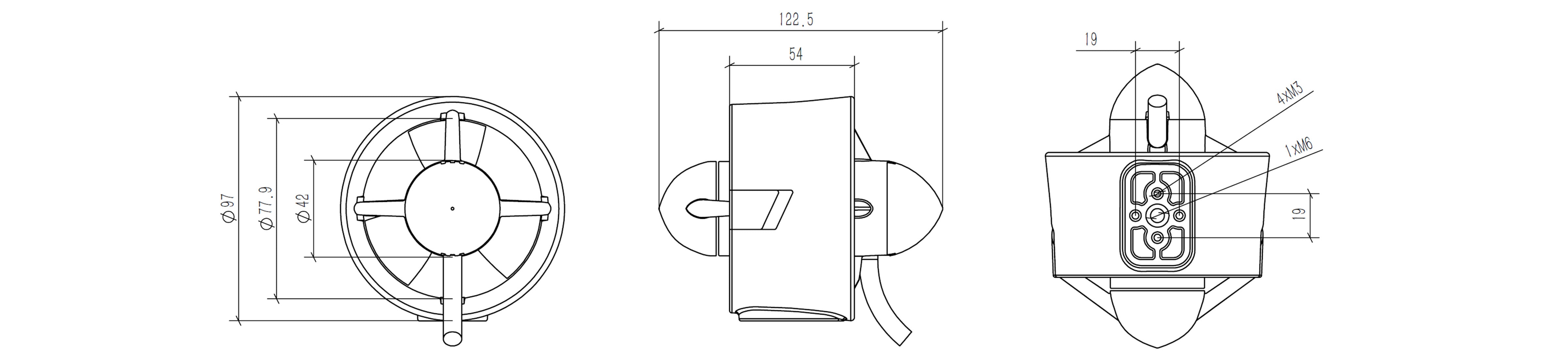

| Mounting Details |

Insert Nut Material: 316 Stainless Steel Mounting Threads: 4 × M3 + 1 × M6 Hole Spacing: 19 × 19 mm |

| Cable |

Length: ≈ 900 mm Spec: 3 × 16 AWG Standard Version: Motor phases (U, V, W) for external ESC Built-In ESC Version: Power (+) / Power (–) / Signal line Cable Type: Gland penetrator compatible, pressure-rated for 300 m |

| Motor |

Type: Outrunner Brushless Motor Pole-pairs: 8 KV Rating: ~170 Sealing: Selectively resin-encapsulated, electrically isolated, open-water-contact design Built-In ESC Version: Integrated Trapezoidal ESC |

* Performance parameters such as mechanical endurance and thrust are influenced by operating environment, duty cycle, and usage conditions, and may vary in real-world applications.

Full throttle thrust parameters at different voltages:

| Voltage (V) | Forward Thrust (kgf) | FWD Thrust Current (A) | Reverse Thrust (kgf) | REV Thrust Current (A) |

| 26 | 5.9 | 12.5 | 5.6 | 13.1 |

| 24 | 5.3 | 11.1 | 4.6 | 10.6 |

| 22 | 4.7 | 9.7 | 4.4 | 10.5 |

| 20 | 3.9 | 8.5 | 3.9 | 9.3 |

| 18 | 3.2 | 7.4 | 3.3 | 8.2 |

| 16 | 2.8 | 6.4 | 2.9 | 7.1 |

| 14 | 2.3 | 5.2 | 2.3 | 5.9 |

| 12 | 1.8 | 4.3 | 1.7 | 4.8 |

| 10 | 1.4 | 3.2 | 1.3 | 3.7 |

Data Curve:

* Thrust parameters are actual test data from Blu-Sub's proprietary test bench. Variations may occur across different test environments due to multiple factors. Due to a slight downward measurement bias in our test platform, data obtained from other test systems may generally be higher than those in this table. Note: When used with the weed guard, power consumption increases and thrust decreases measurably.

Performance Consistency:

Both the standard and built-in ESC versions share identical motor and hydrodynamic hardware. In our standard test configuration, thrust and efficiency are comparable across both models; differences relate primarily to wiring architecture and housing color. On the standard (non-ESC) version, measured current draw and response characteristics depend on the external ESC and tuning parameters.

Operational Lifecycle Considerations:

The Blu-Thrust Z80 is designed as a high-performance underwater propulsion component intended for active use in marine propulsion applications. Like all subsea thrusters, its operational lifespan is influenced by duty cycle, load conditions, water quality, operating depth, and maintenance practices. Controlled laboratory testing has demonstrated continuous rotation capability exceeding 200 hours under fresh-water, indoor conditions. Actual service duration in real-world deployments may vary depending on environmental exposure and usage profile. Routine inspection, cleaning, and appropriate operating limits are recommended to support consistent performance over time.

24V Thrust Curve:

24V Power Curve:

Wiring Definition (Blu-Thrust Z80 — Non-ESC Models):

Wiring Definition (Blu-Thrust Z80E — Built-In ESC Models):

Rotation Direction, Thrust Direction, and Forward/Reverse Propeller Direction Description:

If you require a pre-installed gland penetrator with a specified cable length, please contact us and provide the A and B dimensions as shown in the figure below. The penetrator is pressure-rated for 300 m and uses an integrated compression plug and sleeve ring for sealing. We will respond with lead times and price implications, as these may be extended for custom wiring lengths. Generally, the combined A + B measurement should be less than 850 mm.

What is the difference between the standard and built-in ESC versions?

Both versions share identical external dimensions and comparable thrust performance. The standard model (Blu-Thrust Z80) connects to an external ESC via its 3-core cable, while the built-in ESC version (Blu-Thrust Z80E) integrates a trapezoidal ESC inside the housing, simplifying wiring to Power (+), Power (–), and Signal. The Z80E version also uses a grey housing for easy identification.

Is the thruster repairable if damaged or miswired?

No. Both versions use selective encapsulation and protective coatings and are not intended to be user-serviceable. Damage from overvoltage, reverse polarity, incorrect ESC configuration, or severe mechanical shock typically requires replacement rather than repair.

Why are there CW/CCW propellers?

The CW (clockwise) and CCW (counterclockwise) propellers are mirror-image designs used to help balance reactive torque when multiple thrusters are installed. For example, if all thrusters generate thrust with the same propeller rotation direction, the net torque applied to the vehicle can cause undesired yaw. Using a mix of CW and CCW propellers helps reduce this effect and improve handling.

Can the front cap be removed?

No. The front assembly is fixed, while the rear snap-on cap is designed to be detachable for cleaning or inspection.

Will foreign object insertion or forced blockage cause permanent damage?

It can. Severe blockage—especially debris entanglement or forced rotor stoppage—may overload the motor and/or ESC and can cause permanent damage.

Is it suitable for sandy underwater environments?

The thruster offers some sand tolerance, but fine abrasive particles may still enter and accelerate wear. After operating in sandy or silty conditions, promptly flush the rotating components with fresh water to minimize abrasive buildup and reduce long-term wear.

Can it be used in both saltwater and freshwater?

Yes, it is compatible with both. After use in saltwater, promptly soak and rinse with fresh water to remove salt residue and help reduce corrosion risk or mechanical seizure.

What is the expected service life?

In laboratory testing, the thruster demonstrated over 200 hours of continuous rotation in freshwater under controlled indoor conditions. Actual service life varies with duty cycle, load, water quality, operating environment, and maintenance practices.

Can it operate in air?

Yes. The Blu-Thrust Z80 and Blu-Thrust Z80E can operate in air. For extended high-power operation, allow for adequate cooling and avoid sustained stall or blockage conditions.